Nitrogen-doped reduced graphene oxide modified graphite felt electrode and preparation method thereof

A technology of graphite felt and graphene, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of affecting the electrical properties of the electrodes and reducing the conductivity of the electrodes, and achieve the effect of increasing the specific surface area and reducing the efficiency of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of a nitrogen-doped reduced graphene oxide modified graphite felt electrode, the steps of which are as follows:

[0047] S1, carry out hydrophilic treatment to graphite felt electrode;

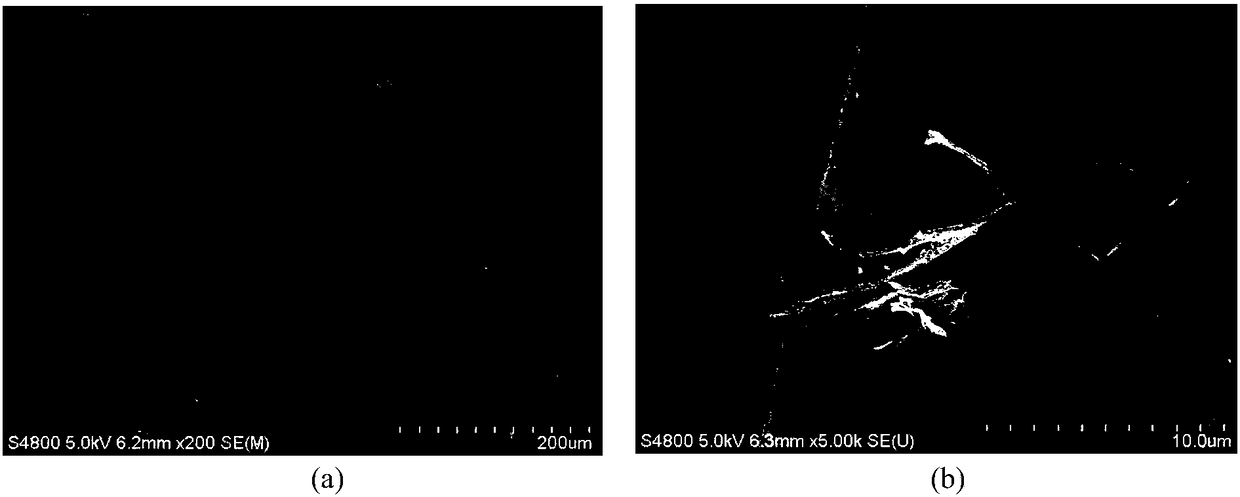

[0048] S2, configure the mixed solution of nitrogen-containing compound and graphene oxide, disperse the mixed solution of nitrogen-containing compound and graphene oxide into the graphite felt electrode through hydrophilic treatment, and freeze-dry to obtain graphene oxide and nitrogen-containing Compound-doped graphite felt composite electrode preform;

