High temperature exhaust gas dust removal method

A technology of high temperature waste gas and dust removal tower, applied in the field of flue gas treatment, can solve problems such as poor dust removal effect and air pollution, and achieve the effect of improving dust removal effect, saving water resources and avoiding accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described in detail below by the specific embodiment:

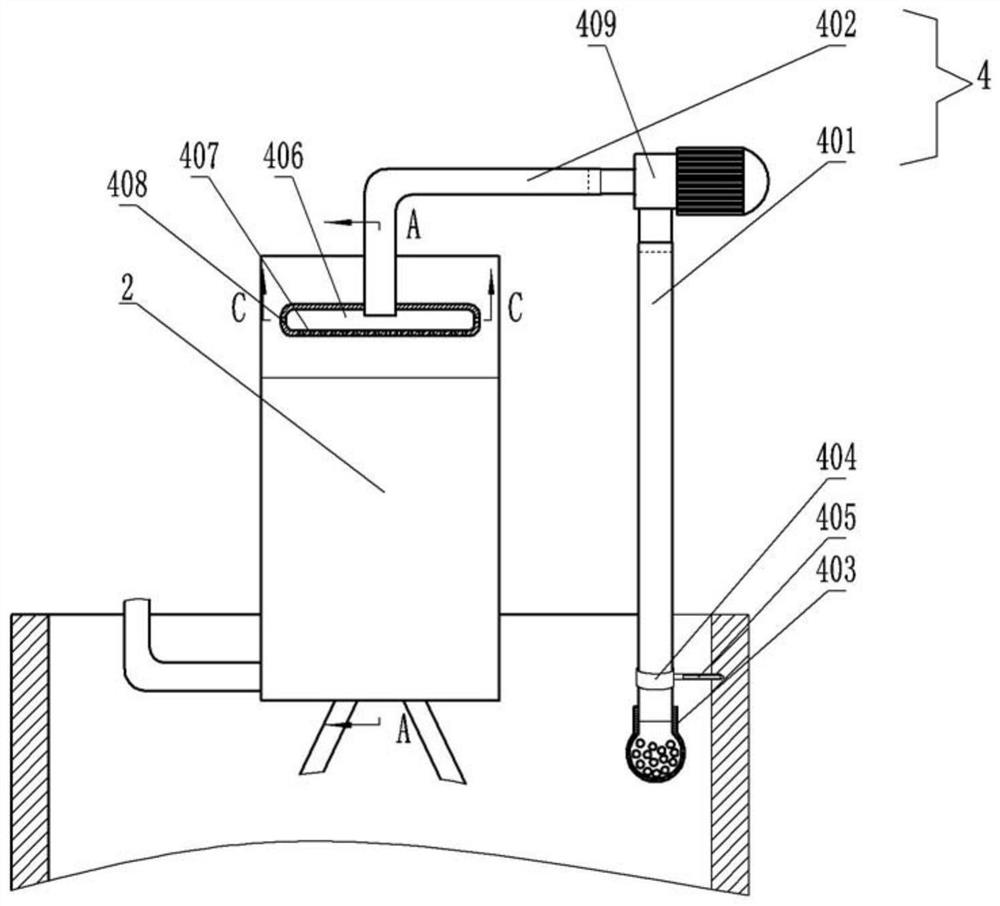

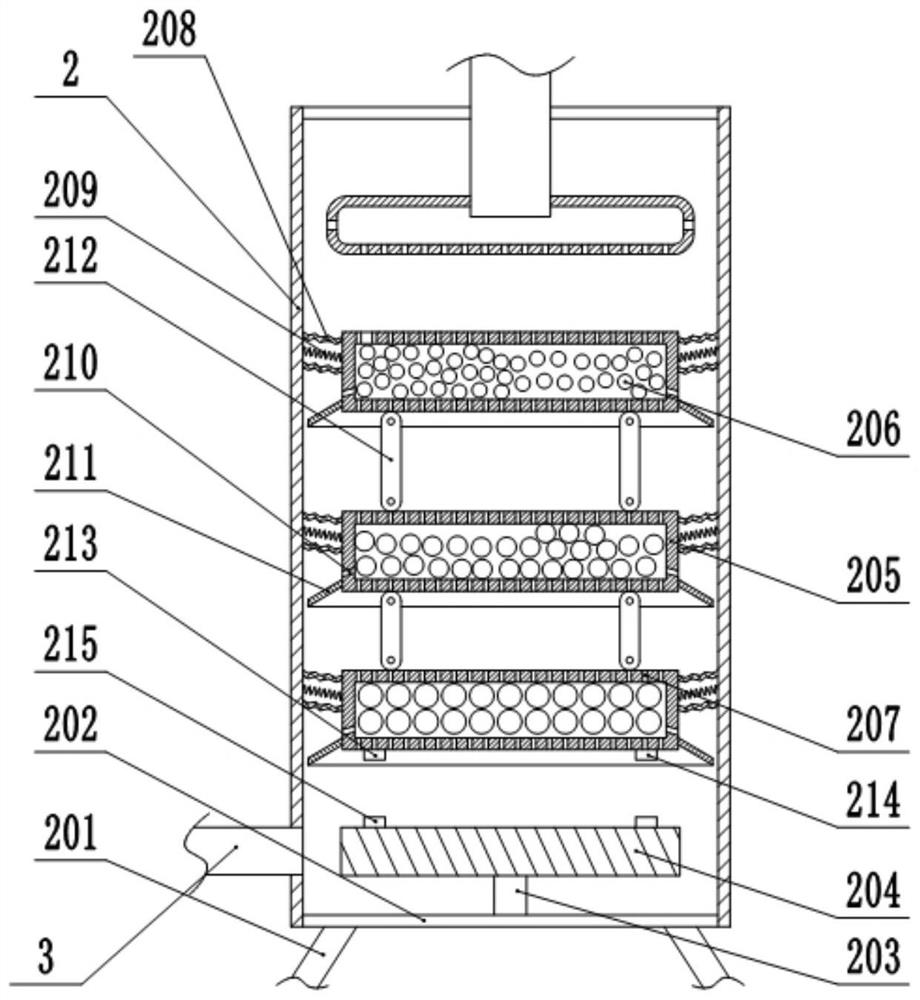

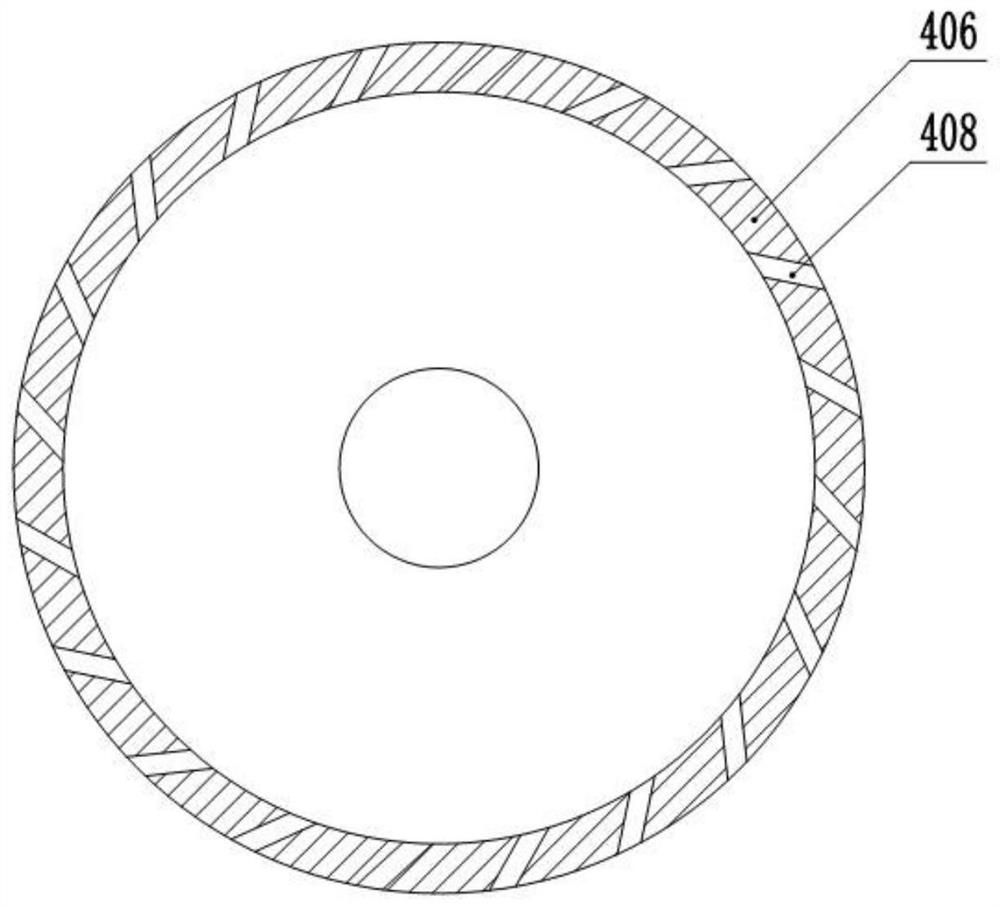

[0028]Reference numerals in the accompanying drawings include: dust cartridge 2, leg 201, horizontal axis 202, vertical axis 203, turbine 204, filter disc 205, steel ball 206, filter hole 207, annular airbag 208, support spring 209, drainage The hole 210, the guide plate 211, the pull rod 212, the first magnet 213, the second magnet 214, the magnetic block 215, the exhaust pipe 3, the circulation tube 4, the water pipe 401, the water pipe 402, the filter ball 403, the positioning ring 404, Screw 405, water spray disk 406, first water hole 407, second water hole 408, pump 409, outer cavity 71, upper portion 721, lower portion 722, inner cavity 72, blade 73, strip hole 731, telescopic rod 732 , The compression spring 733, the screw 74, the stirred leaf 75, the one-way bearing 76.

[0029]The high temperature exhaust gas dust removal method of this embodiment includes the steps of:

[0030]Step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com