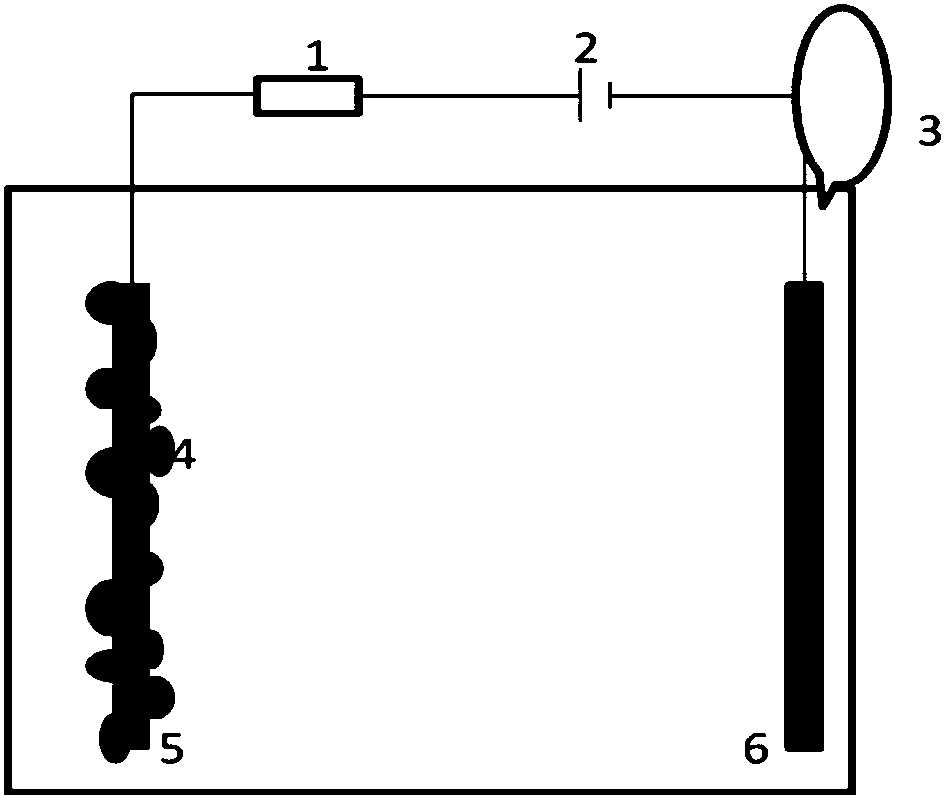

Method for treating sulfonamide wastewater and producing hydrogen synchronously by electrochemical device

A sulfonamide, electrochemical technology, applied in the direction of electrochemical biocombination treatment, chemical instruments and methods, biological water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1: Assemble three single-chamber MFCs, the size of which is a plexiglass column with a length of 4cm and a cross-sectional diameter of 3cm. The effective volume is 28ml. The anode is a circular carbon cloth with a diameter of 3cm, and the cathode is Pt / C of the same size Air cathode (painting method), the two poles are connected together with a copper wire in the external circuit and an external 1500Ω resistor is connected. Start 3 reactors in electricity production mode, mix the anaerobic wastewater from the aeration tank of the sewage treatment plant with the culture solution at a ratio of 1:1 and put it into the MFC, where the culture solution consists of: sodium salt 37.78g / L, monohydrogen phosphate Salt 15.47g / L, dihydrogen phosphate 5.84g / L, potassium salt 0.13g / L, ammonium salt 0.31g / L, chloride salt concentration 0.44g / L, acetate 1g / L, constant temperature at 30°C Run in the box, monitor the voltage changes at both ends in real time, replace the culture med...

Embodiment 2

[0024] The difference between this embodiment and Example 1 is that glucose is used instead of sodium acetate to provide nutrients for the start-up stage of microorganisms, and other steps and parameters are the same as in Example 1.

[0025] The result of the present invention is that after 48 hours, the degradation rate of sulfamethoxazole reaches about 80%, and the hydrogen production also reaches 301.1±4 μmol.

Embodiment 3

[0027] The difference between this embodiment and Example 1 is that the Pt / C air cathode is produced by rolling method, and other steps and parameters are the same as those of Example 1.

[0028] The result of the present invention is that after 48 hours, the degradation rate of sulfamethoxazole reaches more than 85%, and the hydrogen production also reaches 320.5±4 μmol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com