Oil well cement high-temperature retarder microcapsule and preparation method thereof

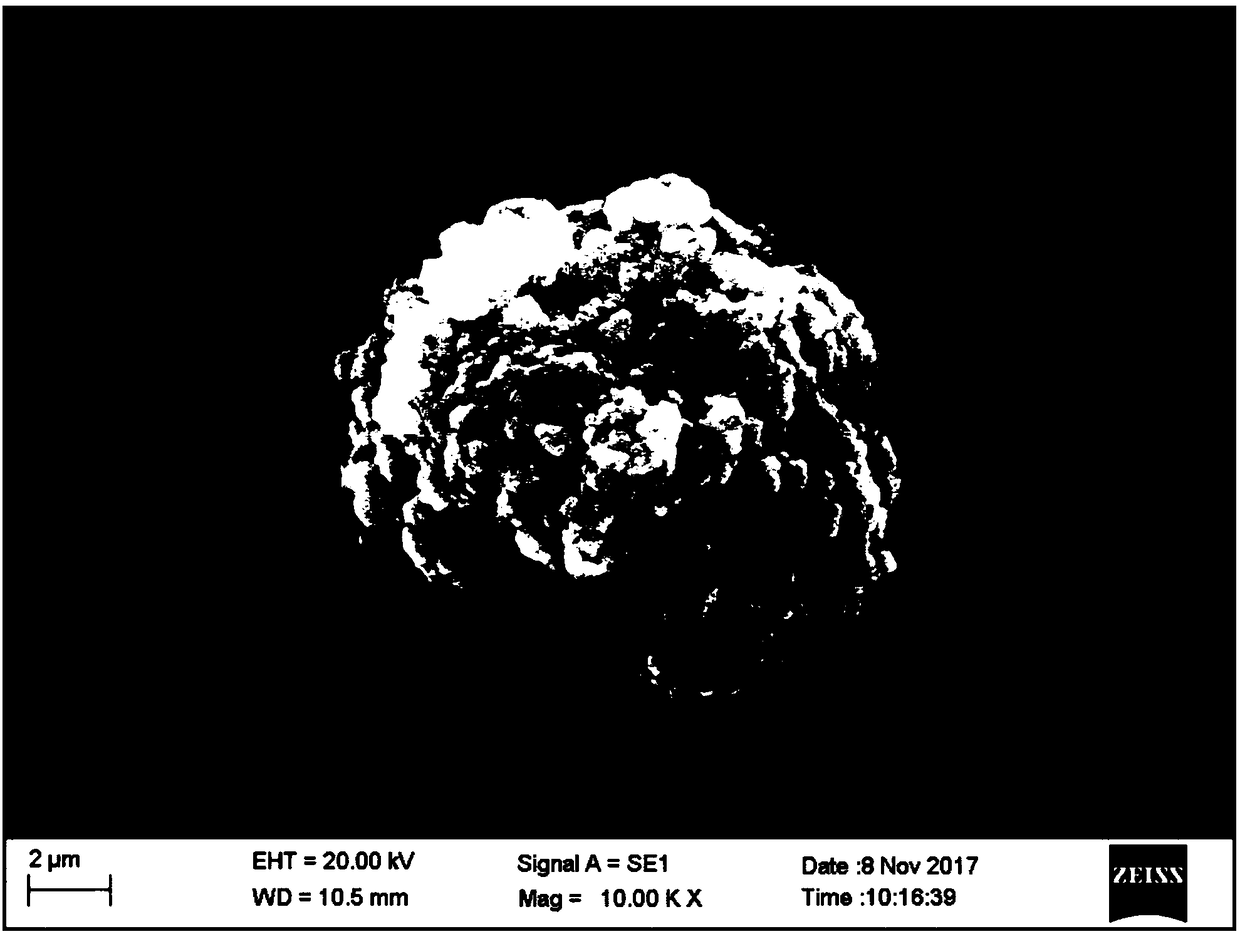

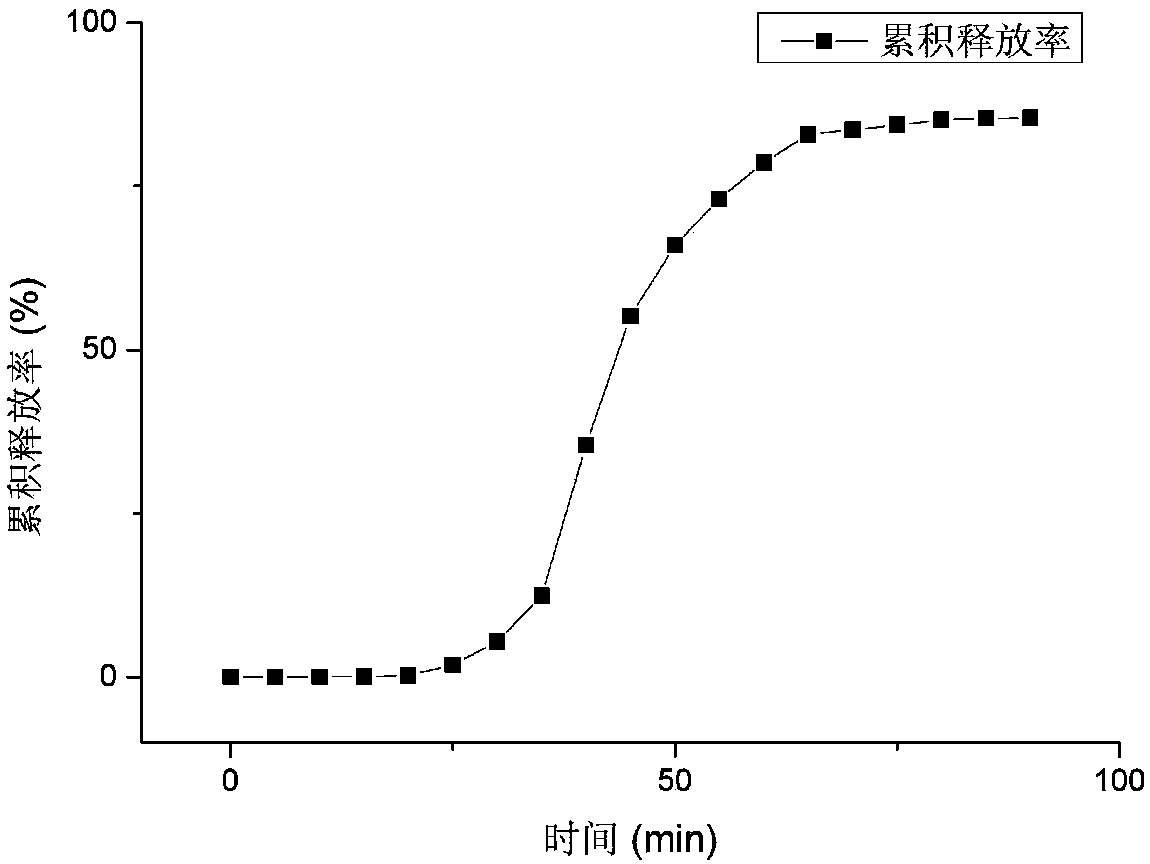

An oil well cement and retarder technology, which is applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of ultra-retardation of cement slurry, single performance of cement retarder, and insufficient cross-temperature zone width, etc. The effect of small diameter, wide application range and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

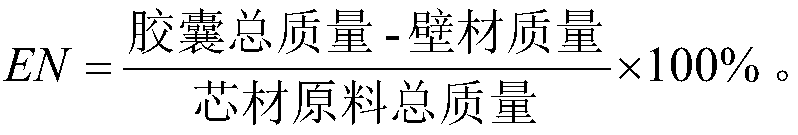

[0034] The preparation method of oil well cement high temperature retarder microcapsules is as follows:

[0035] Step S1, weigh 60 parts of high-temperature retarder SN-3 and dissolve in 50 parts of deionized water to dissolve completely, then add 0.5 parts of Span 80, add the mixed solution into the container, adopt mechanical emulsification method, control the speed of 10000r / min Stir and pre-emulsify at room temperature for 10 minutes;

[0036] Step S2, take by weighing 10 parts of reactive diluent (5 parts of tripropylene glycol diacrylate TPGDA and ditrimethylolpropane tetraacrylate DTMPTA each), 20 parts of polyurethane acrylate CN972, 2 parts of photoinitiator (photoinitiated Each 1 part of photoinitiator 1173 and photoinitiator 184), add in the reaction container; Wherein, photoinitiator 1173 refers to α-hydroxyisobutyrophenone, and photoinitiator 184 refers to 1-hydroxycyclohexyl phenyl ketone;

[0037] Step S3, taking 100 parts of deionized water and 1 part of Tween...

Embodiment 2

[0040] The preparation method of oil well cement high temperature retarder microcapsules is as follows:

