Method for preparing sodium metatitantate-potassium tetratitanate composite catalytic material by molten salt method

A technology of potassium tetratitanate and sodium metatitanate, applied in chemical instruments and methods, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc., can solve the problems of high yield, high cost, and danger. , to achieve the effect of excellent catalytic performance, low cost and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Example: Slowly mix 5ml of acetic acid solution with 2ml of tetrabutyl titanate under stirring, continue to stir for 30 minutes, carry out hydrothermal reaction at 150°C for 24h, and vacuum-dry the sample after centrifugation at 60°C to obtain TiO 2 Precursor samples.

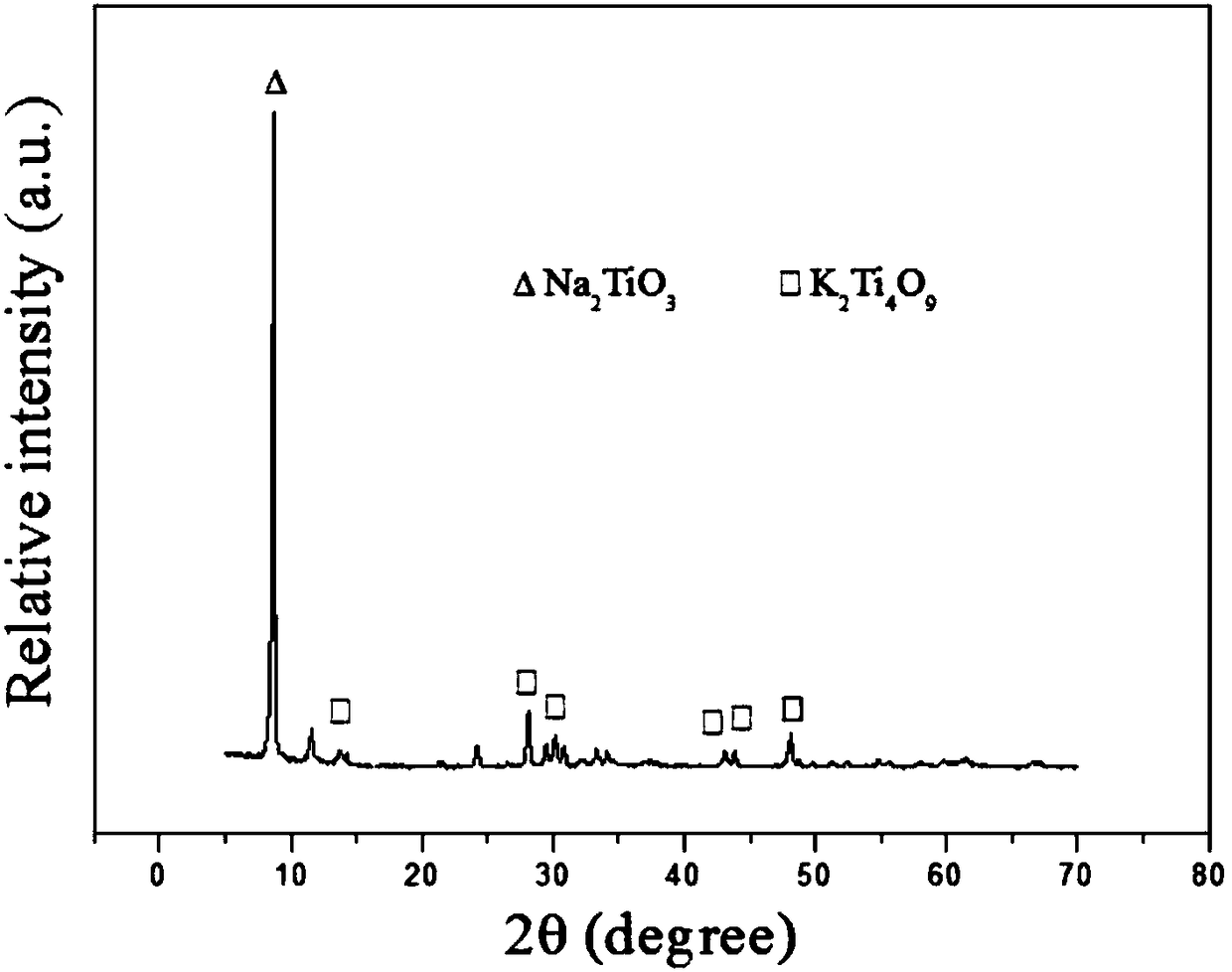

[0040] Then TiO2 Precursor sample, NaNO 3 and KNO 3 Mix evenly at a mass ratio of 5:1:1, calcinate at 350°C for 4 hours, wash and dry thoroughly, and then the composite catalytic material of sodium metatitanate-potassium tetratitanate can be obtained.

