A kind of method for preparing titanium nitride nano film on the surface of substrate, substrate with film and application thereof

A titanium nitride nanometer and substrate technology, which is applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem that the surface conformality needs to be enhanced, the bonding strength between the film and the substrate is low, and it cannot be realized. Complex structure and other problems, to achieve the effect of reducing the secondary electron emission coefficient, strong controllability of reaction parameters, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

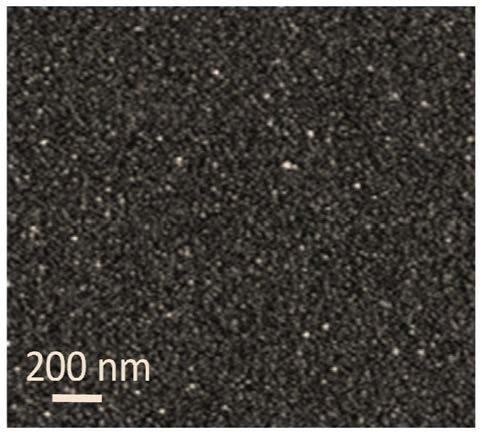

[0057] This embodiment provides a metal aluminum substrate with a titanium nitride nano-film, and its preparation method comprises the following steps:

[0058] (1) After ultrasonically cleaning and drying the flat metal aluminum substrate with alcohol, the substrate is transferred to the reaction chamber through the pre-vacuum chamber, and the reaction chamber is evacuated to 1Pa;

[0059] (2) Introduce high-purity nitrogen gas with a purity of 99.99% into the reaction chamber, maintain the air pressure at 40 Pa, heat the reaction chamber to 200° C., and keep it warm for 30 minutes to anneal the substrate;

[0060] (3) Return the annealed substrate to the pre-vacuum chamber, use tetrakis(dimethylamino)titanium as the titanium source, heat the titanium source and the titanium source gas path to 100°C, stabilize for 10min, and then use The ammonia gas plasma and the titanium source carry out 15 scrubbing cycles, wherein, in each of the scrubbing cycles, the flow rate of the amm...

Embodiment 2

[0064] This embodiment provides a metal aluminum substrate with a titanium nitride nano-film, the preparation method of which is basically the same as that of embodiment 1, the only difference is that 20 plasma-enhanced titanium nitride atoms are carried out in step (4). layer deposition cycle.

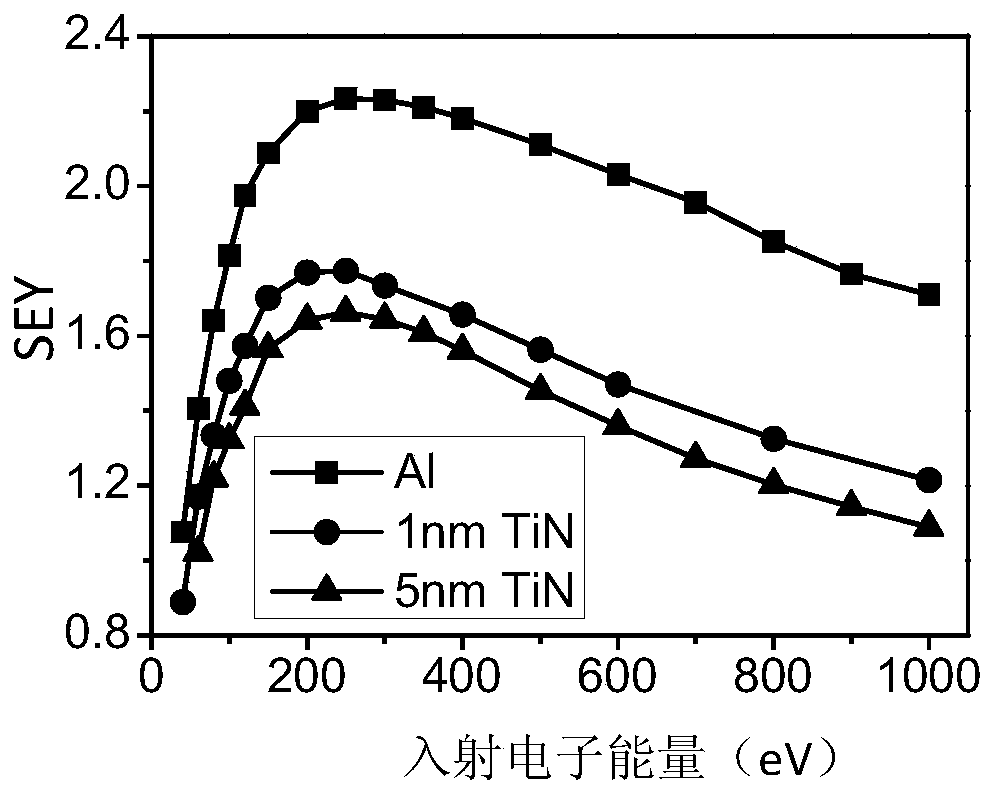

[0065] In the embodiment of the present invention, the thickness of the titanium nitride nanofilm is 2nm, and the secondary electron emission coefficient of the aluminum substrate used in the embodiment of the present invention and the aluminum substrate with the titanium nitride nanofilm is measured by the current method. The secondary electron emission coefficient of the sheet is 2.35, and the secondary electron emission coefficient of the aluminum substrate with titanium nitride nano film is 1.70.

Embodiment 3

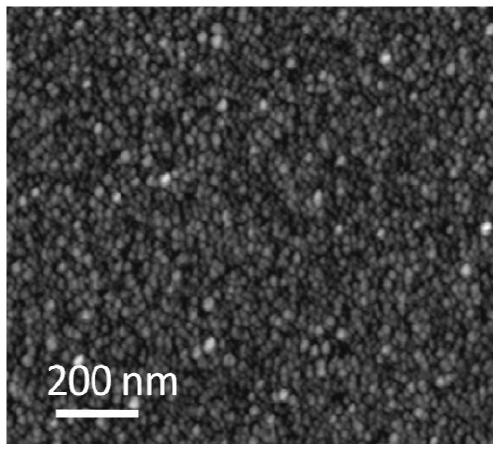

[0067] This embodiment provides a metal aluminum substrate with a titanium nitride nano-film, the preparation method of which is basically the same as that of embodiment 1, the only difference is that 40 plasma-enhanced titanium nitride atoms are carried out in step (4). layer deposition cycle.

[0068] In the embodiment of the present invention, the thickness of the titanium nitride nanofilm is 5nm, and the secondary electron emission coefficient of the aluminum substrate used in the embodiment of the present invention and the aluminum substrate with the titanium nitride nanofilm is measured by the current method, as image 3 As shown, the secondary electron emission coefficient of the aluminum substrate used is 2.35, and the secondary electron emission coefficient of the aluminum substrate with titanium nitride nano film is 1.65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com