Concrete material for pavement slabs and preparation method thereof

A technology for concrete and pavement panels, applied in the field of pavement panels, can solve the problems of restricting the development and application of concrete pavement panels, poor water permeability and adhesion resistance, and affecting road safety hidden dangers, so as to improve the urban road environment and city appearance, and enhance the compression resistance. Strength and water permeability, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A concrete material for road slabs, weighing the following raw materials: 60kg of composite cement, 1kg of expansion agent, 1kg of early strength agent, 1kg of water retention agent, 1kg of dispersant, 3kg of clay grade mica, 4kg of high silicon iron tailings, 3kg of carbide slag, Porous zirconia ceramics 2kg, rectorite 3kg, quartz sandstone 3kg, serpentine asbestos fiber 1kg, sodium polyacrylate 1kg, barium chloride 0.8kg.

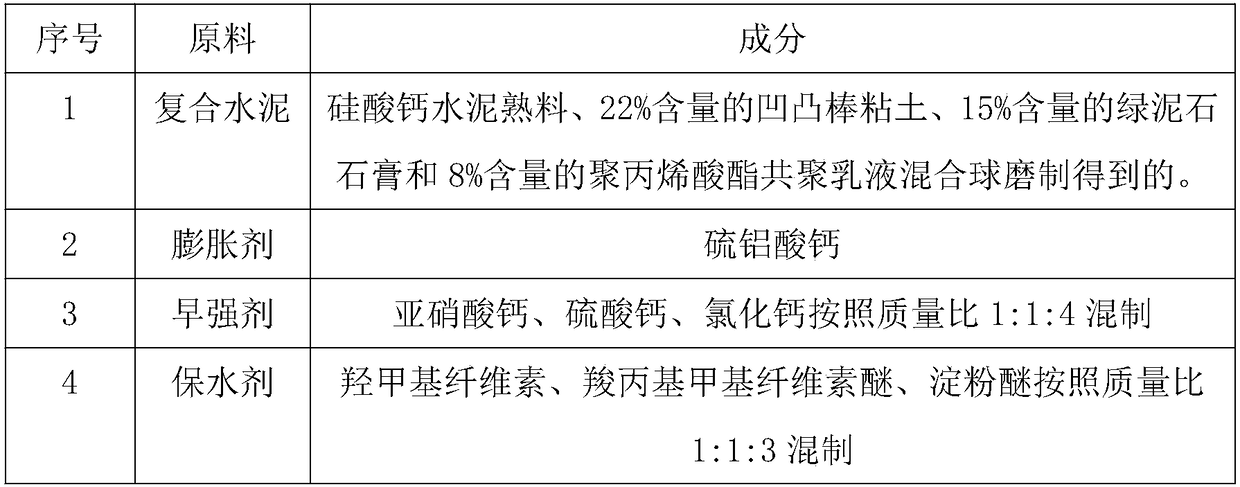

[0041] The preparation and selection of the above-mentioned part of raw materials are shown in Table 1 below:

[0042] Table 1

[0043]

[0044]

[0045] The preparation method of above-mentioned pavement concrete material is as follows:

[0046] (1) Put clay-grade mica, high-silicon iron tailings, calcium carbide slag, porous zirconia ceramics, rectorite, quartz sandstone, and serpentine asbestos fibers into the ball mill jar first. The magic ball is made of corundum, and the ball-to-material ratio is 2:1, the mass ratio of large balls to ...

Embodiment 2

[0049] A concrete material for road slabs, weighing the following raw materials: 65kg of composite cement, 1.25kg of expansion agent, 1.5kg of early strength agent, 1.5kg of water retention agent, 1.25kg of dispersant, 4kg of clay-grade mica, 5kg of high-silicon iron tailings, Carbide slag 4kg, porous zirconia ceramics 2.5kg, rectorite 4kg, quartz sandstone 4kg, serpentine asbestos fiber 1.5kg, sodium polyacrylate 1.1kg, barium chloride 0.9kg.

