Nickel phosphide, preparation method thereof and method for producing hydrogen through water electrolysis

A technology of phosphide and electrolysis of water, which is applied in chemical instruments and methods, catalyst activation/preparation, electrolysis process, etc. It can solve the problems of difficult control of the reaction process, inability to adapt to production needs, harsh reaction conditions, etc., and achieve good electrolysis of water for hydrogen evolution Performance, low hydrogen evolution potential of electrolyzed water, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of nickel phosphide, comprising the following steps:

[0029] a) dissolving the nickel source compound, phosphorus source compound and acetate in water to obtain a solution;

[0030] b) performing electrodeposition treatment on the solution to obtain nickel phosphide.

[0031] In the preparation method provided by the invention, the nickel source compound, phosphorus source compound and acetate are dissolved in water to obtain a solution, and then the solution is subjected to electrodeposition treatment to obtain nickel phosphide. The preparation method provided by the invention is simple and easy, has mild conditions, low cost, safety and environmental protection, has no by-products, and is suitable for large-scale production.

[0032] According to the present invention, the nickel source compound, phosphorus source compound and acetate are dissolved in water to obtain a solution.

[0033] In the present invention, ...

Embodiment 1

[0049] 1.1 Sample preparation

[0050] Add nickel nitrate hexahydrate, sodium acetate and sodium hypophosphite in a molar ratio of 1:2:10 to the adaptive electrolytic cell (the cell volume is 100mL, and the total molar amount of all raw materials is 0.65mol), and add a conductivity of 18.5MΩ.cm 50 mL of deionized water was dissolved to obtain a solution. Using a three-electrode system (with a glassy carbon electrode as a working electrode, an Ag / AgCl electrode filled with saturated KCl as a reference electrode, and a platinum wire as a counter electrode), the resulting solution was subjected to linear cyclic voltammetry scanning electrodeposition treatment, and the electrodeposition temperature was At 20°C, with a deposition potential of -0.2V to -1.0V, and a scan rate of 5mV / s, nickel phosphide was obtained after treatment for 160 seconds.

