Efficient and deep chemically reduced debromination treatment method for polybrominated diphenyl ether

A technology of polybrominated diphenyl ethers and a disposal method is applied in the field of high-efficiency and deep chemical reduction debromination disposal of polybrominated diphenyl ethers, can solve problems such as slow debromination efficiency of PBDEs, and achieve the effects of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 A high-efficiency deep chemical reduction debromination treatment method for polybrominated diphenyl ethers, comprising the following steps:

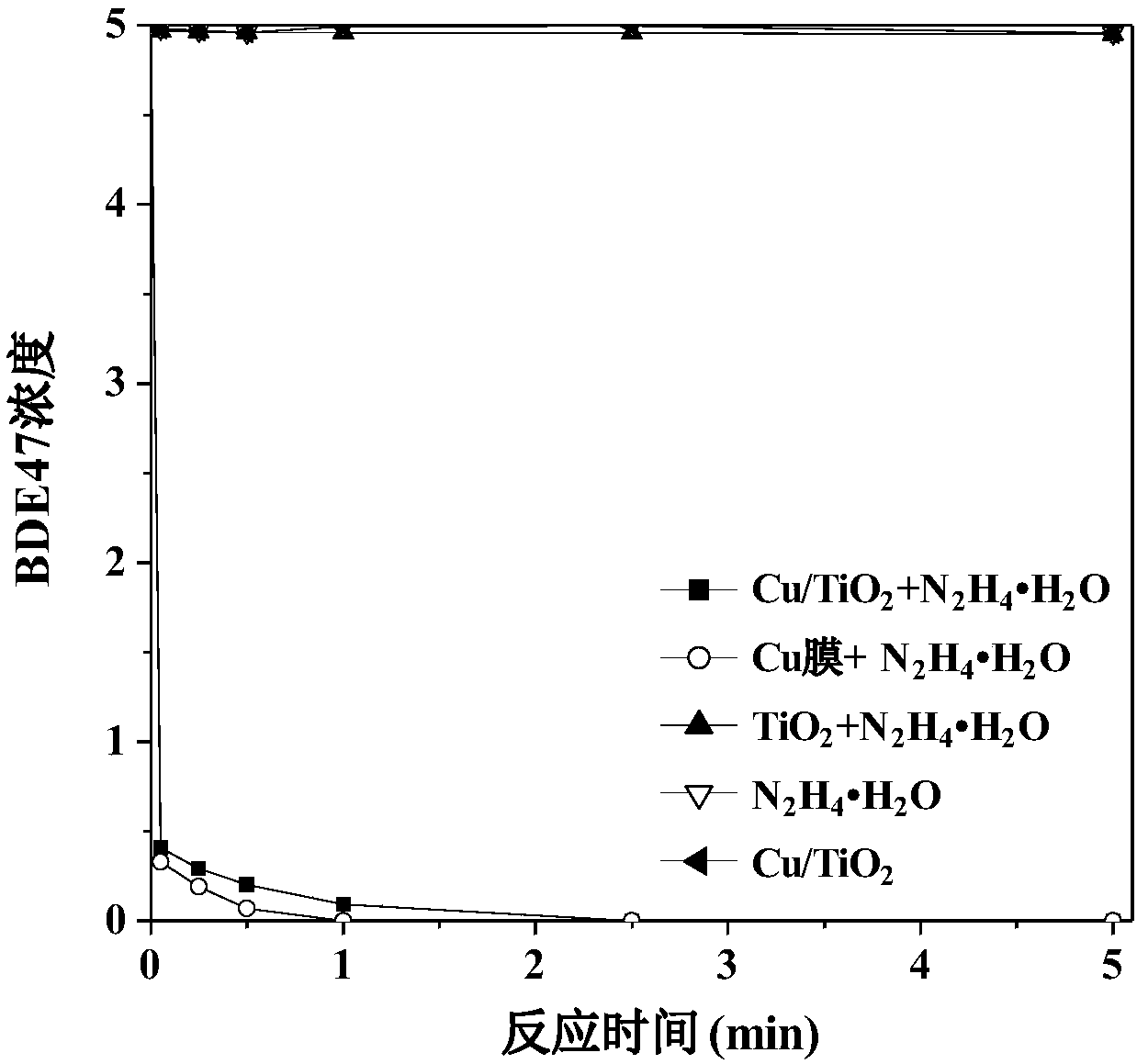

[0031] Step 1: Weigh 10mg TiO 2 Supported nano-Cu catalyst (Cu / TiO 2 , where the mass fraction of Cu is 2%) in a beaker, add 48mL of methanol and 2mL of 2,2',4,4'-tetrabromodiphenyl ether (hereinafter referred to as BDE47) stock solution (1000mg L -1 , is the methanol solution of BDE47) and ultrasonically disperses evenly, so that the concentration of the catalyst in the dispersion is 0.2g L -1 , the initial concentration of BDE47 was 40mg·L -1 .