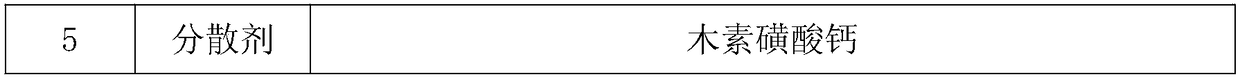

[0050] The preparation and selection of the above-mentioned part of raw materials are shown in Table 2 below:

[0051] Table 2

[0052]

[0053] The preparation method of above-mentioned pavement concrete material is as follows:

[0054] (1) Put clay-grade mica, high-silicon iron tailings, calcium carbide slag, porous zirconia ceramics, rectorite, quartz sandstone, and serpentine asbestos fibers into the ball mill jar first. The magic ball is made of corundum, and the ball-to-material ratio is 2:1, the mass ratio of large balls to...

Embodiment 3

[0057] A concrete material for road slabs, weighing the following raw materials: 70kg of composite cement, 1.5kg of expansion agent, 2kg of early strength agent, 2kg of water retention agent, 1.5kg of dispersant, 5kg of clay-grade mica, 6kg of high-silicon iron tailings, and calcium carbide slag 5kg, porous zirconia ceramics 3kg, rectorite 5kg, quartz sandstone 5kg, serpentine asbestos fiber 2kg, sodium polyacrylate 1.2kg, barium chloride 1kg.

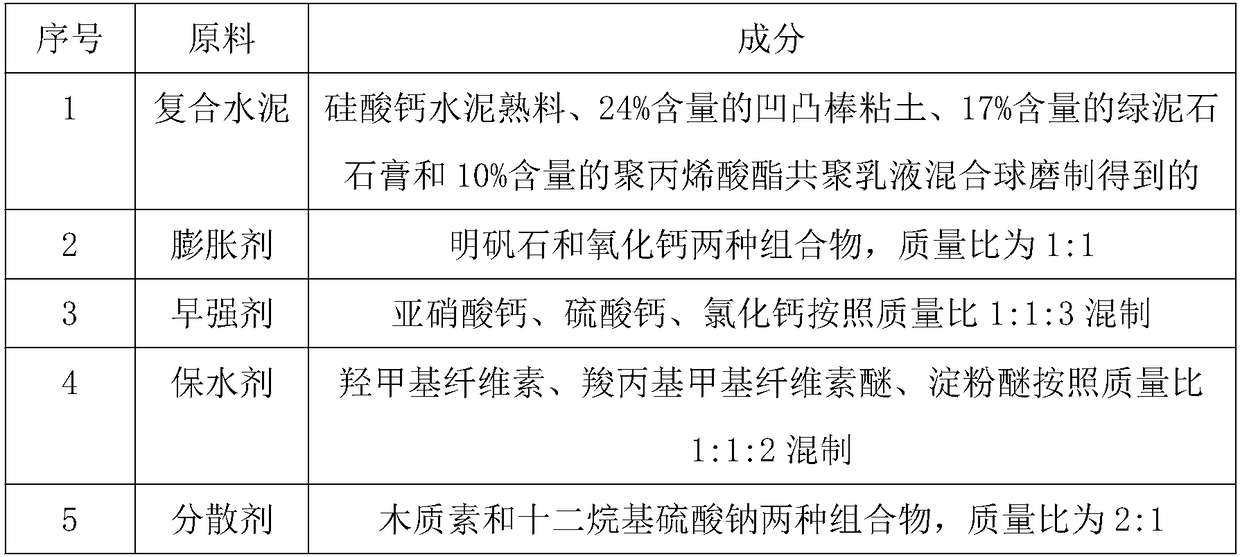

[0058] The preparation and selection of the above-mentioned part of raw materials are shown in Table 3 below:

[0059] table 3

[0060]

[0061] The preparation method of above-mentioned pavement concrete material is as follows:

[0062](1) Put clay-grade mica, high-silicon iron tailings, calcium carbide slag, porous zirconia ceramics, rectorite, quartz sandstone, and serpentine asbestos fibers into the ball mill jar first. The magic ball is made of corundum, and the ball-to-material ratio is 2:1, the mass ratio of large balls to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability coefficient | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com