Enzyme composition for improving constipation and preparation method thereof

A technology for improving constipation and composition, applied in the field of enzyme composition for improving constipation and its preparation, can solve problems such as liver function damage, aggravation of cardiovascular disease, increase of toxic metabolites, etc., so as to increase gastrointestinal motility and clean the intestines well. , the effect of increasing satiety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

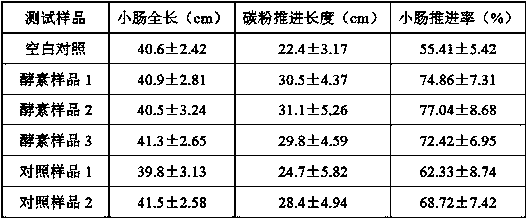

Examples

Embodiment 1

[0019] 1) Immerse 100g artichoke in 5% saline solution and boil, then add 150g figs, 100g feijoa, 80g gooseberry, 60g wheat seedlings, continue cooking for 2 minutes under stirring condition, remove and drain Moisture, pre-treated materials;

[0020] 2) Pour the pretreated material and 80g of psyllium seed husk powder into the fermentation tank, add 2.94g of compound fermentation bacteria, mix well, and ferment anaerobically at 35°C for 5 days;

[0021] 3) After the fermentation, add 147 mg of pectinase into the fermenter, stir and mix intermittently for 1 hour by stirring for 25 minutes and pausing for 5 minutes, then filter, and freeze-dry the filtrate;

[0022] 4) Mix the freeze-dried powder obtained in step 3) with 100g of apple stem cell freeze-dried powder and 140g of fructo-oligosaccharide powder to prepare enzyme sample 1.

Embodiment 2

[0024] 1) Soak 90g of artichokes in 6% saline solution and boil, then pour in 120g of figs, 150g of feijoa, 60g of gooseberries, and 70g of wheat seedlings, continue cooking for 2 minutes under stirring conditions, remove and drain Moisture, pre-treated materials;

[0025] 2) Pour the pretreated material and 70g of psyllium seed husk powder into the fermentation tank, add 3.43g of compound fermentation bacteria, mix well, and ferment anaerobically at 36°C for 4 days;

[0026] 3) After the fermentation, add 196 mg of pectinase into the fermenter, stir and mix intermittently for 1 hour by stirring for 25 minutes and pausing for 5 minutes, then filter, and freeze-dry the filtrate;

[0027] 4) Mix the freeze-dried powder obtained in step 3) with 110g of apple stem cell freeze-dried powder and 140g of fructo-oligosaccharide powder to prepare enzyme sample 2.

Embodiment 3

[0029] 1) Immerse 80g of artichokes in 8% saline solution and boil, then pour in 100g of figs, 120g of feijoa, 100g of gooseberries, and 80g of wheat seedlings, continue cooking for 3 minutes under stirring conditions, remove and drain Moisture, pre-treated materials;

[0030] 2) Pour the pretreated material and 50g of psyllium seed husk powder into the fermentation tank, add 3.84g of compound fermentation bacteria, mix well, and ferment anaerobically at 37°C for 3 days;

[0031] 3) After the fermentation, add 240 mg of pectinase into the fermenter, stir and mix intermittently for 25 minutes and pause for 5 minutes, then filter for 2 hours, and freeze-dry the filtrate;

[0032] 4) Mix the freeze-dried powder obtained in step 3) with 120g of apple stem cell freeze-dried powder and 160g of fructo-oligosaccharide powder to prepare enzyme sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com