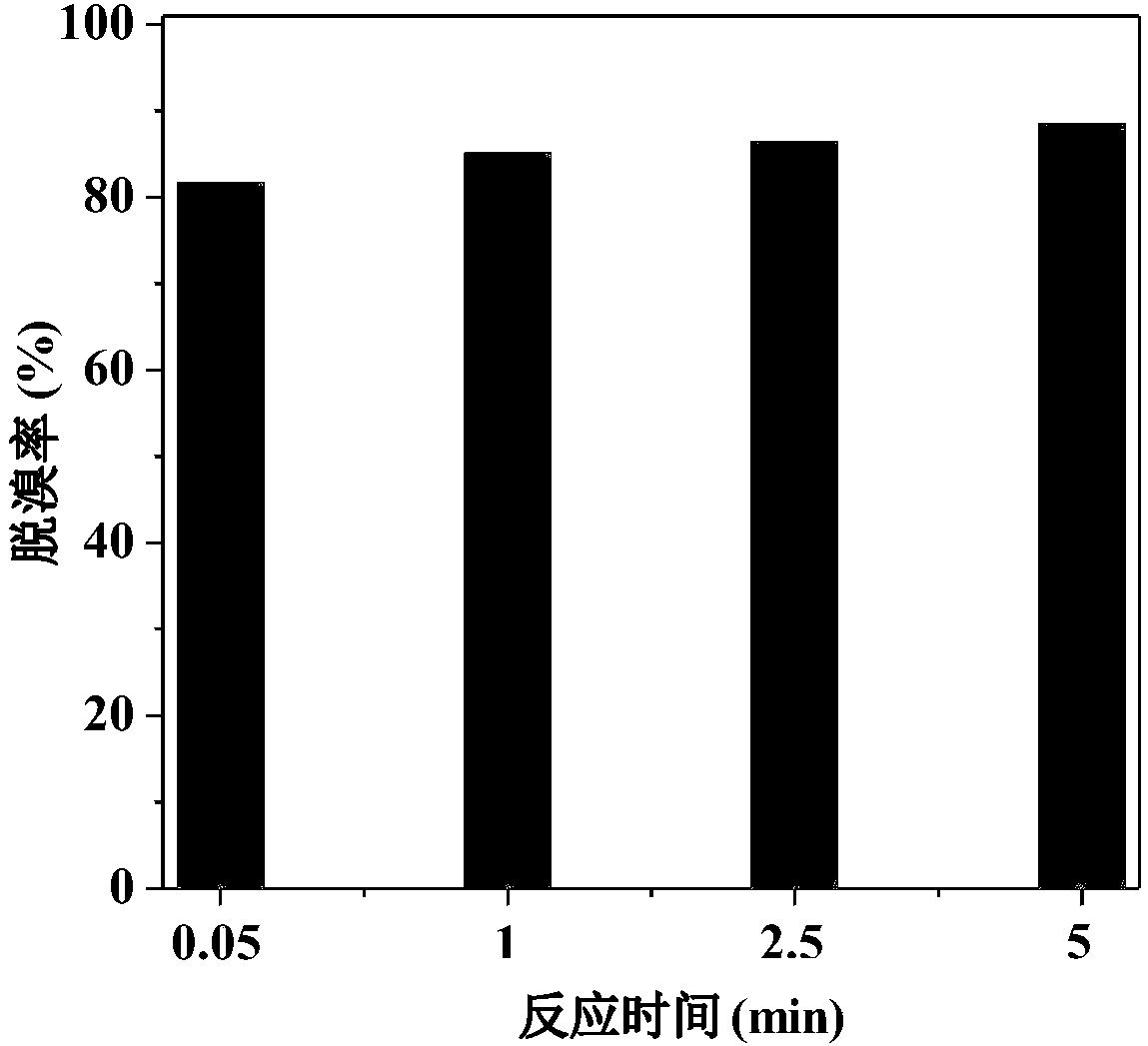

[0032] Step 2: Under stirring, quickly add hydrazine hydrate to the above-mentioned dispersion liquid and press the stopwatch at the same time to start timing. The final concentration of hydrazine hydrate added is 200mmol L-1 , when the reaction time is 3s, 15s, 30s, 1min, 2.5min, 5min, draw a certain amount of reaction solution with a syringe and quickly pass through a 0....

Embodiment 2

[0037] Example 2 A high-efficiency deep chemical reduction debromination treatment method for polybrominated diphenyl ethers, some adjustments are made on the basis of steps 1 and 2 of Example 1:

