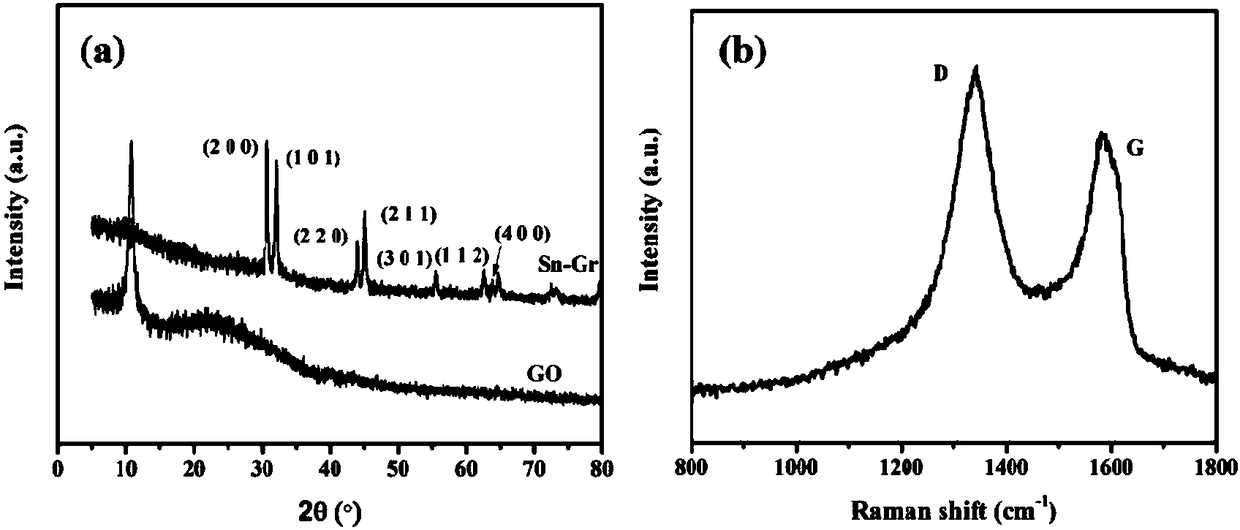

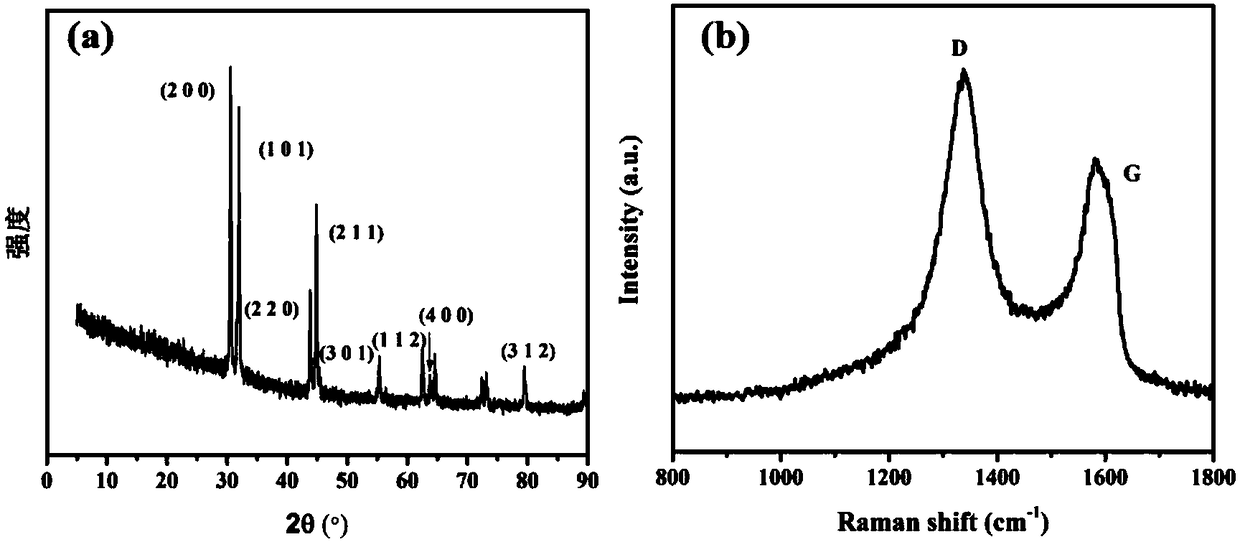

Solvothermal coreduction method for preparing tin/graphene nanometer composite material

A technology of nanocomposite materials and graphene, which is applied in the field of solvothermal co-reduction method for preparing tin/graphene nanocomposite materials, can solve the problems of complex process and high cost, and achieve the effects of simple operation, low cost and high reduction degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The solvothermal co-reduction method of preparing tin / graphene nanocomposite material in the present embodiment is as follows:

[0023] 1. Take 2.5ml of graphene oxide ethanol solution with a concentration of 3mg / ml and ultrasonically disperse for 1 hour, and set aside;

[0024] Dissolve 200mg of polyvinylpyrrolidone in 20ml of ethanol to prepare a solution for later use;

[0025] Dissolve 90mg of tin protochloride dihydrate in 10ml of ethanol to make a solution for later use;

[0026] Dissolve 200ml of sodium borohydride in 20ml of ethanol to make a solution for later use.

[0027] 2. At room temperature, add the ethanol solution of polyvinylpyrrolidone, the ethanol solution of stannous chloride dihydrate and the ethanol solution of graphene oxide into the reactor in sequence, and mix them evenly in an argon atmosphere;

[0028] 3. Add the ethanol solution of sodium borohydride to the mixed solution obtained in step 1, stir evenly at room temperature, and then perfor...

Embodiment 2

[0030] The solvothermal co-reduction method of preparing tin / graphene nanocomposite material in the present embodiment is as follows:

[0031] 1. Take 2.5ml of graphene oxide ethanol solution with a concentration of 3mg / ml and ultrasonically disperse for 1 hour, and set aside;

