Preparation method of ceramic permeable brick suitable for low temperature fast firing

A technology of permeable bricks and ceramics, applied in the field of architectural ceramics, which can solve the problems of limited use of waste ceramics, increased demand for clay minerals, complex formulas and processes, etc., and achieves low technical difficulty in adjustment, great advantages in industrialization, and short firing cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

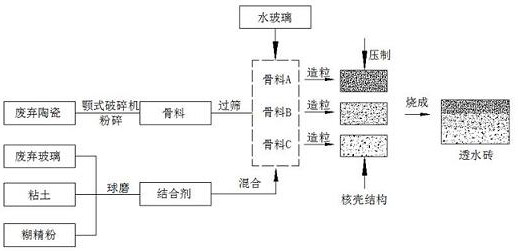

[0038] Embodiment 1 of the present invention provides a method for preparing a ceramic permeable brick suitable for low-temperature fast-firing, and the preparation method is realized through the following steps:

[0039] ① Use a jaw crusher to crush waste ceramics into particles with a diameter of about 2-5 mm, and sieve them into 2-3 mm, 3-4 mm, and 4-5 mm, respectively A, B, and C. Granules for spare.

[0040] ② Use a drum-type ball mill to mix flat glass and kaolin at a mass ratio of 5:3, add 1% dextrin powder, perform dry powder ball milling, and take it out to obtain a binder for use.

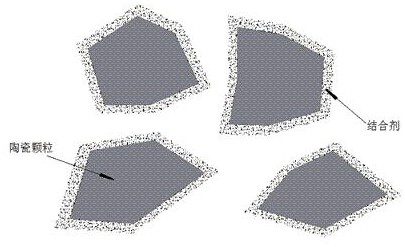

[0041] ③Put the ceramic granules obtained in the step ① into a mixer, and add 8% water glass solutions with a concentration of 4%, 3%, and 2% respectively in the aggregates from large to small. After mixing evenly, add 20% of the binder in step ②, and granulate so that the binder is evenly wrapped on the surface of the broken porcelain particles to form a core-shell structure, thereby ob...

Embodiment 2

[0046] Embodiment 2 of the present invention provides a method for preparing ceramic permeable bricks suitable for low-temperature fast-firing, and the preparation method is realized through the following steps:

[0047] ① Use a jaw crusher to crush waste porcelain plates and dishes into particles with a diameter of about 2-5mm, and sieve them into 2-3mm, 3-4mm, 4-5mm, respectively A, B, and C Granules for spare.

[0048] ②Use a roller ball mill to mix flat glass and kaolin at a mass ratio of 5:2, add 1.5% dextrin powder, perform dry powder ball milling, and take it out to obtain a binder for use.

[0049] ③Put the ceramic particles obtained in the step ① into a mixer, and add 7% water glass solutions with a concentration of 4%, 3%, and 2% respectively in the aggregates from large to small. After mixing evenly, add 15% of the binder in step ②, and granulate so that the binder is evenly wrapped on the surface of the broken porcelain particles to form a core-shell structure, th...

Embodiment 3

[0054] Embodiment 3 of the present invention provides a method for preparing ceramic permeable bricks suitable for low-temperature fast-firing, and the preparation method is realized through the following steps:

[0055] ① Use a jaw crusher to crush waste porcelain plates and dishes into particles with a diameter of about 2-5mm, and sieve them into 2-3mm, 3-4mm, 4-5mm, respectively A, B, and C Granules for spare.

[0056] ② Use a drum-type ball mill to mix flat glass and kaolin at a mass ratio of 5:2, add 1% dextrin powder, perform dry powder ball milling, and take it out to obtain a binder for use.

[0057] ③Put the ceramic granules obtained in the step ① into a mixer, and add 8% water glass solutions with a concentration of 4%, 3%, and 2% respectively in the aggregates from large to small. After mixing evenly, add 20% of the binder in step ②, and granulate so that the binder is evenly wrapped on the surface of the broken porcelain particles to form a core-shell structure, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com