Method for processing ammonia-nitrogen wastewater

A technology for ammonia nitrogen wastewater and wastewater, applied in the direction of anaerobic digestion treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problem of increasing the pH value of the solution, reducing the activity and reproduction speed of anammox bacteria, and reducing wastewater treatment capacity and other issues, to achieve the effect of high denitrification efficiency, conducive to mass growth and reproduction, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

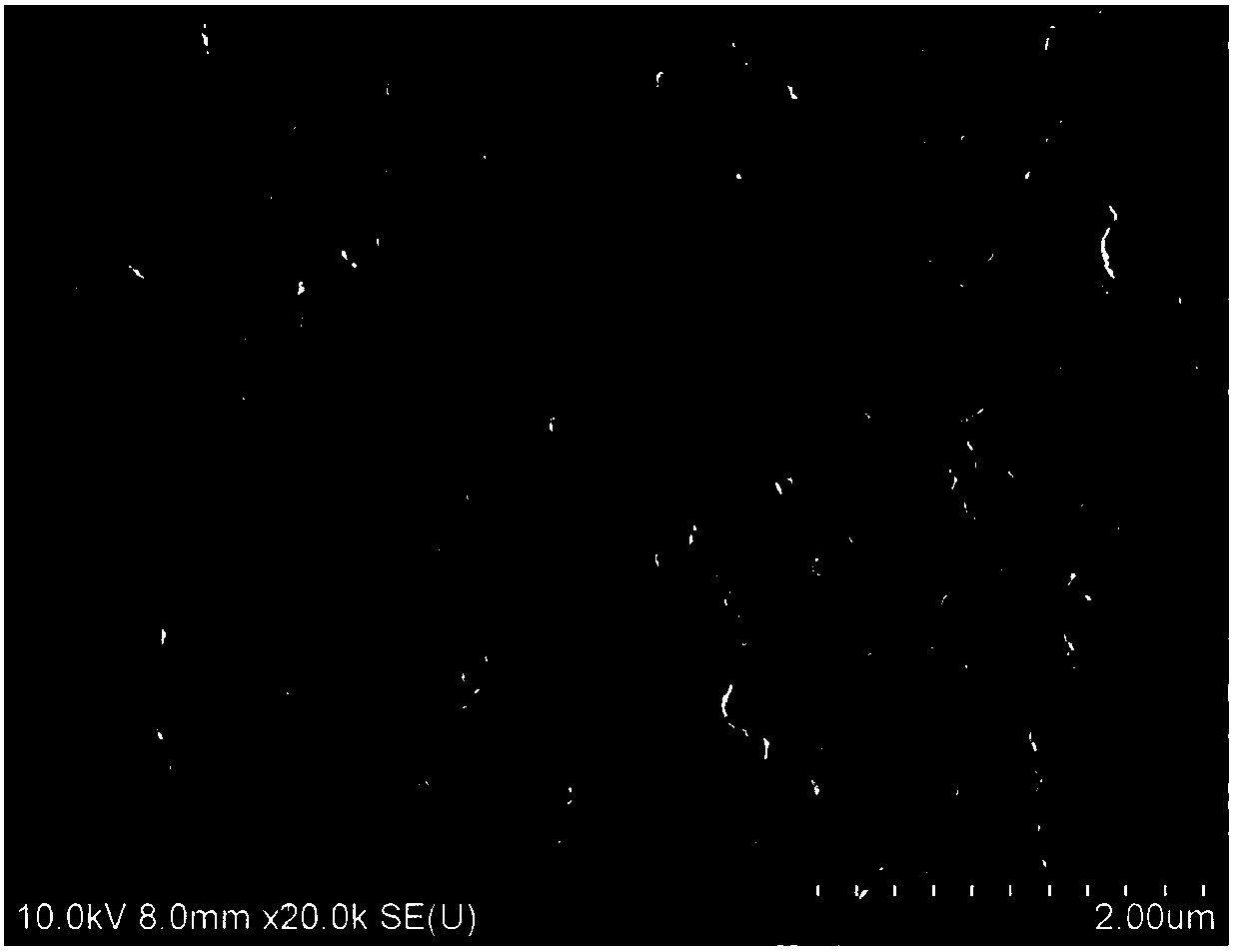

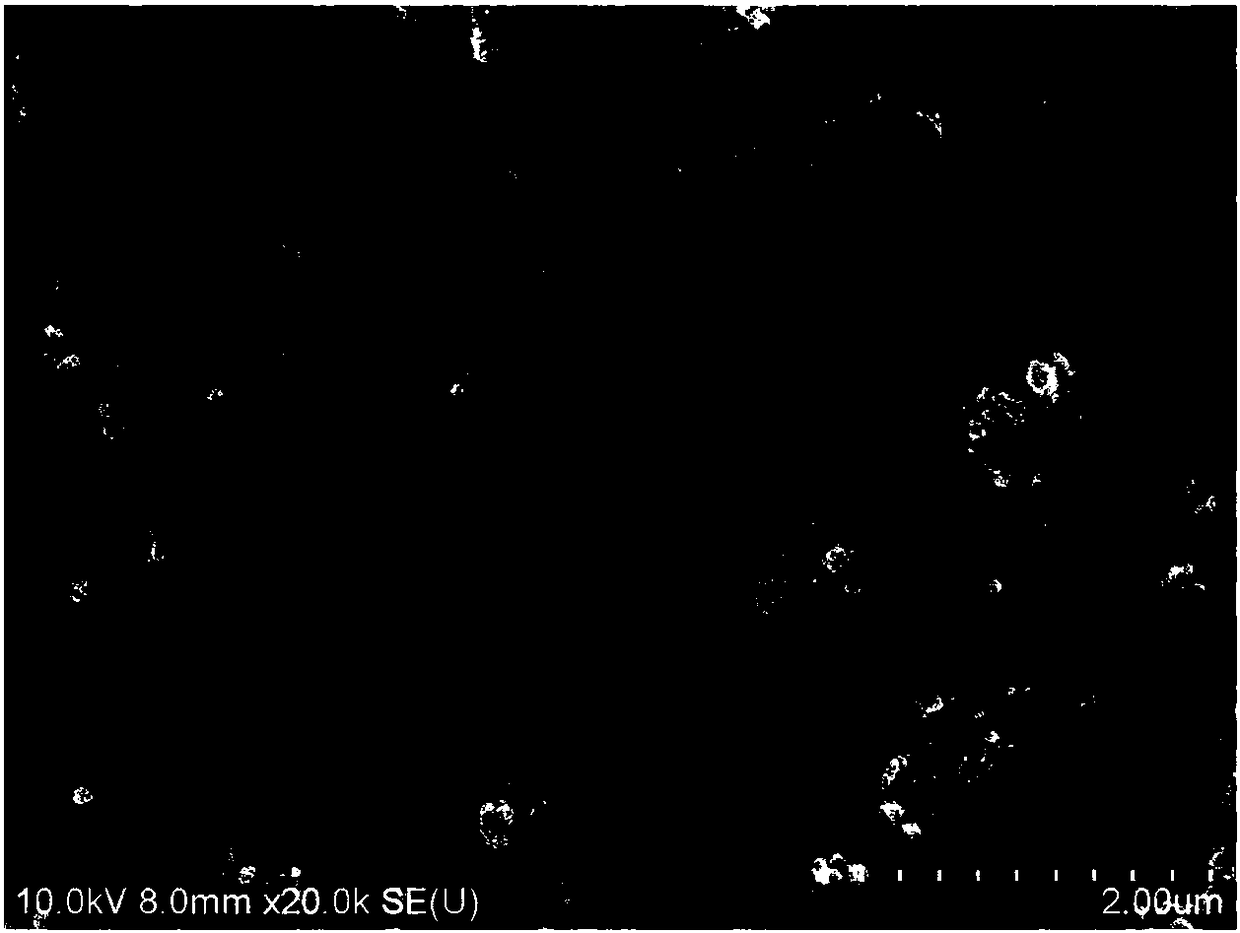

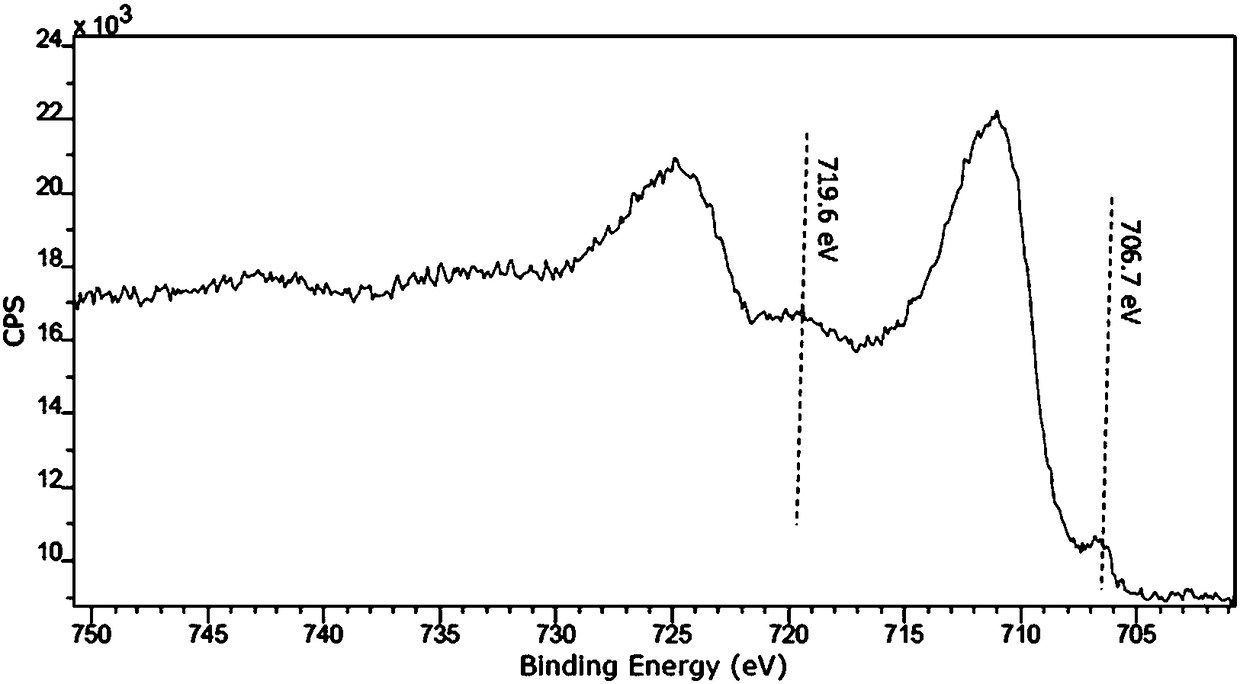

[0040] This embodiment relates to the preparation of zero-valent iron loaded on montmorillonite, comprising the following steps:

[0041] 1) Configure 40g / L montmorillonite suspension, dissolve 9.6g ferric chloride hexahydrate in water, and prepare ferric chloride solution;

