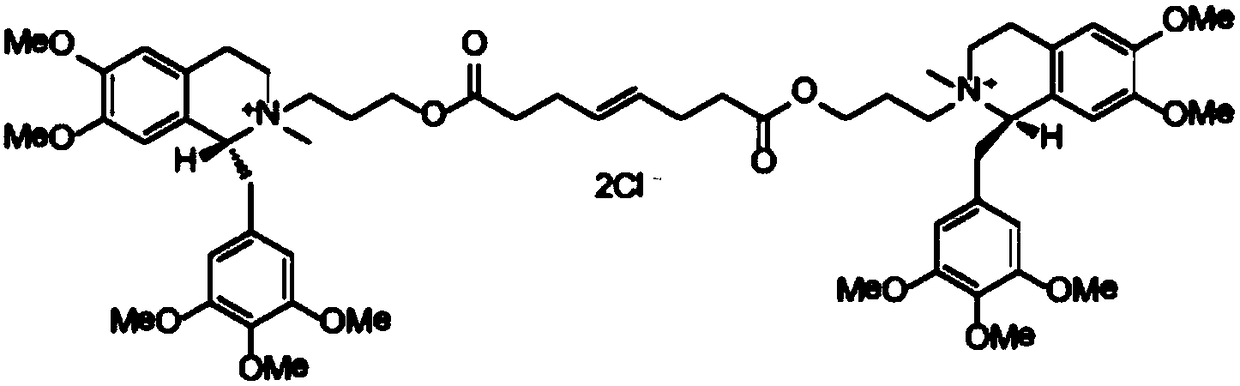

Preparation method for mivacurium chloride

A technology of mivacurium chloride and mivacurium chloride dihydrochloride, applied in the field of biomedicine, can solve problems such as small side effects, histamine release, and cardiovascular system damage, and achieve small changes in impurity content, low impurity content, The effect of high chiral purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

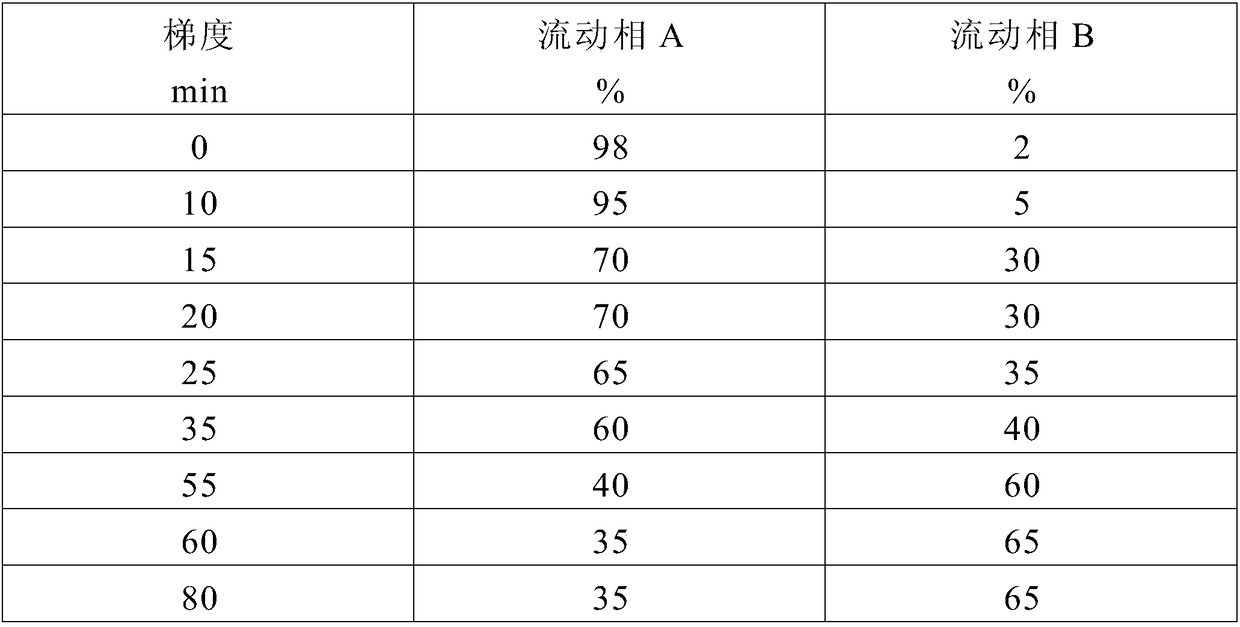

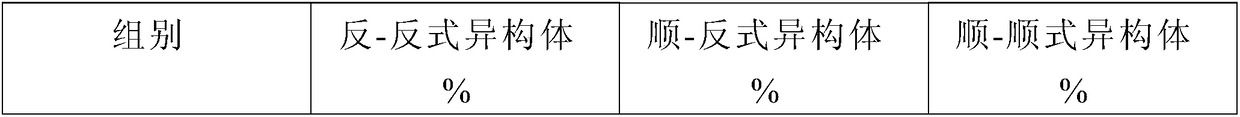

Examples

Embodiment 1

[0028] (1) Get 10g of ricecuronium chloride crude product and add in 500ml tetrahydrofuran, add dropwise hydrochloric acid solution (concentration is 36%) to solid dissolution under stirring, evaporate to dryness under reduced pressure, obtain ricecuronium chloride dihydrochloride crude product 9.79g;

[0029] (2) Add 9.79 g of the crude product of mivacuronium chloride dihydrochloride into 500 ml of ethyl acetate, stir at 30° C. for 2 hours, and filter with suction to obtain 9.12 g of mivacuronium chloride dihydrochloride;

[0030] (3) 9.12g of prepared ricecuronium chloride dihydrochloride is added in 100ml ethanol, and 30ml of propylene oxide is added, and the solid is precipitated under stirring, suction filtered, and dried to obtain 7.03g ricecuronium chloride; total yield 70.3 %.

Embodiment 2

[0032] (1) Get 10g of ricecuronium chloride crude product and add in 1000ml of n-hexanol, add dropwise hydrochloric acid solution (concentration is 36%) to solid dissolution under stirring, evaporate to dryness under reduced pressure, get ricecuronium chloride dihydrochloride crude product 9.71g;

[0033] (2) Add 9.71 g of the crude product of mivacuronium chloride dihydrochloride into 600 ml of ethyl acetate, stir at 30° C. for 2 hours, and filter with suction to obtain 9.01 g of mivacuronium chloride dihydrochloride;

[0034] (3) 9.01g of prepared ricecuronium chloride dihydrochloride is added in 100ml ethanol, and 30ml of propylene oxide is added, and the solid is precipitated under stirring, suction filtered, and dried to obtain 7.1g ricecuronium chloride; total yield 71.0 %.

Embodiment 3

[0036] (1) Get 10g of ricecuronium chloride crude product and add in the mixture that 100ml tetrahydrofuran and 500ml n-hexanol form, add dropwise hydrochloric acid solution (concentration is 36%) to solid dissolving under stirring, evaporate to dryness under reduced pressure, get ricecuronium chloride disalt Salt crude product 9.89g;

[0037] (2) Add 9.89 g of the crude product of mivacuronium chloride dihydrochloride into 1000 ml of ethyl acetate, stir at 30° C. for 2 hours, and filter with suction to obtain 9.29 g of mivacuronium chloride dihydrochloride;

[0038] (3) 9.29g of prepared ricecuronium chloride dihydrochloride is added in 100ml ethanol, 30ml of propylene oxide is added, and the solid is precipitated under stirring, suction filtered, and dried to obtain 7.62g ricecuronium chloride; total yield 76.2 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com