[0032] Dissolve 200mg of polyvinylpyrrolidone in 20ml of ethanol to prepare a solution for later use;

[0033] Dissolve 120mg of tin protochloride dihydrate in 10ml of ethanol to make a solution for later use;

[0034] Dissolve 200ml of sodium borohydride in 20ml of ethanol to make a solution for later use.

[0035] 2. At room temperature, add the ethanol solution of polyvinylpyrrolidone, the ethanol solution of stannous chloride dihydrate and the ethanol solution of graphene oxide into the reactor in sequence, and mix them evenly in an argon atmosphere;

[0036] 3. Add the ethanol solution of sodium borohydride to the mixed solution obtained in step 1, stir evenly at room temperature, and then perfo...

Embodiment 3

[0038] The solvothermal co-reduction method of preparing tin / graphene nanocomposite material in the present embodiment is as follows:

[0039] 1. Take 2.5ml of graphene oxide ethanol solution with a concentration of 3mg / ml and ultrasonically disperse for 1 hour, and set aside;

[0040] Dissolve 100mg of polyvinylpyrrolidone in 20ml of ethanol to prepare a solution for later use;

[0041] Dissolve 90mg of tin protochloride dihydrate in 10ml of ethanol to make a solution for later use;

[0042] Dissolve 100ml of sodium borohydride in 20ml of ethanol to make a solution for later use.

[0043] 2. At room temperature, add the ethanol solution of polyvinylpyrrolidone, the ethanol solution of stannous chloride dihydrate and the ethanol solution of graphene oxide into the reactor in sequence, and mix them evenly in an argon atmosphere;

[0044] 3. Add the ethanol solution of sodium borohydride to the mixed solution obtained in step 1, stir evenly at room temperature, and then perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com