Method for deep eutectic solvent extraction and macroporous resin separation and purification of burdock leaf total flavonoids

A low eutectic solvent, separation and purification technology, applied in the field of low eutectic solvent extraction, macroporous adsorption resin separation and purification of burdock leaf total flavonoids, can solve the problems of low extraction rate, environmental pollution, lack of systemicity, etc., and achieves simple operation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

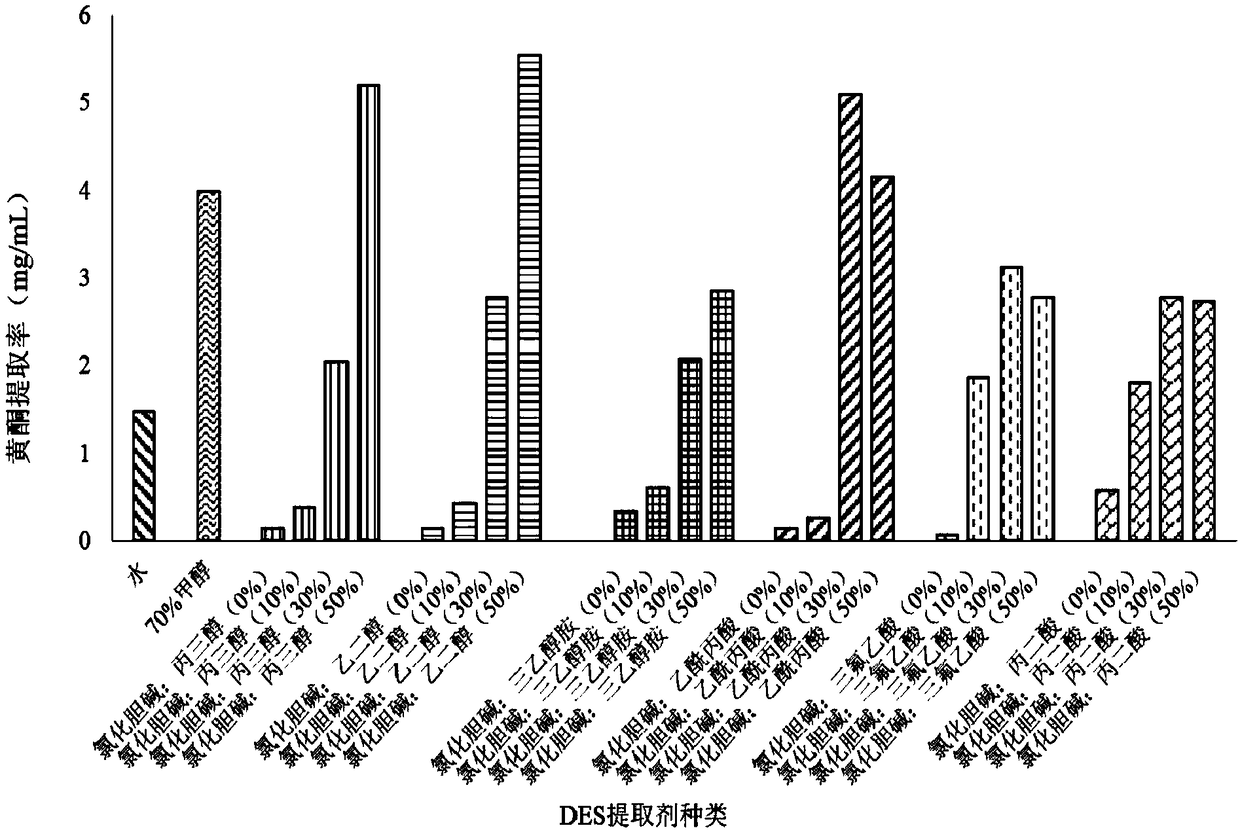

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of deep eutectic solvent: Choline chloride and ethylene glycol were mixed in a molar ratio of 1:2 in a reactor with a drying tube, heated to 80°C, and stirred for 2 hours until a transparent and uniform solvent was formed.

[0020] (2) Preparation of extraction solvent: do not add deionized water to the deep eutectic solvent prepared in step (1), and prepare an extraction solvent with a water content of the deep eutectic solvent of 0%.

