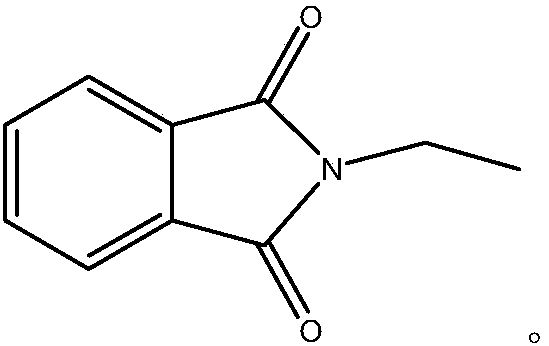

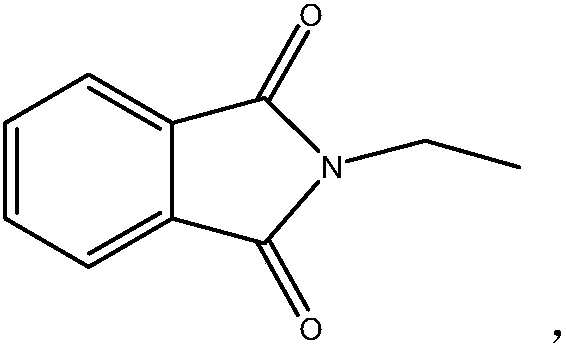

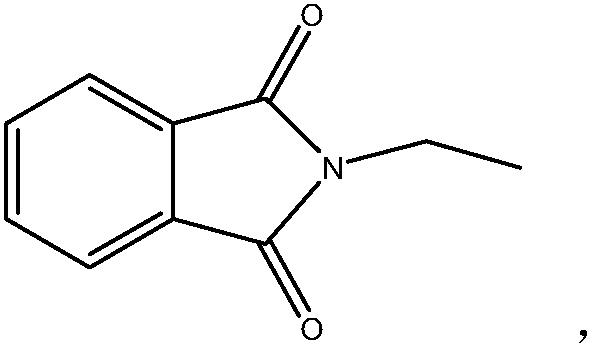

Synthetic method of industrial additive N-ethyl phthalimide

A technology of ethyl phthalimide and phthalimide, which is applied in the field of synthesis of new industrial auxiliary agent N-ethyl phthalimide, can solve the problem of high price and production cost Problems such as remaining high and production costs unable to meet large-scale use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 500ml stainless steel magnetically stirred autoclave, add 100g (0.68mol) phthalimide, 20ml mass ratio of 2% acetonitrile solution of potassium phthalimide, 250ml acetonitrile and 5g benzyl peroxide Acyl, closed reactor. After the air in the kettle was replaced with nitrogen, stirring was started to raise the temperature.

[0033] When the temperature rose to 50°C, ethylene gas was introduced at this time. With the introduction of ethylene, the temperature in the kettle gradually increased. Regulate the feed rate of ethylene, and control the temperature in the kettle not to exceed 100°C. When the amount of feeding ethylene reached 35g, stop feeding ethylene. Incubate at 100°C for 3 hours. After the heat preservation is over, the gas in the kettle is replaced with nitrogen, and the liquid reaction solution is poured out. Transfer to a rotary evaporator.

[0034] Acetonitrile was distilled under normal pressure, and when 170ml of distillate was evaporated, the d...

Embodiment 2

[0036] In the stainless steel magnetic stirring autoclave of 500ml, add 100g (0.68mol) phthalimide, 20ml mass ratio is the acetonitrile solution of 2% potassium phthalimide, 250ml acetonitrile and 10g ditertiary peroxide Butyl, closed reactor. After the air in the kettle was replaced with nitrogen, stirring was started to raise the temperature.

[0037] When the temperature rose to 50°C, ethylene gas was introduced at this time. With the introduction of ethylene, the temperature in the kettle gradually increased. Regulate the feeding rate of ethylene, and control the temperature in the kettle not to exceed 85°C. When the amount of feeding ethylene reached 35g, stop feeding ethylene. Incubate at 85°C for 5 hours. After the heat preservation is over, the gas in the kettle is replaced with nitrogen, and the liquid reaction solution is poured out. Transfer to a rotary evaporator.

[0038] Acetonitrile was distilled under normal pressure, and when 170ml of distillate was evap...

Embodiment 3

[0040] In a 500ml stainless steel magnetically stirred autoclave, add 100g (0.68mol) phthalimide, 30ml mass ratio of 2% acetonitrile solution of potassium phthalimide, 250ml acetone and 8g ditertiary peroxide Butyl, closed reactor. After replacing the air in the kettle with nitrogen, stirring was started.

[0041]Ethylene gas is introduced at room temperature. With the introduction of ethylene, the temperature in the kettle gradually increased. Regulate the feeding rate of ethylene, and control the temperature in the kettle not to exceed 50°C. When the amount of feeding ethylene reached 35g, stop feeding ethylene. Incubate at 50°C for 5 hours. After the heat preservation is over, the gas in the kettle is replaced with nitrogen, and the liquid reaction solution is poured out. Transfer to a rotary evaporator.

[0042] Distill acetonitrile and acetone at atmospheric pressure, and stop distillation when 190ml of distillate is evaporated. Cool to 70°C, filter potassium phtha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com