Method for increasing fermentation yield of artemisinic acid

A technology for increasing the yield of artemisinic acid, which is applied in the field of increasing the fermentation yield of artemisinic acid, can solve problems such as high cost, low yield, and unstable strain performance, and achieve the goals of increasing fermentation yield, reducing fermentation cost, and increasing fermentation titer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

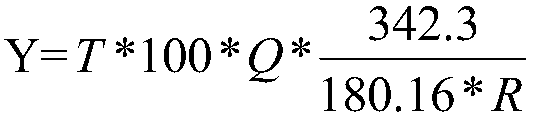

Method used

Image

Examples

Embodiment 1

[0065] (1) Activation of strains: Inoculate the Saccharomyces cerevisiae engineered strains frozen at -80°C into the seed medium according to the inoculum size of 0.5%, and cultivate for 16 hours to obtain the strain liquid;

[0066] (2) Resistance screening of bacterial classification: the bacterial classification liquid gained in the step (1) is diluted 10 -7 After doubling, draw 100 μL and spread it on the plate solid medium containing 200 μg / L hygromycin B, culture for 40 hours, and obtain a single colony of Saccharomyces cerevisiae engineered bacteria;

[0067] The plate solid medium formula is: glucose 19.5g / L, (NH4) 2 SO 4 15g / L, KH 2 PO 4 8g / L, MgSO 4 ·7H 2 O 6.2g / L, vitamin solution 12ml / L, metal ion solution 10ml / L, CuSO 4 ·5H 2 O 40ug / L, succinic acid buffer 100ml / L (0.5M, pH 5.0), agar 20g / L, and the rest are water.

[0068] (3) Seed culture: Pick a single colony from the plate solid medium containing antibiotics, inoculate it into the seed medium, and cu...

Embodiment 2

[0076] (1) Activation of strains: inoculate the Saccharomyces cerevisiae engineered strains frozen at -80°C into the seed medium according to the inoculation amount of 0.1% (V / V), cultivate for 30 hours, and obtain the strain liquid;

[0077] (2) Resistance screening of bacterial classification: the bacterial classification liquid gained in the step (1) is diluted 10 -5 After doubling, draw 100 μL and spread it on the plate solid medium containing 300 μg / L knorsmycin, cultivate for 30 hours, and obtain a single colony of Saccharomyces cerevisiae engineering bacteria;

[0078] The plate solid medium formula is: glucose 19.5g / L, (NH4) 2 SO 4 15g / L, KH 2 PO 4 8g / L, MgSO 4 ·7H 2 O 6.2g / L, vitamin solution 12ml / L, metal ion solution 10ml / L, CuSO 4 ·5H 2 O40ug / L, succinic acid buffer 100ml / L (0.5M, pH 5.0), agar 20g / L, and the rest are water.

[0079] (3) Seed culture: Pick a single colony from the plate solid medium containing antibiotics, inoculate it into the seed mediu...

Embodiment 3

[0087] (1) Preparation of the seed liquid: Inoculate the Saccharomyces cerevisiae engineered strains frozen at -80°C into the seed culture medium according to the inoculum size of 0.3%, and cultivate for 20 hours to obtain the seed liquid;

[0088] (2) Resistance screening of bacterial classification: the bacterial classification liquid gained in the step (1) is diluted 10 -6 After doubling, draw 100 μL and spread it on the plate solid medium containing 250 μg / L geneticin, culture for 35 hours, and obtain a single colony of Saccharomyces cerevisiae engineered bacteria;

[0089] The plate solid medium formula is: glucose 19.5g / L, (NH4) 2 SO 4 15g / L, KH 2 PO 4 8g / L, MgSO 4 ·7H 2 O 6.2g / L, vitamin solution 12ml / L, metal ion solution 10ml / L, CuSO 4 ·5H 2 O 40ug / L, succinic acid buffer 100ml / L (0.5M, pH 5.0), agar 20g / L, and the rest are water.

[0090] (3) Seed culture: Pick a single colony from the plate solid medium containing antibiotics, inoculate it into the seed me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com