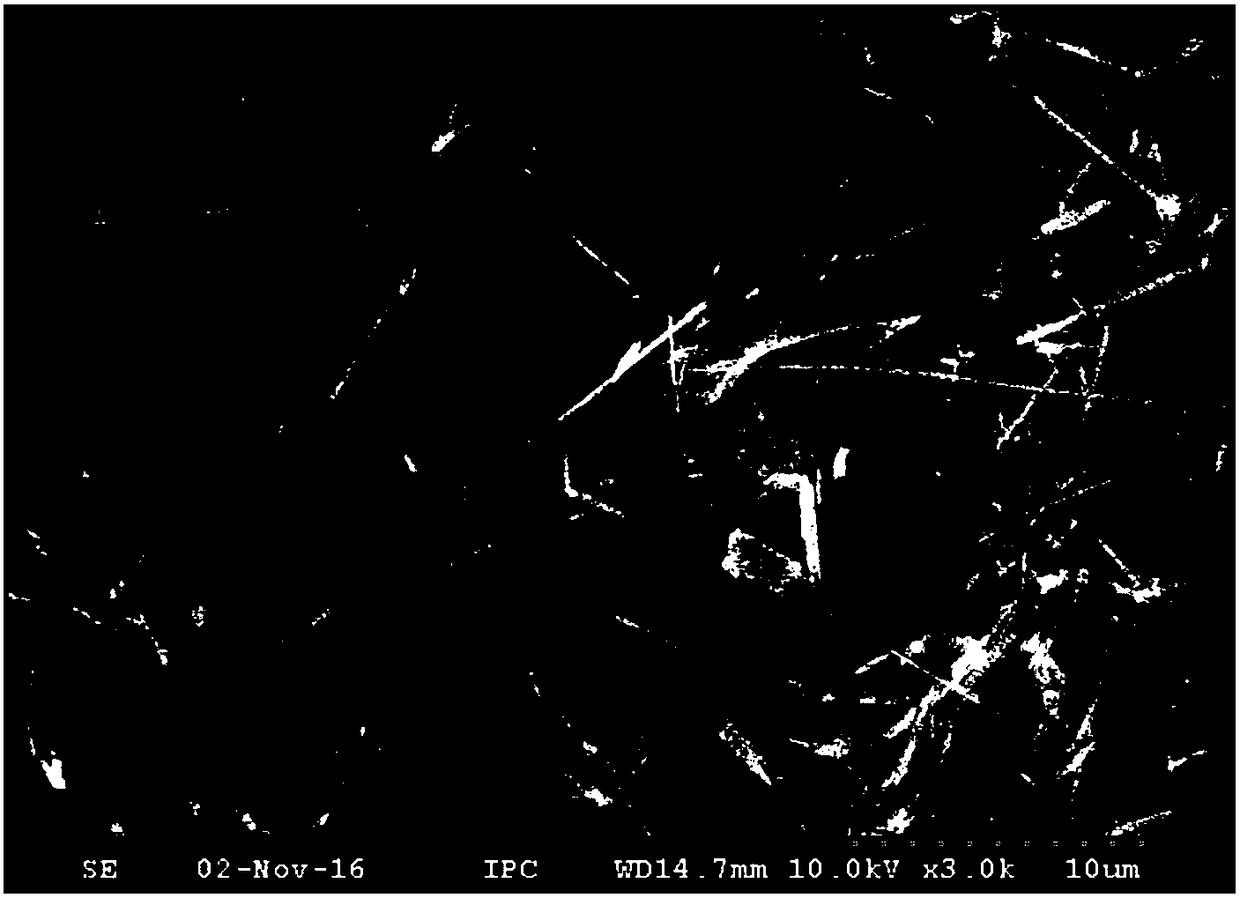

[0041] Prepared sodium metatitanate-potassium tetratitanate composite catalytic material (see figure 1 ), which is nanoribbon-shaped, with smooth surface and clear edges and corners, with a length of about 6-13 microns and a width of about 200 nanometers (see figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com