High-strength, high-toughness and good-weldability steel for mine machinery and production method of steel

A technology of steel for machinery, high strength and toughness, applied in the field of metallurgy, can solve the problems of comprehensive mechanical properties, low strength, low hardness and poor weldability of steel used for roller gear seats, and achieve guaranteed composition and mechanical properties, good weldability, The effect of improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

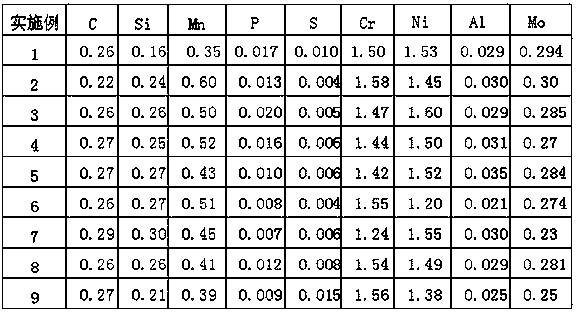

[0028] See Table 1 for the chemical composition and mass percentage of the steel for mining machinery with high strength, toughness and good weldability in this example.

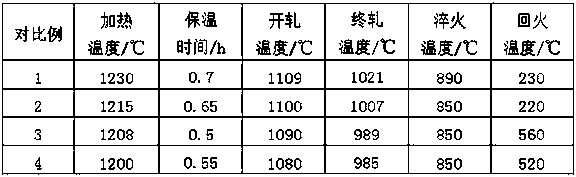

[0029] The production method of high-strength toughness and good weldability mining machinery steel in this embodiment includes smelting, continuous casting, heating, rolling, quenching and tempering treatment processes, and the specific process steps are as follows:

[0030] (1) Smelting process: 42kg / t steel of ferronickel is added to the converter, and 8kg / t of nickel plate is added to the steel ladle during the tapping process of the converter; the vacuum holding time of VD vacuum degassing treatment is 10min, and aluminum is fed after VD vacuum degassing treatment. Wire 0.3kg / t steel;

[0031] (2) Continuous casting process: the slab is cooled in a slow cooling pit, the temperature of entering the pit is 656°C, and the pit cooling time is 30h; the chemical composition and mass percentage of the slab are...

Embodiment 2

[0037] See Table 1 for the chemical composition and mass percentage of the steel for mining machinery with high strength, toughness and good weldability in this example.

[0038] The production method of high-strength toughness and good weldability mining machinery steel in this embodiment includes smelting, continuous casting, heating, rolling, quenching and tempering treatment processes, and the specific process steps are as follows:

[0039] (1) Smelting process: 42.8kg / t steel of ferronickel is added to the converter, and 8kg / t steel is added to the ladle during the tapping process of the converter; VD vacuum degassing treatment, vacuum holding time 20min, feeding after VD vacuum degassing treatment Aluminum wire 0.32kg / t steel;

[0040] (2) Continuous casting process: the slab is cooled in a slow cooling pit, the temperature of entering the pit is 632°C, and the pit cooling time is 30h; the chemical composition and mass percentage of the slab are shown in Table 1;

[004...

Embodiment 3

[0046] See Table 1 for the chemical composition and mass percentage of the steel for mining machinery with high strength, toughness and good weldability in this example.

[0047] The production method of high-strength toughness and good weldability mining machinery steel in this embodiment includes smelting, continuous casting, heating, rolling, quenching and tempering treatment processes, and the specific process steps are as follows:

[0048] (1) Smelting process: 42kg / t steel of ferronickel is added to the converter, and 12kg / t of nickel plate is added to the steel ladle during the tapping process of the converter; the vacuum holding time of VD vacuum degassing treatment is 10min, and aluminum is fed after VD vacuum degassing treatment. Wire 0.3kg / t steel;

[0049] (2) Continuous casting process: the slab is cooled in a slow cooling pit, the temperature of entering the pit is 600°C, and the pit cooling time is 25h; the chemical composition and mass percentage of the slab ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com