A micron-level strong salt spray and water-repellent circuit board conformal paint

A salt-spray-resistant, micron-scale technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of applying conformal coatings to substances without perfluoropolyether chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

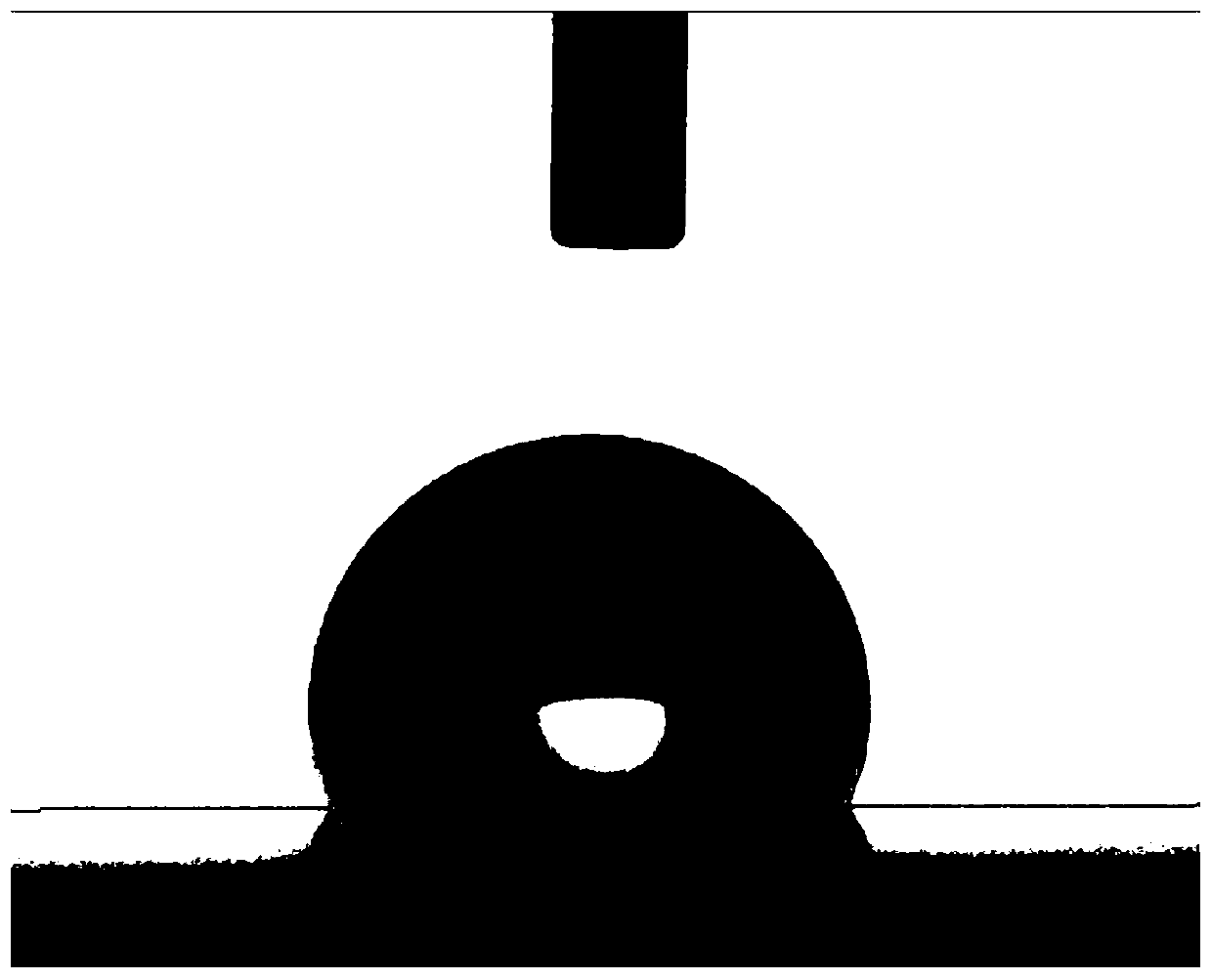

Image

Examples

Embodiment 1

[0055] This embodiment provides a three-proof paint, which is prepared through the following steps:

