Metal anticorrosive coating for repairing rusted steel

A metal anti-corrosion and coating technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of noise pollution, construction difficulties, poor film-forming ability, etc., to improve anti-corrosion durability, conducive to environmental protection, and the film layer is firm and dense. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

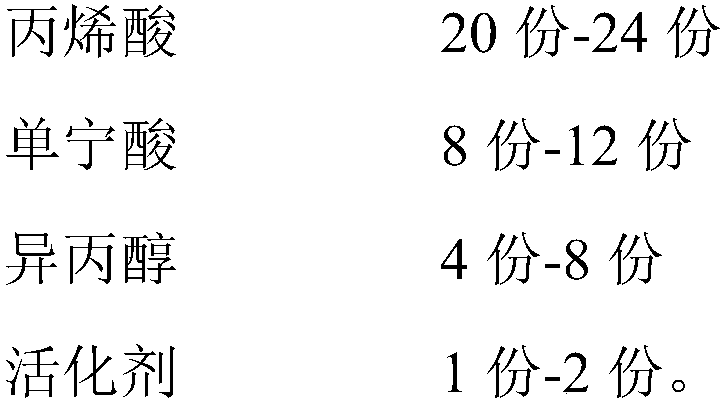

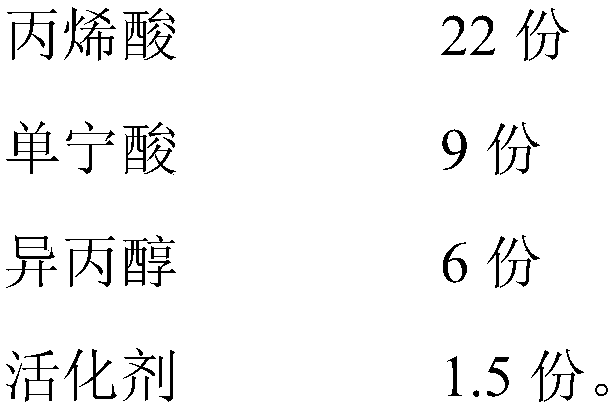

[0030] A metal anticorrosion coating for repairing corroded steel of the present embodiment comprises the following components in parts by mass:

[0031]

[0032] Above-mentioned a kind of preparation method for repairing the metal anticorrosion paint of corroded steel, comprises the following steps:

[0033] 1) In parts by mass, weigh 22 parts of acrylic acid, 9 parts of tannic acid, 6 parts of isopropanol and 1.5 parts of activator citric acid;

[0034] 2) Add ethanol, tannic acid and water into the reactor, mix and dissolve completely, add isopropanol, activator and water respectively, then add acrylic acid, film-forming aid, and defoamer, and continue to stir for 20 minutes -30min, make described metal anticorrosion paint.

Embodiment 2

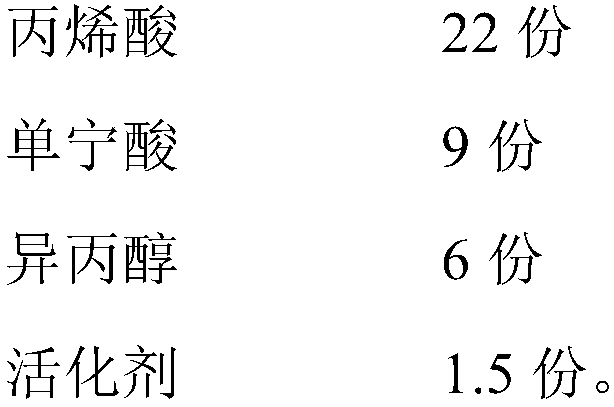

[0036] A metal anticorrosion coating for repairing corroded steel of the present embodiment comprises the following components in parts by mass:

[0037]

[0038]

[0039] Above-mentioned a kind of preparation method for repairing the metal anticorrosion paint of corroded steel, comprises the following steps:

[0040] 1) In parts by mass, weigh 20 parts of acrylic acid, 8 parts of tannic acid, 4 parts of isopropanol and 1 part of activator citric acid;

[0041] 2) Add ethanol, tannic acid and water into the reactor, mix and dissolve completely, add isopropanol, activator and water respectively, then add acrylic acid, film-forming aid, and add defoamer and organic film aid agent, and continue to stir for 20min-30min to make the metal anti-corrosion coating.

Embodiment 3

[0043] A metal anticorrosion coating for repairing corroded steel of the present embodiment comprises the following components in parts by mass:

[0044]

[0045] Above-mentioned a kind of preparation method for repairing the metal anticorrosion paint of corroded steel, comprises the following steps:

[0046] 1) In parts by mass, weigh 24 parts of acrylic acid, 12 parts of tannic acid, 8 parts of isopropanol and 2 parts of activator citric acid;

[0047] 2) Add ethanol, tannic acid and water into the reactor, mix and dissolve completely, add isopropanol, activator and water respectively, then add acrylic acid, film-forming aid, defoamer, and silicone oil , and vacuum bubbles, and continue to stir for 20min-30min to prepare the metal anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com