Strong-acid-and-alkali-resistant composite pipe made of glass fiber reinforced plastic regenerated material and production method of strong-acid-and-alkali-resistant composite pipe

A technology of glass fiber reinforced plastics and strong acid resistance, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems that affect the use of concrete pipes, shorten the working life, and the interface is easy to leak, so as to reduce the cost of water delivery and the maintenance of pipelines, increase Enterprise benefit, the effect of smooth inner surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

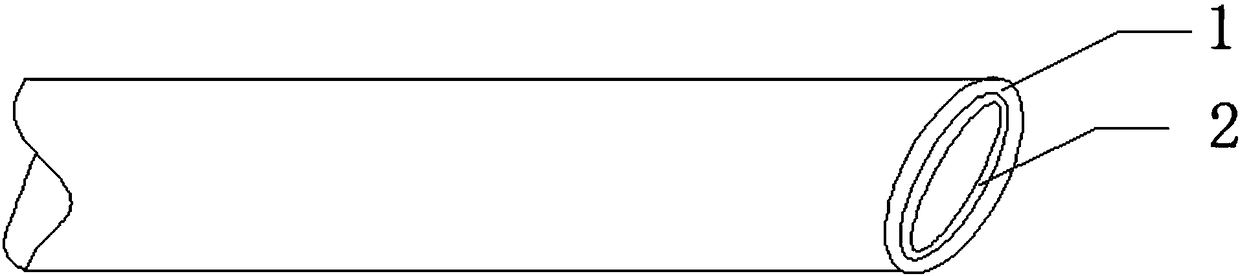

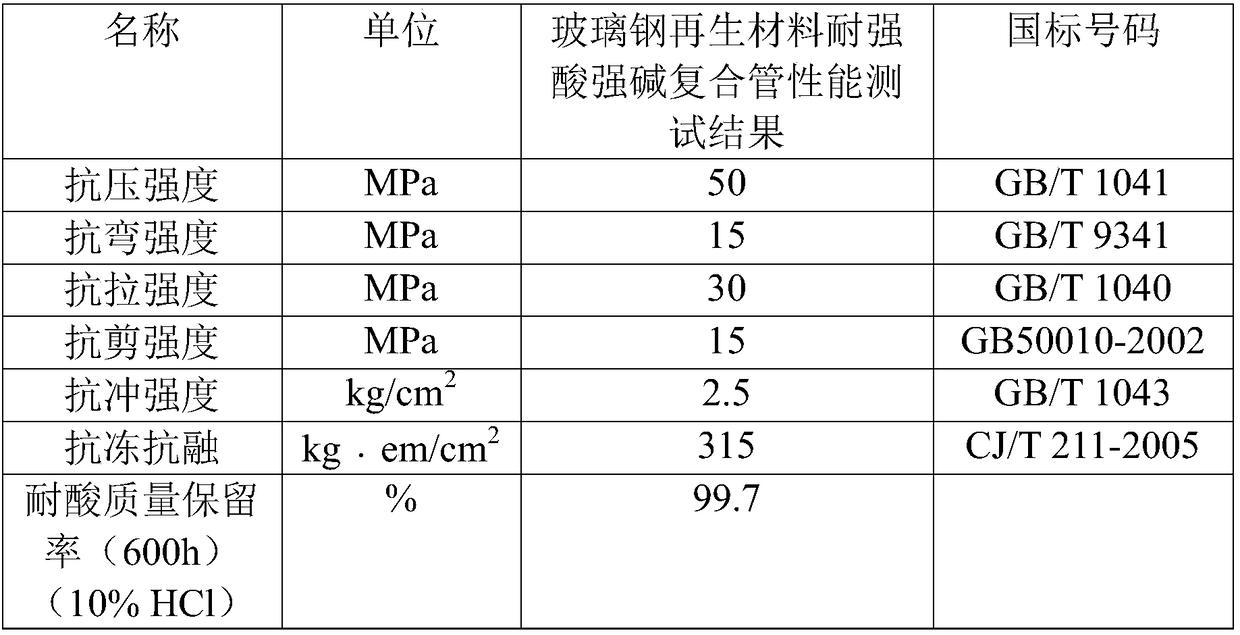

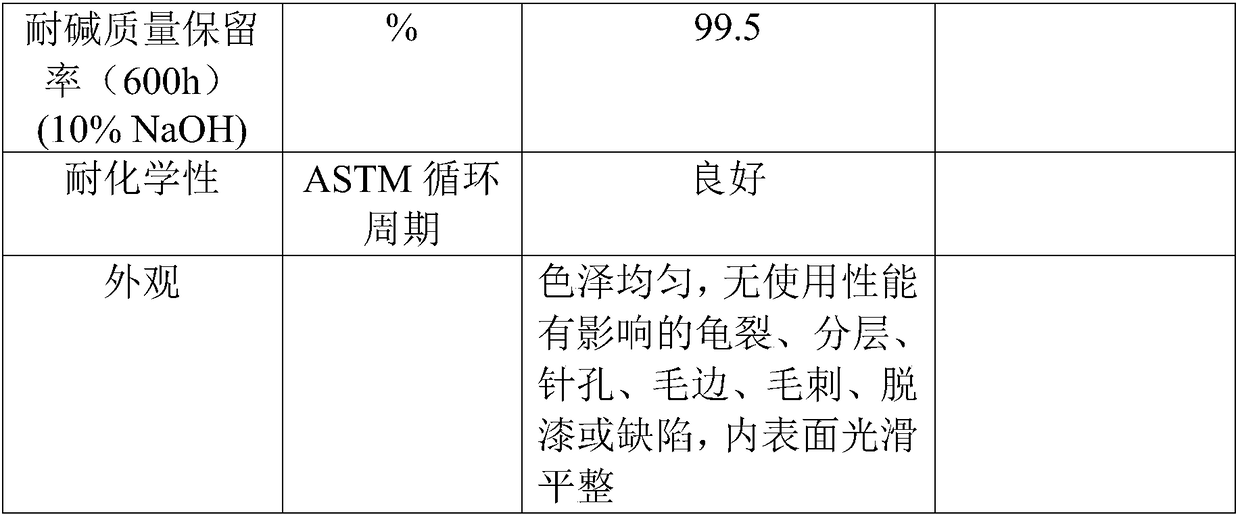

[0024] Such as figure 1 As shown, a strong acid and strong alkali resistant composite pipe made of recycled FRP material includes an outer layer and an inner lining layer, and the outer layer includes the following raw materials in parts by weight: resin 10-20, crushed stone 23-30, quartz sand or river sand 25-30, FRP particle waste and / or FRP powder waste 10-40, the curing agent added in an amount of 1-3% of the weight of the resin, the accelerator added in an amount of 1-3% of the weight of the resin, added The color material is 2-8% of the weight of the resin; the inner liner layer includes the following raw materials in parts by weight: 10-50 of pure vinyl polymer or o-phthalic resin and 50-90 of quartz powder. The resin is preferably o-phthalic resin, the curing agent is preferably methyl ethyl ketone peroxide, the accelerator is preferably cobalt water or benzene, the particle size of the crushed stone is preferably 2-6 mesh, and the particle size of the quartz sand or r...

Embodiment 2