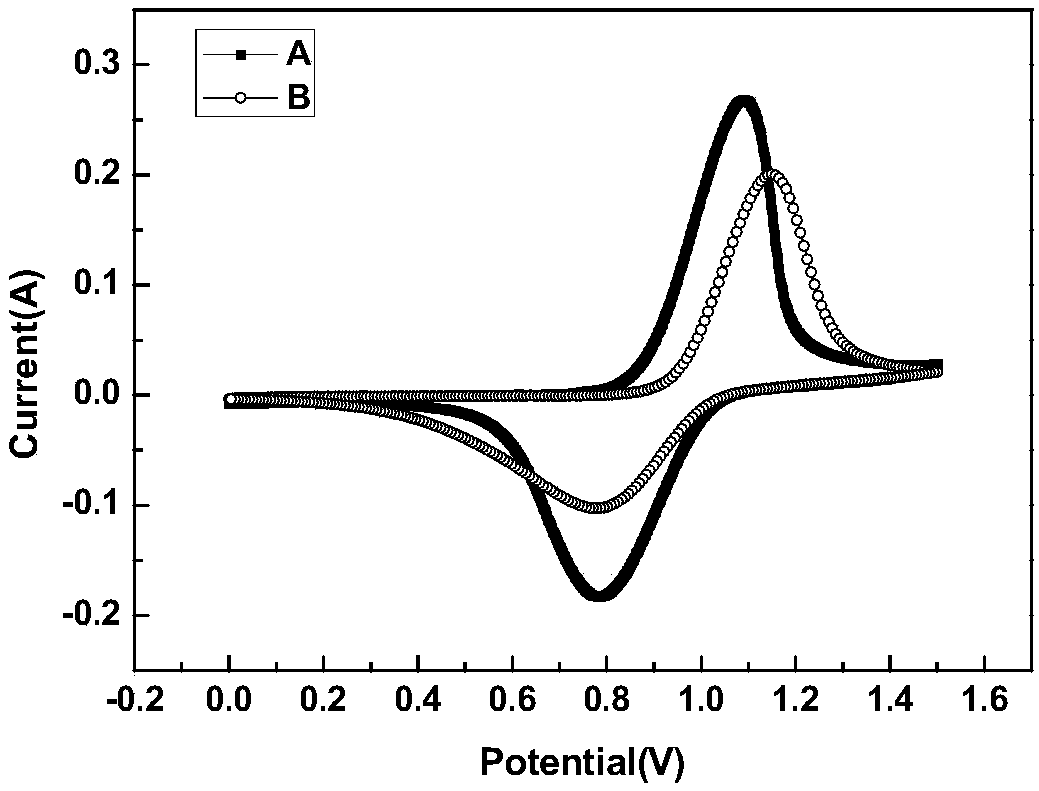

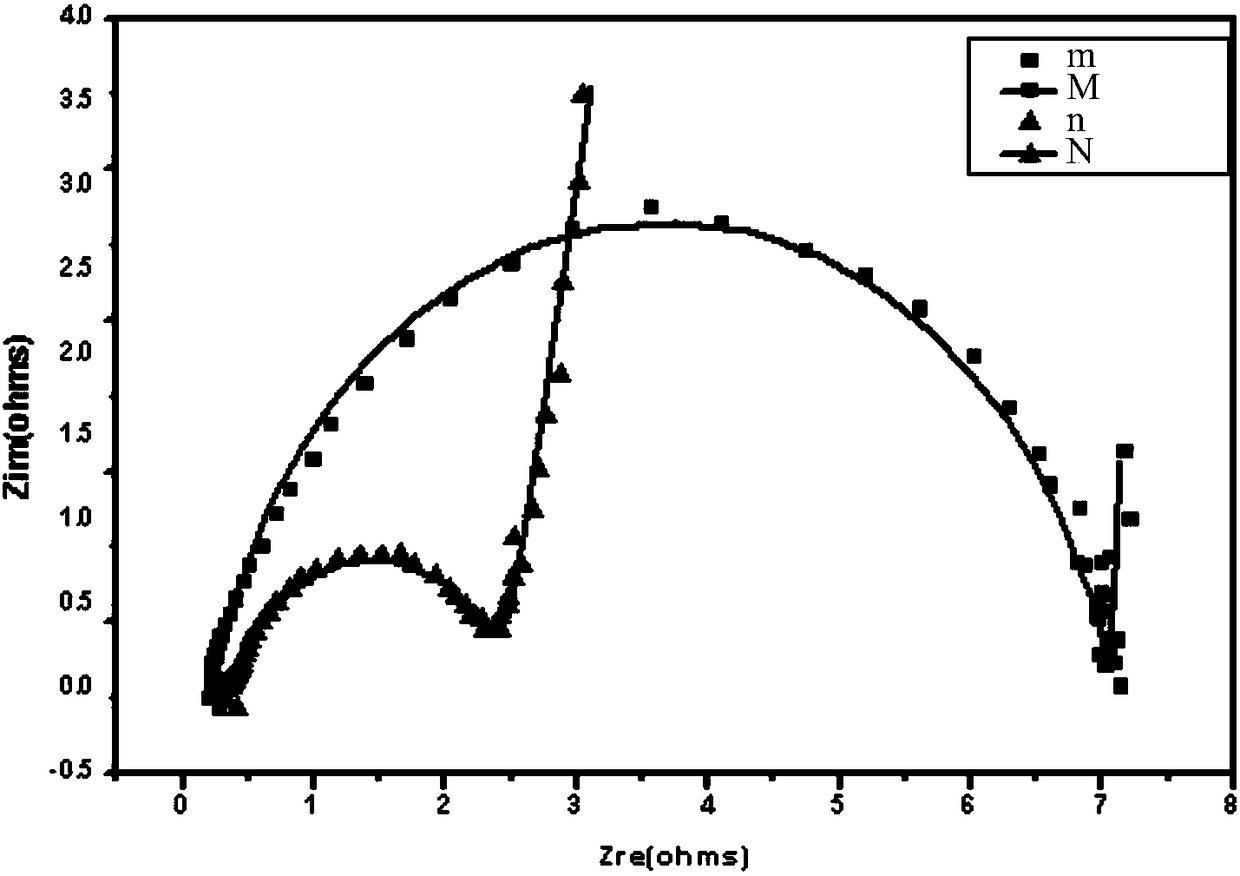

[0049] S3, the graphene oxide prepared in step S2 and the graphite felt composite electrode prefabricated body doped with nitrogen-containing compounds are placed in a tube furnace, and the N 2 Under the protection of atmosphere, the graphene oxide and nitrogen-containing compound doped graphite felt composite electrode preform is heat-treated, so that the nitrogen-containing compound in the graphite felt composi...

Embodiment 2

[0061] A preparation method of a nitrogen-doped reduced graphene oxide modified graphite felt electrode, the steps of which are as follows:

[0062] S1, carry out hydrophilic treatment to graphite felt electrode;

[0063] S2, configure the mixed solution of nitrogen-containing compound and graphene oxide, disperse the mixed solution of nitrogen-containing compound and graphene oxide into the graphite felt electrode through hydrophilic treatment, and freeze-dry to obtain graphene oxide and nitrogen-containing Compound-doped graphite felt composite electrode preform;

[0064] S3, the graphene oxide prepared in step S2 and the graphite felt composite electrode prefabricated body doped with nitrogen-containing compounds are placed in a tube furnace, and the N 2 Under the protection of atmosphere, the graphene oxide and nitrogen-containing compound doped graphite felt composite electrode preform is heat-treated, so that the nitrogen-containing compound in the graphite felt composi...

Embodiment 3

[0071] A preparation method of a nitrogen-doped reduced graphene oxide modified graphite felt electrode, the steps of which are as follows:

[0072] S1, carry out hydrophilic treatment to graphite felt electrode;

[0073] S2, configure the mixed solution of nitrogen-containing compound and graphene oxide, disperse the mixed solution of nitrogen-containing compound and graphene oxide into the graphite felt electrode through hydrophilic treatment, and freeze-dry to obtain graphene oxide and nitrogen-containing Compound-doped graphite felt composite electrode preform;

[0074] S3, the graphene oxide prepared in step S2 and the graphite felt composite electrode prefabricated body doped with nitrogen-containing compounds are placed in a tube furnace, and the N 2 Under the protection of atmosphere, the graphene oxide and nitrogen-containing compound doped graphite felt composite electrode preform is heat-treated, so that the nitrogen-containing compound in the graphite felt composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com