[0042] 2) Under the protection of nitrogen, add the ferric chloride solution to 50mL of montmorillonite suspension, stir until evenly mixed, then add 100mL of 1M sodium borohydride aqueous solution, stir quickly until the reaction is complete, and filter with suction , washed with pure water, and vacuum-dried at 50-80° C. to obtain zero-valent iron (MMT-ZVI) supported on montmorillonite.

Embodiment 2

[0044] This embodiment relates to the operation of utilizing the method of the present invention to treat nitrogen-containing wastewater, comprising the following steps:

[0045] 1) The ferric chloride and 10g MLSS anaerobic ammonium oxidation sludge prepared by the 5g montmorillonite load prepared in embodiment 1 are added in the 5L SBR (sequencing batch type) reactor, add the wastewater to be treated, ammonia nitrogen and The initial concentration of nitrite nitrogen is 53mg / L and 50mg / L respectively, the concentration of sludge after adding wastewater is 2g MLSS / L, and the concentration of montmorillonite loaded with zero-valent iron carrier is 1g / L;

[0046] 2) An anaerobic environment is maintained in the SBR reactor, the temperature is controlled at 37°C, the hydraulic retention time is 36h, the water exchange ratio is 2, and a cycle is 18h, in which the water outlet time is 10min, the water inlet time is 20min, and the precipitation time is 30 minutes. Stir The reaction...

Embodiment 3

[0049] Compared with Example 2, the difference is that the added amount of the montmorillonite loaded with zero-valent iron is 0.2g, that is, its concentration in the wastewater is 0.04g / L.

[0050] The monitoring result of the effluent in the 18th hour was that the pH of the effluent was 7.9, the concentration of ammonia nitrogen was 25 mg / L, the removal rate dropped to 52%, the concentration of nitrite nitrogen was 15, the removal rate was 70%, the concentration of nitrate nitrogen was 9 mg / L, and the total nitrogen The removal rate was reduced to 52.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com