[0032] On the basis of Example 1, the preferred embodiment of the strong acid and strong alkali resistant composite pipe of FRP regenerated material of the present invention, the outer layer includes the following raw materials in parts by weight: the resin 15, the crushed stone 28, the quartz sand Or the river sand 28, the glass fiber reinforced plastic particle waste and the glass fiber reinforced plastic powder waste 36, wherein the particle size is 200-300 purpose of the glass fiber reinforced plastic particle waste and the particle size is the ratio of the 300-400 purpose of the glass fiber reinforced plastic powder waste is 3:7, the addition of the curing agent is 2% of the weight of the resin, the addition of the accelerator is 2% of the weight of the resin, the addition of the colorant is 5% of the weight of the resin %, the inner lining layer includes the following raw materials in parts by weight: pure vinyl polymer or o-phthalic resin 35 and quartz powder 65.

[003...

Embodiment 3

[0037] On the basis of Example 1, the preferred embodiment of the strong acid and strong alkali resistant composite pipe of FRP regenerated material of the present invention, the outer layer includes the following raw materials in parts by weight: the resin 15, the crushed stone 26, the quartz sand Or the river sand 28, the glass fiber reinforced plastic particle waste or the glass fiber reinforced plastic powder waste 32, the addition of the curing agent is 1.5% of the resin weight, and the addition of the accelerator is 1.5% of the resin weight. %, the added amount of the colorant is 5% of the weight of the resin, and the inner lining layer includes the following raw materials in parts by weight: pure vinyl polymer or o-phthalic resin 30 and quartz powder 70 .

[0038] Using the preparation method in Example 1, the raw material formula described in Example 3 can be used to prepare the strong acid and strong alkali resistant composite pipe of FRP regenerated material, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com