Preparation method of high-manganese non-magnetic steel powder

A technology of non-magnetic steel and high manganese, applied in the field of powder metallurgy, can solve the problems of poor powder compactability and formability, low green strength, poor density and toughness of powder metallurgy products, and achieve the effect of improving compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

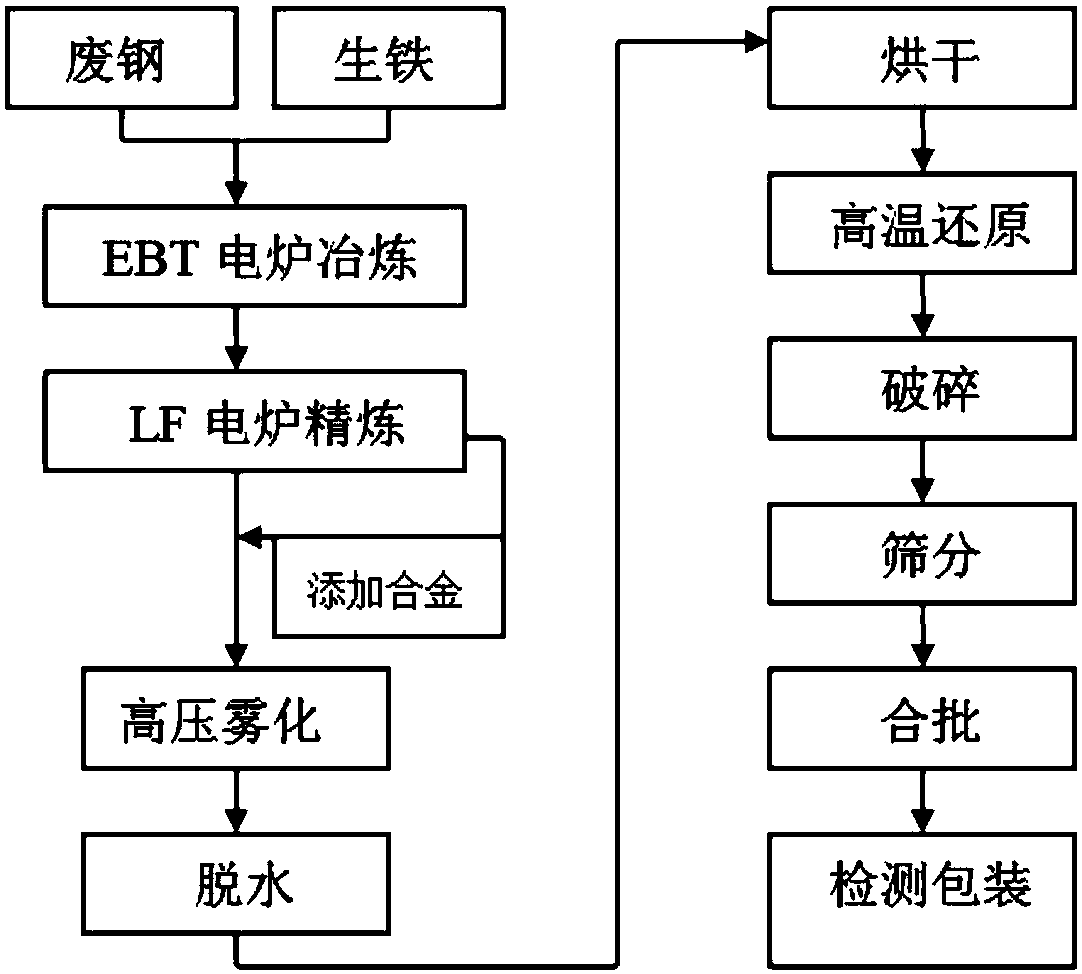

[0027] In one embodiment of the present invention, the preparation method of the high manganese non-magnetic steel powder provided comprises the steps:

[0028] (1) Select high-quality common carbon steel scrap and pig iron for steelmaking, and make ingredients according to the ratio of 1:1;

[0029] (2) Dosing twice in succession, adding coke accounting for 1.5-2% of the total weight of the ingredients when adding the second batch, smelting in EBT electric furnace, refining in LF electric furnace after tapping, adding metal manganese and ferrosilicon in three times , carry out pre-alloying treatment, deoxidation treatment, adjust the composition and temperature after tapping, and prepare for atomization;

[0030] (3) Atomize spraying with 10-12MPa water pressure using annular slit nozzle, dehydration treatment by hydrocyclone and disc-type inner filter dehydrator, and indirect drying with gas to obtain primary powder;

[0031] (4) Use a fine reduction furnace to perform high...

Embodiment 1

[0050] The composition of common carbon scrap steel is: Si≤0.20%, Mn≤0.50%, P≤0.04%, S≤0.04%, Cr+Ni+Cu+Mo≤0.20%; the composition of steelmaking pig iron is: Si≤0.45% , Mn≤0.40%, P≤0.07%, S≤0.07%, Cr+Ni+Cu+Mo≤0.20%. According to scrap steel: pig iron = 1:1 ratio (weight ratio), the ingredients are added to the EBT electric furnace as raw materials, and about 300Kg of coke is added to the bottom of the secondary material (the amount of coke added is 1.5-2% of the total weight of the raw materials). Coke requirements: lumpiness Diameter: 3-5cm, C 固 ≥80%, S≤0.50%. Detection before tapping: temperature: 1645°C, C: 0.15%, Si: 0.04%, Mn: 0.12%, P: 0.010%, S: 0.030%, rapid tapping (prohibit oxidation slag from flowing into the ladle).

[0051] Use the tapping flat car to send to the refining station, use the LF refining furnace to refine, use argon gas to stir for 2 minutes before power transmission and refining; after the power transmission and refining start, manually add an appro...

Embodiment 2

[0055] The composition of common carbon scrap steel is: Si≤0.20%, Mn≤0.50%, P≤0.04%, S≤0.04%, Cr+Ni+Cu+Mo≤0.20%, and the composition of steelmaking pig iron is: Si≤0.45% , Mn≤0.40%, P≤0.07%, S≤0.07%, Cr+Ni+Cu+Mo≤0.20%. According to the ratio of scrap steel: pig iron = 1:1, the ingredients are fed into the furnace, and the secondary material is mixed with 260Kg coke blocks. Coke requirements: block diameter: 3-5cm, C 固 ≥80%, S≤0.50%. Detection before tapping: temperature: 1650°C, C: 0.19%, Si: 0.03%, Mn: 0.10%, P: 0.008%, S: 0.032%, fast tapping (prohibit oxidation slag from flowing into the ladle), use tapping flat The car is sent to the refining station. Before power transmission and refining, use argon gas to stir for 2 minutes; after power transmission and refining, manually add synthetic slag, add 20Kg of ferrosilicon as deoxidizer, use quicklime as desulfurizer, white slag refining time is not After less than 10 minutes, the temperature was raised to 1650°C, and 1t of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com