Preparation method of flawless graphene

A graphene, defect-free technology, applied in the field of preparation of defect-free graphene, can solve the problems affecting the mechanical properties, electrical conductivity and thermal properties of graphene, reduce the theoretical performance of graphene, reduce the performance of samples, etc., and achieve low production cost , Complete lattice structure and small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

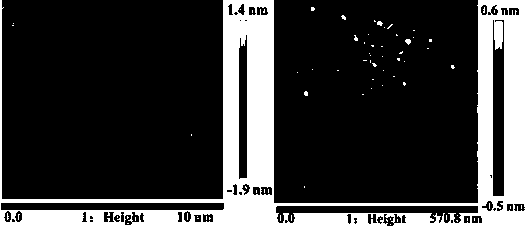

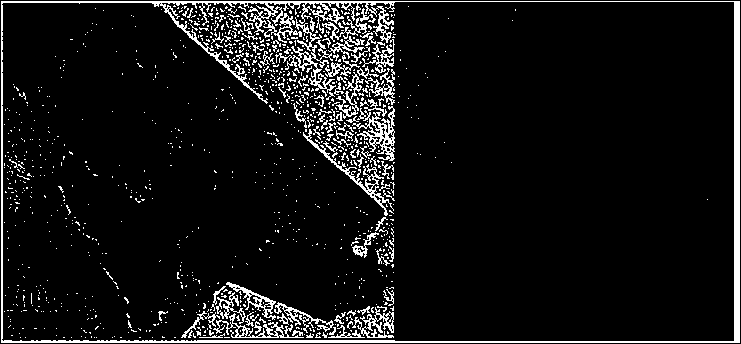

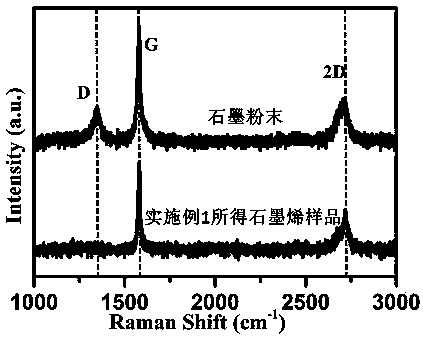

Image

Examples

Embodiment 1

[0025] S1. Disperse 50 mg of graphite powder (original graphite powder without any pretreatment and / or modification) in 10 mL of ethanol (analytical grade) and 30wt% hydrogen peroxide in a volume ratio of 2:8 In the mixed solvent, then dissolve 200mg of surfactant polyvinylpyrrolidone in the above mixed solution, and sonicate for 3 h;

[0026] S2. Place the solution obtained after the ultrasonic treatment of S1 in a supercritical reactor, set the reaction temperature and pressure to 40°C and 20 MPa respectively, and after 3 hours of reaction, take out the reaction solution and perform ultrasonic treatment on it for 3 hours;

[0027] S3. The solution obtained after ultrasonic treatment of S2 was subjected to the first centrifugation at 6000 rpm for 40 minutes, and then the second centrifugation was performed at 20000 rpm for 20 minutes after taking the upper layer solution. Centrifuge for 30 minutes, repeat the ethanol washing and centrifugation process 3 times;

[0028] S4, d...

Embodiment 2

[0034] The difference from Example 1 is that in S2, the reaction pressure is changed to 12, 14, 16 and 18 MPa; others are the same as in Example 1.

Embodiment 3

[0036] The difference from Example 1 is that in S2, the reaction temperature is changed to 60 and 80 °C; others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com