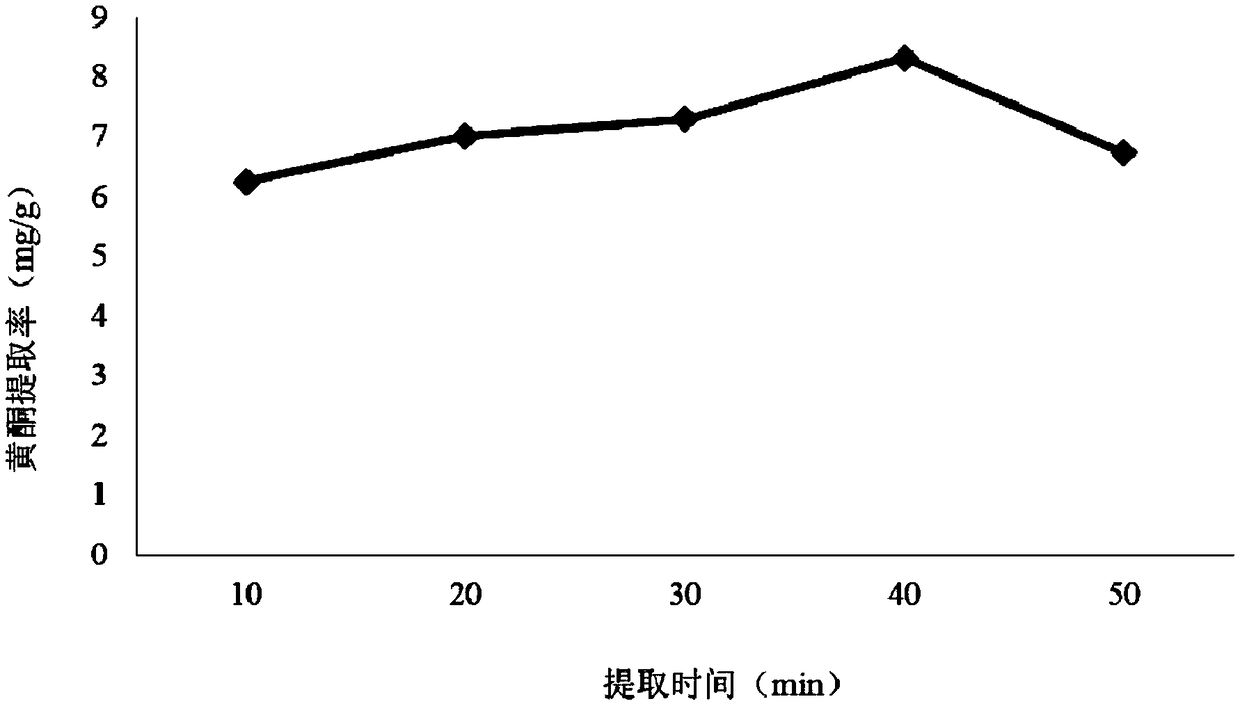

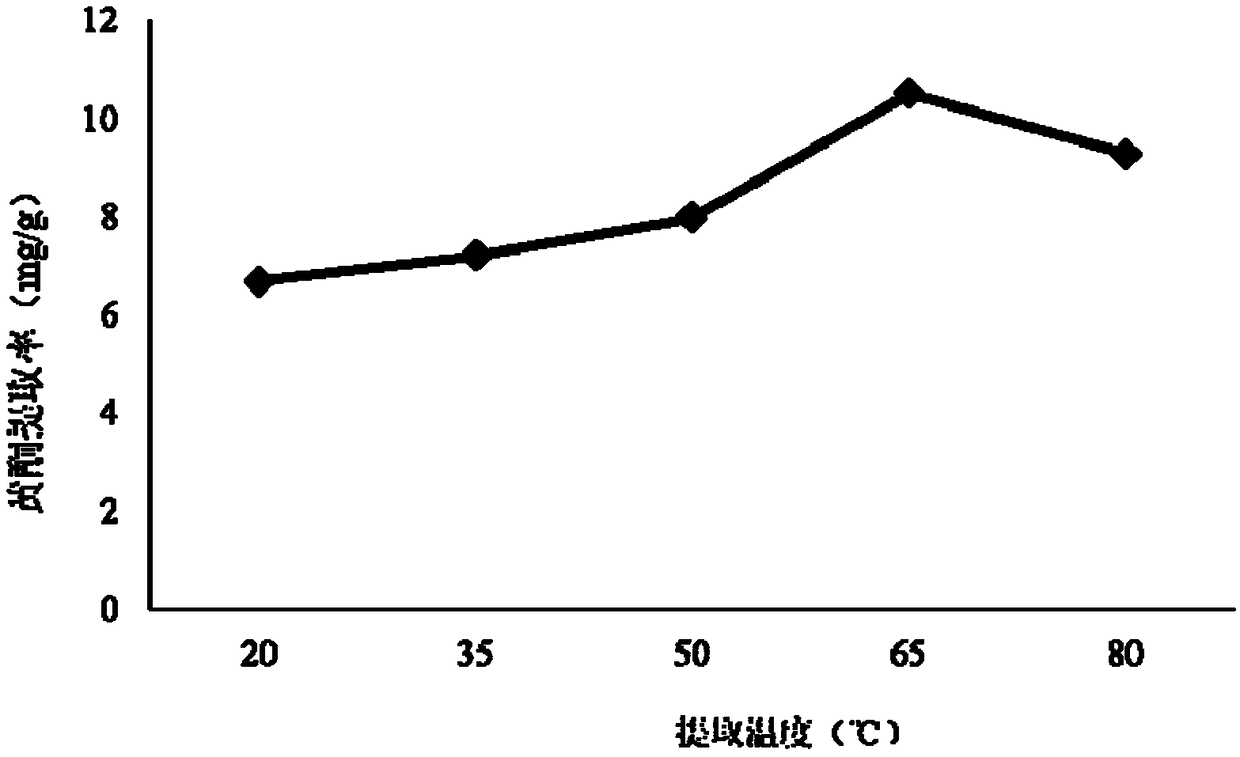

[0021] (3) Extraction: the burdock leaves are washed, dried, and pulverized, and the burdock leaf powder and the extraction solvent prepared in step (2) are placed in a reaction vessel at a solid-to-liquid ratio of 10:1 mg / mL. Put the above materials in an ultrasonic-assisted extractor, and conduct an ultrasonic-assisted extraction for 20 minutes at 35°C and an ultrasonic power of 150W to obtain an extract, and filter the extract to obtain the crude extract of burdock leaves, total flavonoids of burdock leaves The extrac...

Embodiment 2

[0024] (1) Preparation of deep eutectic solvent: Choline chloride and ethylene glycol were mixed in a molar ratio of 1:2 in a reactor with a drying tube, heated to 80°C, and stirred for 2 hours until a transparent and uniform solvent was formed.

[0025] (2) Preparation of the extraction solvent: add an appropriate amount of deionized water to the deep eutectic solvent prepared in step (1) to prepare an extraction solvent with a water content of the deep eutectic solvent of 50%.

[0026] (3) Extraction: the burdock leaves are washed, dried, and pulverized, and the burdock leaf powder and the extraction solvent prepared in step (2) are placed in a reaction vessel at a solid-to-liquid ratio of 20:1 mg / mL. Put the above materials in an ultrasonic-assisted extractor, and conduct an ultrasonic-assisted extraction for 40 minutes at 65°C and an ultrasonic power of 300W to obtain an extract, and filter the extract to obtain the crude extract of burdock leaves, total flavonoids of burdo...

Embodiment 3

[0029] (1) Preparation of deep eutectic solvent: Choline chloride and ethylene glycol were mixed in a molar ratio of 1:2 in a reactor with a drying tube, heated to 80°C, and stirred for 2 hours until a transparent and uniform solvent was formed.

[0030] (2) Preparation of the extraction solvent: add an appropriate amount of deionized water to the deep eutectic solvent prepared in step (1) to prepare an extraction solvent with a water content of the deep eutectic solvent of 30%.

[0031] (3) Extraction: the burdock leaves are washed, dried, and pulverized, and the burdock leaf powder and the extraction solvent prepared in step (2) are placed in a reaction vessel at a solid-to-liquid ratio of 40:1 mg / mL. Put the above materials in an ultrasonic-assisted extractor, and conduct an ultrasonic-assisted extraction for 50 minutes at 80°C and an ultrasonic power of 350W to obtain an extract, which is subjected to suction filtration to obtain the crude extract of burdock leaves, total f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com