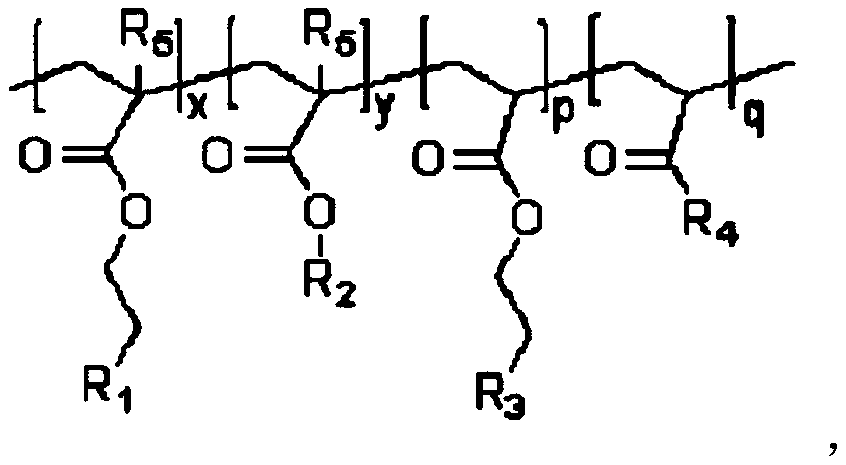

[0056] (1) Preparation of perfluoropolyether modified acrylate polymer:

[0057] In a 500mL four-necked flask equipped with a thermometer, reflux condenser and nitrogen replacement, add 50.00g CF 3 CF 2 CF 2 O[CF(CF 3 )CF 2 O] 8.7 CF(CF 3 )CH 2 CH 2 OC(O)C(CH 3 )=CH 2 , 14.00g butyl acrylate, 34.00g cyclohexyl methacrylate, 1.00g methacrylic acid, 1.00g azobisisobutyronitrile initiator and 233.00g nonafluorobutyl ethyl ether solvent. After replacing with nitrogen, the oil bath was heated to 75°C and reacted for 10 hours. After the reaction is completed, a polymer product with a solid content of 30% is obtained.

[0058] (2) Preparation of three anti-paints:

[0059] The polymer product with a solid content of 30% prepared in step (1) is diluted to 2% with nonafluorobutyl methyl ether to obtain a conformal paint.