[0041] Step S1, weigh 50 parts of lignosulfonate and dissolve in 50 parts of deionized water to dissolve completely, then add 1 part of Span 80, add the mixed solution into the container, adopt mechanical emulsification method, control the rotation speed of 10000r / min to stir, Pre-emulsify at room temperature for 10 minutes;

[0042] Step S2, weighing 5 parts of reactive diluent alkyl acrylate, 30 parts of polyester acrylic resin, 3 parts of photoinitiator 2959 (2-hydroxy-4'-(2-hydroxyethoxy)-2-methylbenzene acetone), add in the reaction vessel;

[0043] Step S3, taking 100 parts of deionized water and 1.5 parts of Tween 80 into the reaction vessel, stirring mechanically, controlling the rotation speed to 600r / min, stirring for 5 minutes, then adding the emulsion prepared in step S1 into the reaction vessel, and continuing to stir for 15 minutes;

[0044] Step S4, feed n...

Embodiment 3

[0046] The preparation method of oil well cement high temperature retarder microcapsules is as follows:

[0047] Step S1, take 55 parts of high-temperature retarder boric acid and dissolve in 50 parts of deionized water to dissolve completely, then add 1.5 parts of Span 80, add the mixed solution into the container, use mechanical emulsification method, control the speed of 10000r / min to stir, Pre-emulsify at room temperature for 15 minutes;

[0048] Step S2, weighing 10 parts of active diluent (3 parts of dimethyl dithiophosphate DMPTA, 3 parts of pentaerythritol triacrylate PETA, 4 parts of diphenylphosphoryl azide DPPA), 20 parts of polyurethane acrylate CN972, 2 parts Part photoinitiator 1173 (alpha-hydroxyisobutyrophenone), adds in the reaction vessel;

[0049] Step S3, take 100 parts of deionized water and 0.5 parts of Tween 80 into the reaction vessel, stir mechanically, control the rotation speed to 600r / min, stir for 10 minutes, then add the emulsion prepared in step S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com