Method for preparing graphene by recycling graphite cathode material from power batteries

A technology of power battery and graphite negative electrode is applied in the field of preparing graphene by recycling graphite negative electrode material from power battery. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

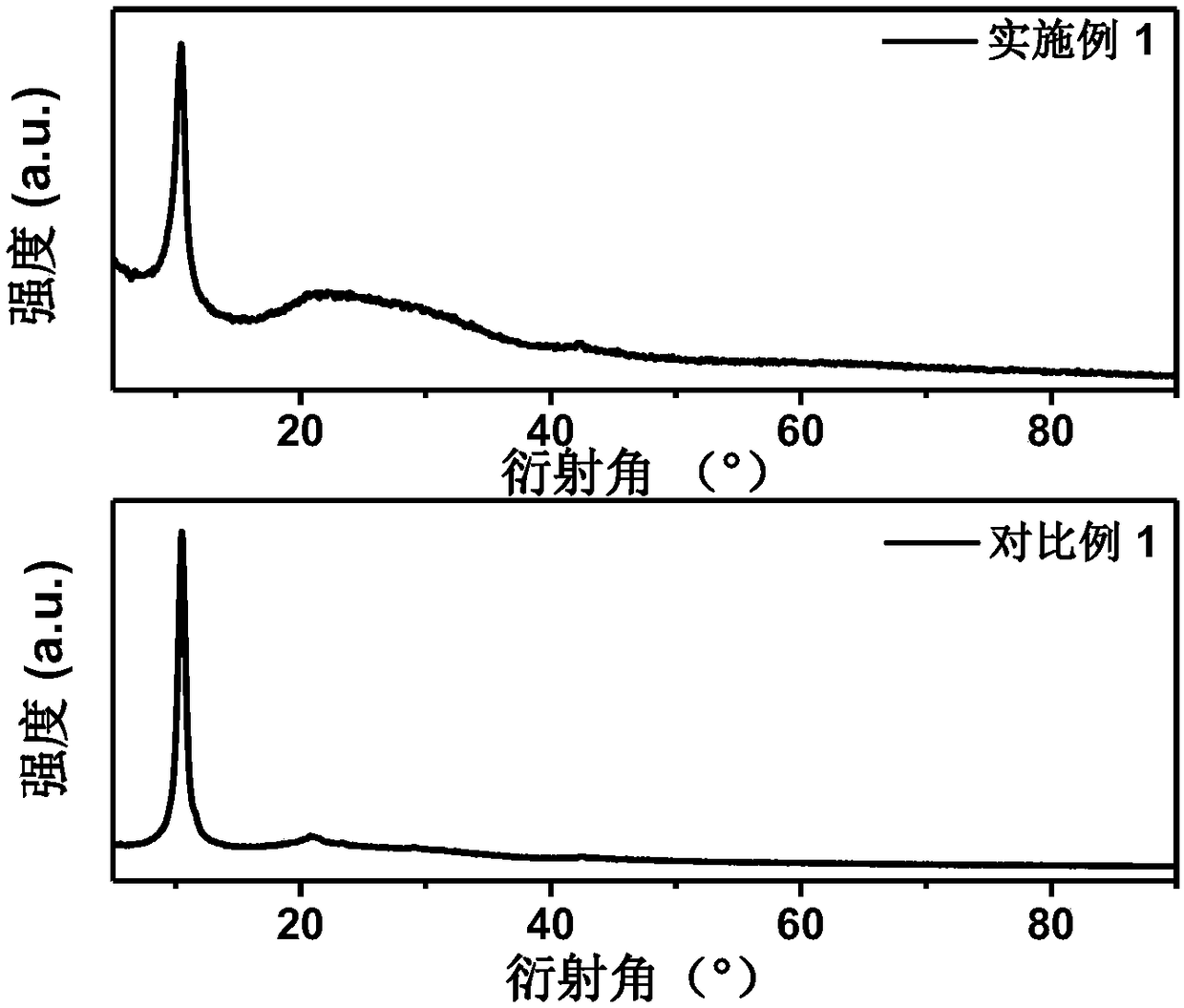

Embodiment 1

[0037] A method for preparing graphene by reclaiming graphite negative electrode materials from power batteries, comprising the steps of:

[0038] (1) Break the shell of the commercial waste power battery, peel off the graphite negative electrode sheet of the battery, and cut the electrode sheet into strips of 1*5cm.

[0039] (2) Put the treated negative electrode fragments in a clean large beaker, add deionized water at 25°C according to the ratio of the mass of the negative electrode piece to the mass of deionized water (1:20) for soaking for 1 min, and the negative electrode active material is immediately mixed with copper Foil separation, take out the copper foil from which the active material has been separated.

[0040] (3) Stir for 2 h at a stirring rate of 600 r / min under the action of a magnet, and after standing still for 12 h, pour the upper layer of turbid liquid, and add water again to make the volume of the solution equal to the original volume.

[0041] (4) Rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com