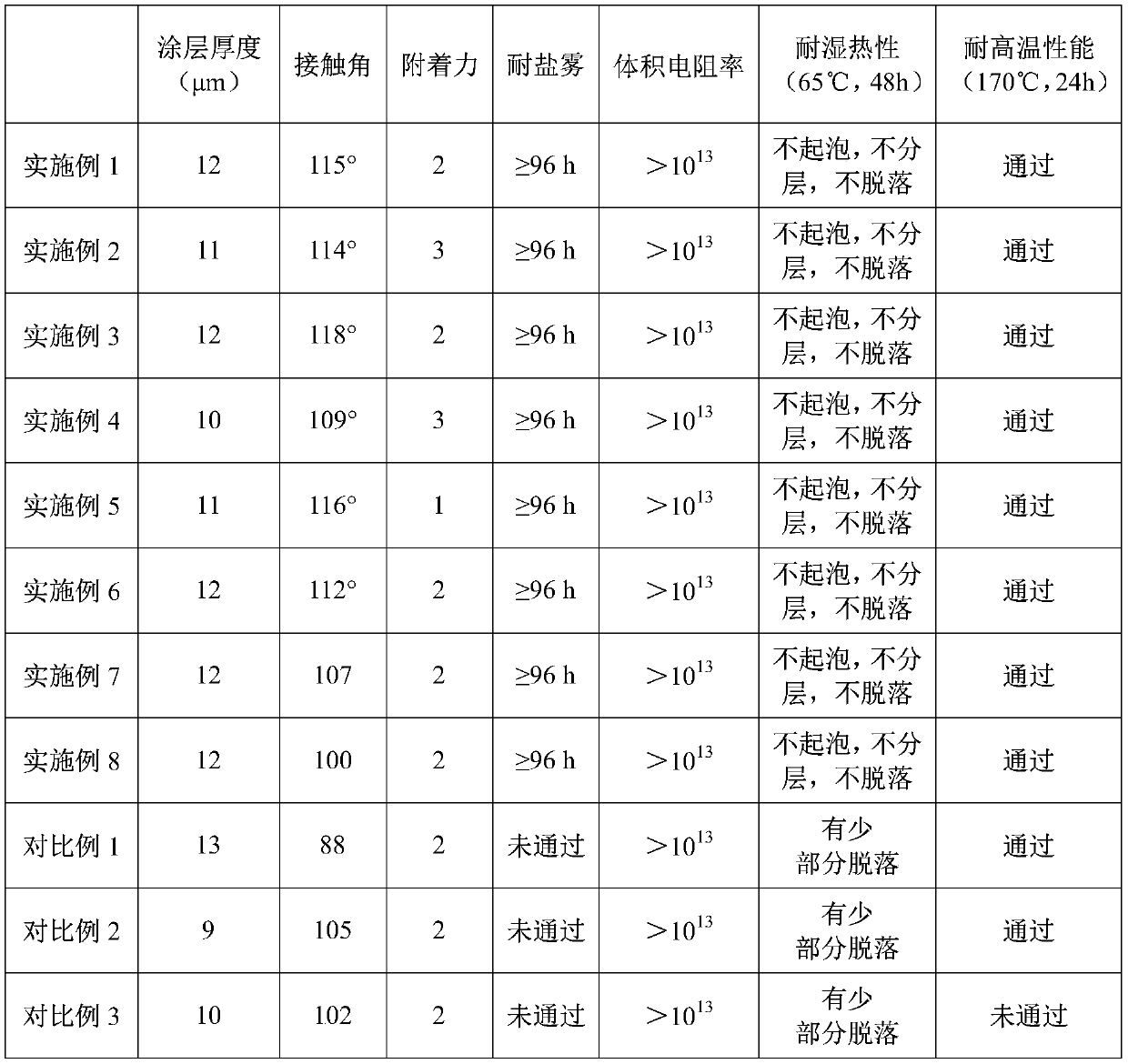

[0060] The three-proof paint prepared in this embodiment is sprayed on ...

Embodiment 2

[0062] This embodiment provides a three-proof paint, which is prepared through the following steps:

[0063] (1) Preparation of perfluoropolyether modified acrylate polymer:

[0064] In a 500mL four-necked flask equipped with a thermometer, reflux condenser and nitrogen replacement, add 50.00g CF 3 CF 2 CF 2 O[CF(CF 3 )CF 2 O] 9.2 CF(CF 3 )CH 2 CH 2 OC(O)CH=CH 2 , 14.00g octyl acrylate, 34.00g benzyl methacrylate, 1.00g methacrylic acid, 1.00g azobisisobutyronitrile initiator and 233.00g nonafluorobutyl ethyl ether solvent. After replacing with nitrogen, the oil bath was heated to 75°C and reacted for 10 hours. After the reaction is completed, a polymer product with a solid content of 30% is obtained.

[0065] (2) Preparation of three anti-paints:

[0066] The polymer product with a solid content of 30% prepared in step (1) is diluted to 5% with nonafluorobutyl methyl ether to obtain a conformal paint.

[0067] The three-proof paint prepared in this embodiment is sprayed on the circui...

Embodiment 3

[0069] This embodiment provides a three-proof paint, which is prepared through the following steps:

[0070] (1) Preparation of perfluoropolyether modified acrylate polymer:

[0071] In a 500mL four-neck flask equipped with a thermometer, reflux condenser and nitrogen replacement, add 60.00g CF 3 CF 2 CF 2 O[CF(CF 3 )CF 2 O] 21.1 CF(CF 3 )CON(H)CH 2 CH 2 OC(O)C(CH 3 )=CH 2 , 4.00g lauryl acrylate, 34.00g isobornyl methacrylate, 1.00g acrylic acid, 1.00g azobisisobutyronitrile initiator and 233.00g nonafluorobutyl ethyl ether solvent. After replacing with nitrogen, the oil bath was heated to 75°C and reacted for 10 hours. After the reaction is completed, a product with a solid content of 30% is obtained.

[0072] (2) Preparation of three anti-paints:

[0073] The polymer product with a solid content of 30% prepared in step (1) is diluted to 10% with nonafluorobutyl methyl ether to obtain a conformal paint.

[0074] The three-proof paint prepared in this embodiment is sprayed on the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com