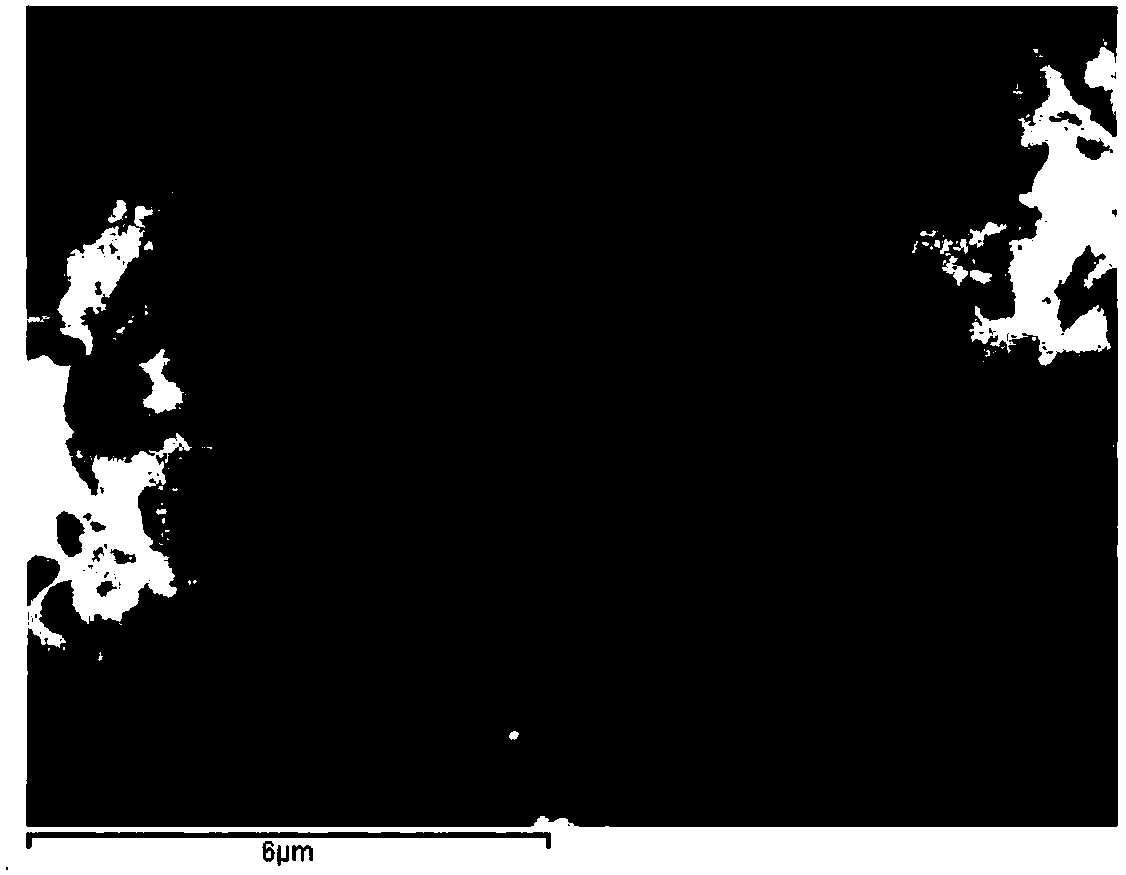

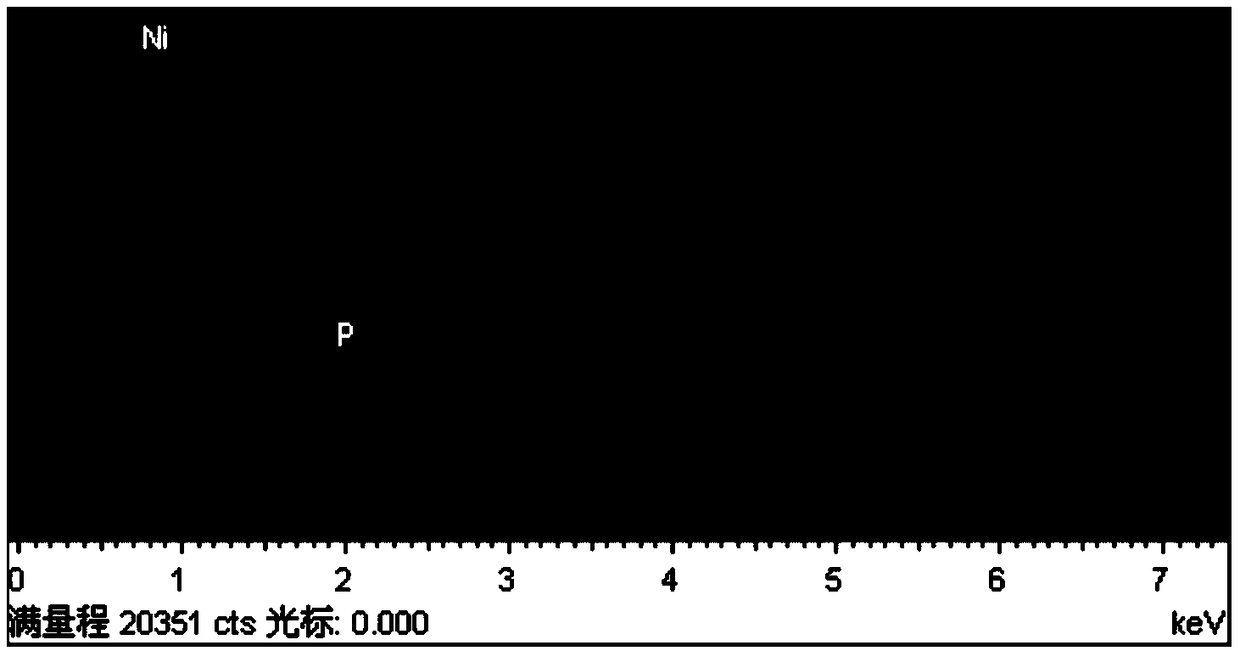

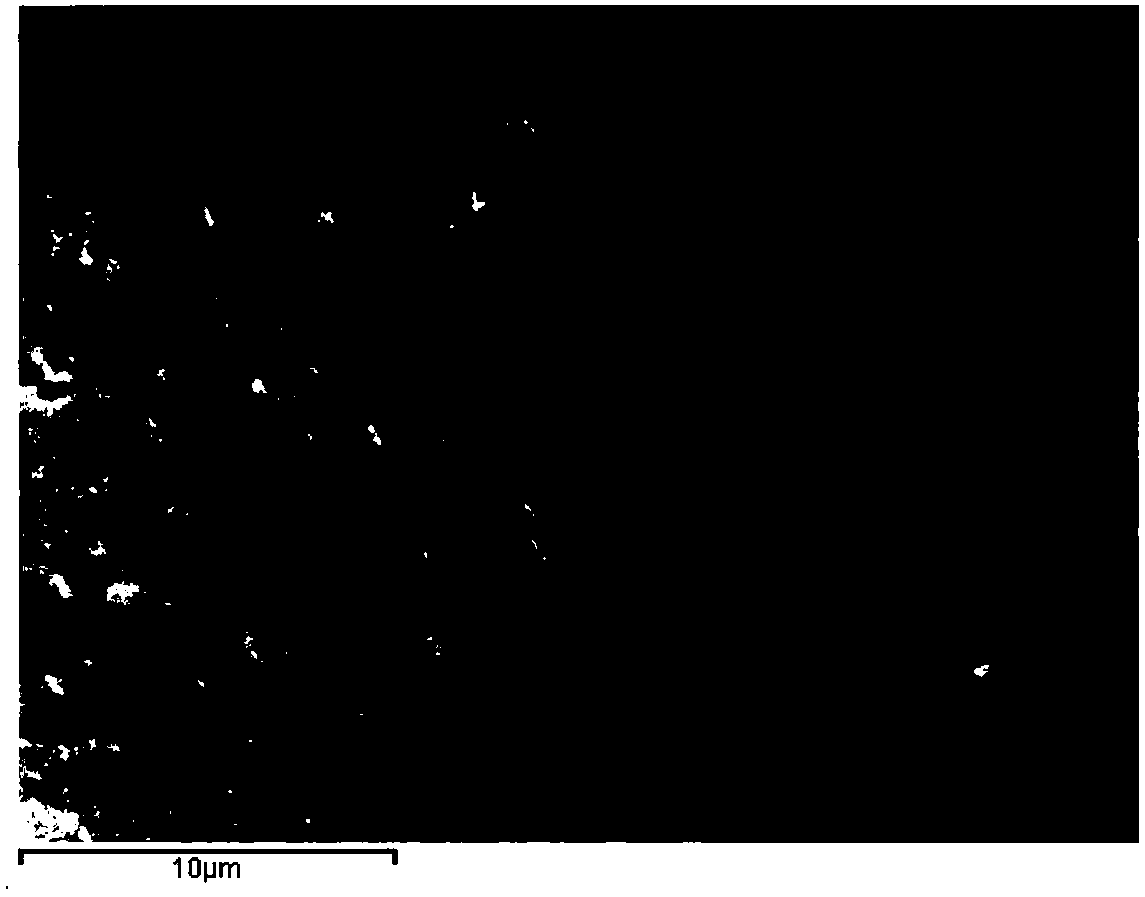

[0051] 1.2 Sample Characterization

[0052] (1) Gained product is carried out scanning electron microscope test, the result is as foll...

Embodiment 2

[0061] 1.1 Hydrogen evolution effect test of electrolyzed water

[0062] The nickel phosphides prepared in Example 1 and Comparative Example 1 (the nickel phosphides in Example 1 and Comparative Example 1 take the same amount) were used as electrolytic water hydrogen evolution catalysts to carry out electrolytic water hydrogen evolution tests, and a clean glassy carbon electrode was used as a blank Control (denoted as Comparative Example 2). details as follows:

[0063] The glassy carbon electrode deposited with nickel phosphide in Example 1, the glassy carbon electrode compounded with nickel phosphide in Comparative Example 1, and the clean glassy carbon electrode in Comparative Example 2 were respectively used as working electrodes, and Ag / AgCl was used as a reference electrode. The saturated KCl solution with a concentration of 3mol / L is used as the reference electrode filling solution, and the linear cycle scanning test is performed under the same conditions (ie 0.1mol / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com