Preparation method of manganese dioxide/graphite oxide-based self-driven micromotor

A nano-manganese dioxide and catalyst technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc. High, expensive catalytic materials and other issues, to achieve the effect of uniform size, good repeatability, and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

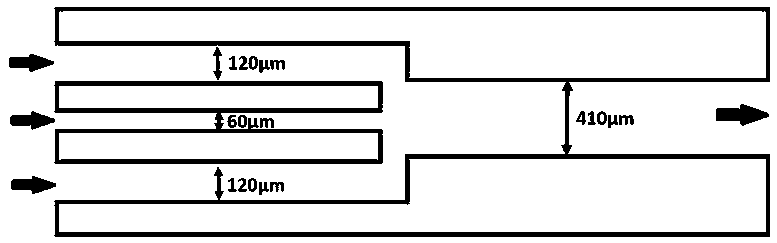

Method used

Image

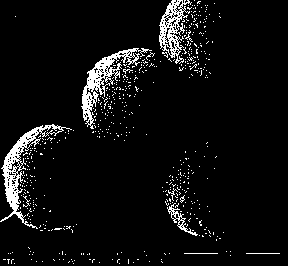

Examples

Embodiment 1

[0028] (1) Preparation of nano manganese dioxide particles

[0029] Weigh 1.94 g of potassium permanganate and 0.845 g of manganese sulfate, dissolve them in a small amount of deionized water, mix them evenly in a high-temperature reactor, heat at 160 °C for 12 hours, and centrifuge the obtained product after cooling , and repeatedly washed with deionized water, dried, and set aside;

[0030] (2) Preparation of precursor solution

[0031] Preparation of the internal phase fluid: The graphene oxide dispersion was prepared by the improved Hummers method, and 7 mL of the graphene oxide aqueous dispersion with a concentration of 10 mg / mL was ultrasonically treated with a 300 W ultrasonic cleaner for 30 min; 3 mL of chitosan-acetic acid solution, wherein the concentration of chitosan is 8 mg / mL, and the mass percent concentration of acetic acid is 2.5%, is added to the above-mentioned graphene oxide solution, and ultrasonic cleaning with a power of 300 W is performed for 30 min to...

Embodiment 2

[0042] (1) Preparation of nano manganese dioxide particles

[0043]Weigh 1.94 g of potassium permanganate and 0.845 g of manganese sulfate, dissolve them in a small amount of deionized water, mix them evenly in a high-temperature reactor, heat at 160 °C for 12 hours, and centrifuge the obtained product after cooling , and repeatedly washed with deionized water, dried, and set aside;

[0044] (2) Preparation of precursor solution

[0045] Preparation of the internal phase fluid: The graphene oxide dispersion was prepared by the improved Hummers method, and 7 mL of the graphene oxide aqueous dispersion with a concentration of 5 mg / mL was ultrasonically treated with a 300 W ultrasonic cleaner for 30 min; 3 mL of chitosan-acetic acid solution, wherein the concentration of chitosan is 8 mg / mL, and the mass percent concentration of acetic acid is 2.5%, is added to the above-mentioned graphene oxide solution, and ultrasonic cleaning with a power of 300 W is performed for 30 min to o...

Embodiment 3

[0055] (1) Preparation of nano manganese dioxide particles

[0056] Weigh 1.94 g of potassium permanganate and 0.845 g of manganese sulfate, dissolve them in a small amount of deionized water, mix them evenly in a high-temperature reactor, heat at 160 °C for 12 hours, and centrifuge the obtained product after cooling , and repeatedly washed with deionized water, dried, and set aside;

[0057] (2) Preparation of precursor solution

[0058] Preparation of the internal phase fluid: The graphene oxide dispersion was prepared by the improved Hummers method, and 7 mL of the graphene oxide aqueous dispersion with a concentration of 20 mg / mL was ultrasonically treated with a 300 W ultrasonic cleaner for 30 min; 3 mL of chitosan-acetic acid solution, wherein the concentration of chitosan is 2 mg / mL, and the mass percent concentration of acetic acid is 2.5%, is added to the above-mentioned graphene oxide solution, and ultrasonic cleaning with a power of 300 W is performed for 30 min to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com