Compound microbial degradation agent for organic pollutants and preparation method of compound microbial degradation agent

A technology of organic pollutants and composite microorganisms, which is applied to the degradation of organic waste by biological materials and/or photocatalytic materials, and the treatment of organic pollutants, and can solve the problems of limited use of photocatalysts and limited application environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 prepares nano titanium dioxide

[0028]First, 30mL of water and 120mL of ethanol were mixed in a volume ratio of 1:4, and acid or alkali was added to adjust the pH of the solution to obtain a solution as a reaction medium, and then 18mL of the precursor tetra-n-butyl titanate (TBT) was mixed with ethanol, As a reaction precursor, add it dropwise to a mixed solvent of water and ethanol at 75°C, and continue to react at 75°C for 24 hours after the dropwise addition is completed, and perform high-speed centrifugation on the obtained suspension, wash with water and ethanol, and dry Afterwards, nano-titanium dioxide powder is obtained.

Embodiment 2

[0029] Embodiment 2 prepares bacterial powder

[0030] 1. Preparation of Bacillus bacteria powder

[0031] a. Slant culture: inoculate the original strains of Bacillus subtilis and Bacillus megaterium on the slant medium under sterile conditions, and cultivate them at 30±2°C for 24 to 36 hours;

[0032] b. Shaker culture: Inoculate the strains cultured in step a into the seed medium under sterile conditions, and culture on a shaker at 160-180r / min for 12-18 hours at pH 7.0-7.5 and 30°C ;

[0033] c. Fermentation tank culture: Inoculate the strains cultivated in step b into the liquid fermentation medium under sterile conditions respectively, at pH 7.0-8.0, tank pressure 0.5kg / cm 2 , 30 DEG C, ventilation rate 1:0.8~1.1 under the conditions, after cultivating for 48~72 hours, when 80% of the bacteria become spores, put into the tank to obtain the fermentation liquid;

[0034] d. After concentrating the fermented liquid obtained in step c, mix and dry it with carrier chaff po...

Embodiment 3

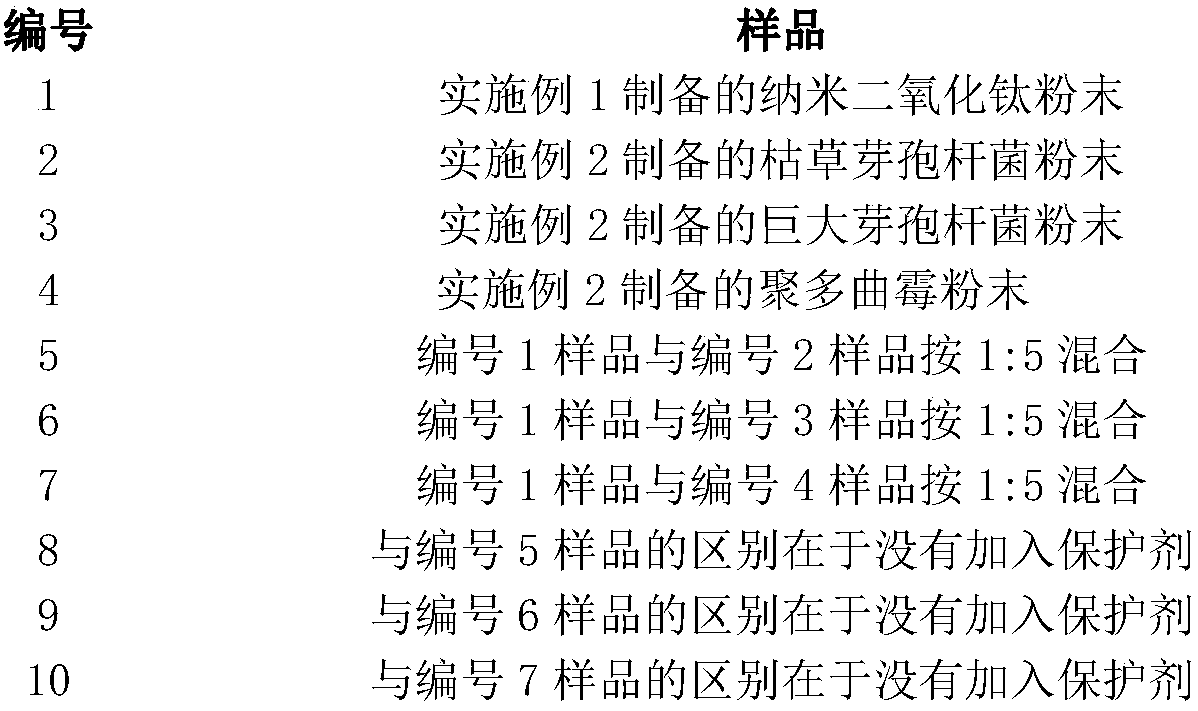

[0043] Embodiment 3 prepares organic pollutant composite microbial degradation agent

[0044] Weigh bacterial powder, vegetable oil, BHA according to parts by weight, and slowly mix them in a blender evenly to obtain treated bacterial powder or spore powder; mix other auxiliary materials to obtain adjuvant mixture; prepare according to the weight ratio of Example 1 The obtained nano-titanium dioxide is mixed with the bacteria powder, then the auxiliary agent mixture is added, stirred evenly in a mixer, and then dried, screened and packaged to obtain a composite microbial degradation agent for organic pollutants.

[0045] Concrete preparation obtains following product (characterize each component consumption with weight percentage):

[0046] Product 1: Bacillus subtilis powder (preservation number is CGMCC NO.1.9083, about 100 million cfu / g) 5%, nano-titanium dioxide 30%, BHA 1%, grape seed oil 9%, glucose 15%, light calcium carbonate 20%, sodium dodecylbenzene sulfonate 5%, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com