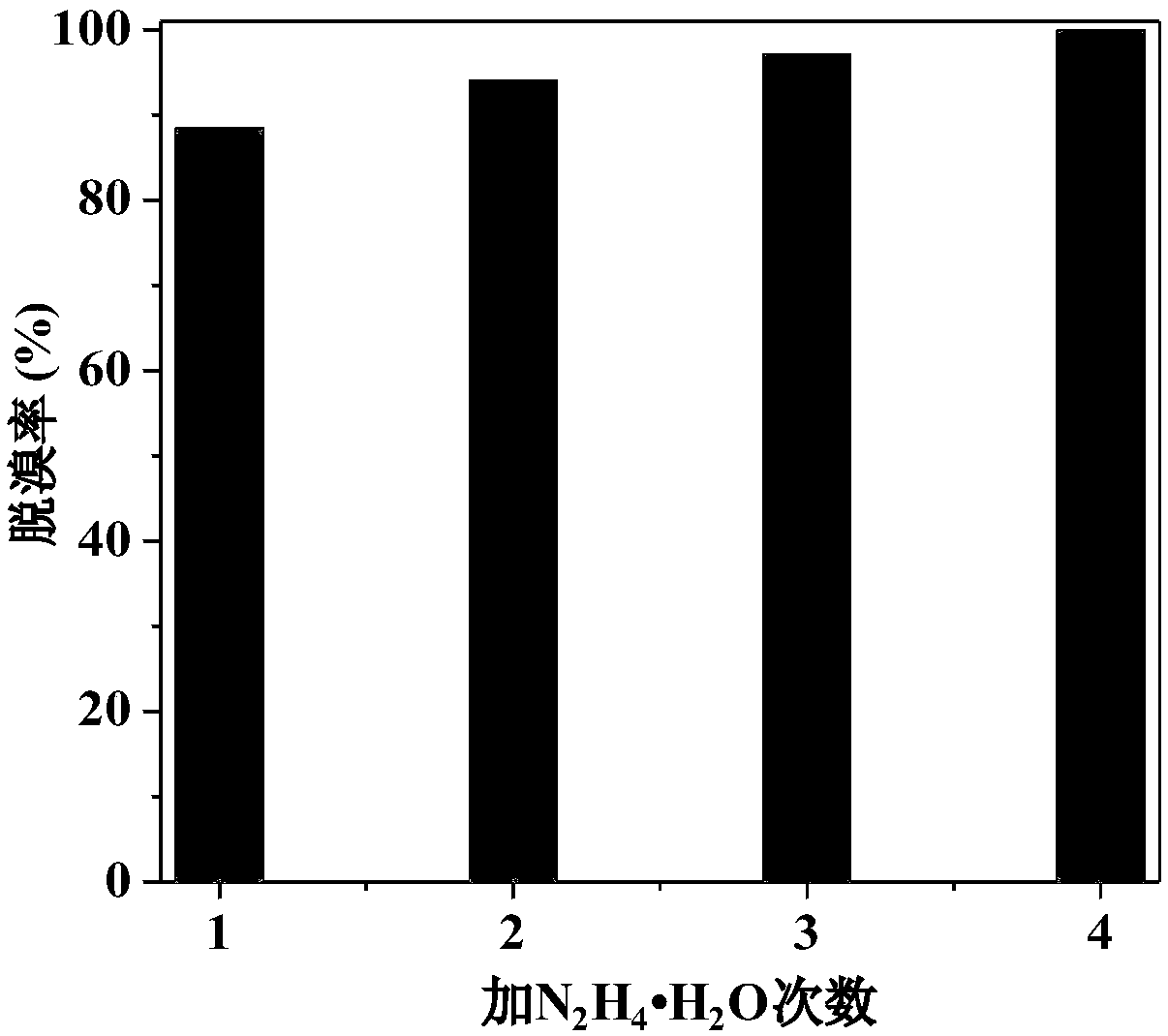

[0038] What is different from Example 1 is: after reacting 5min in the step 2, add the same amount of hydrazine hydrate with the first addition in the dispersion liquid, continue to react after 5min and then add the same amount of hydrazine hydrate with the first addition, so a total of Add three times, get certain reaction solution after adding hydrazine hydrate 5min each time, obtain the reaction solution of four stages thus, get supernatant after rapid filtration, adopt the method in embodiment 1 test 2 to measure its bromide ion concentration respectively , so as to calculate the debromination rate, the obtained results are as follows image 3 shown. image 3 It shows that BDE47 can be completely debrominated by increasing the amount of hydrogen donor hydrazine hydrate step by ...

Embodiment 3

[0039] Example 3 A high-efficiency deep chemical reduction debromination treatment method for polybrominated diphenyl ethers, some adjustments are made on the basis of Example 2:

[0040] The difference from Example 2 is: Step 1: Weigh 10 mg of Cu / TiO in Example 1 2 Put the catalyst in a beaker, add 50mL, 1500mg·L -1 BDE47 methanol solution (prepared by dissolving solid BDE47 in methanol) and ultrasonically disperse evenly. In step 2, the number of times of adding hydrazine hydrate is increased to five times, and the reaction solution of six stages of reaction is collected, and the supernatant is obtained after rapid filtration, and then the method in Example 1 Test 2 is used to measure the bromide ion concentration, thereby calculating the debromination rate, the result is Figure 4 shown. Figure 4 showed that when the initial concentration of BDE47 was as high as 1500mg·L -1 When hydrazine hydrate is added, the added BDE47 can still be rapidly and deeply debrominated. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com