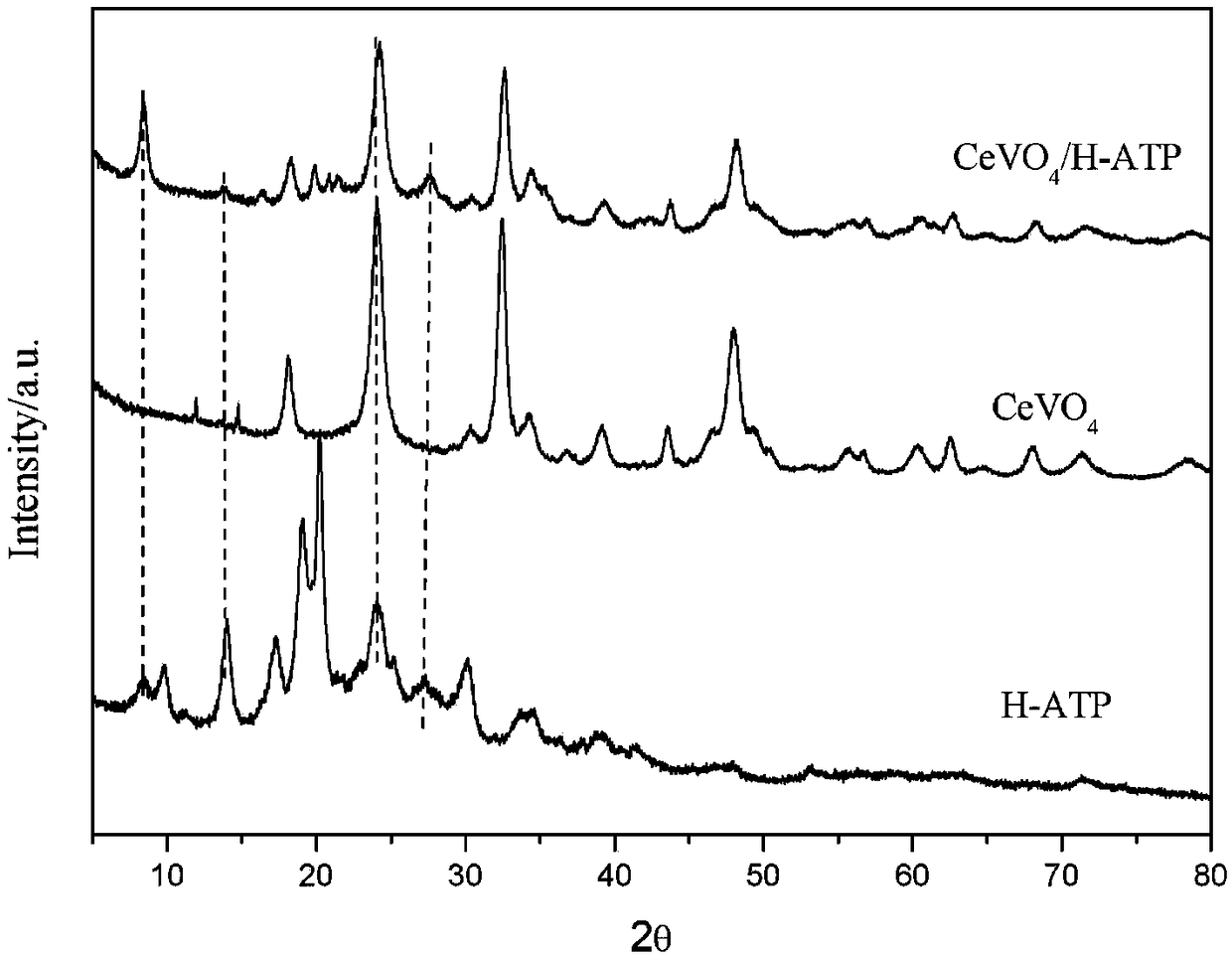

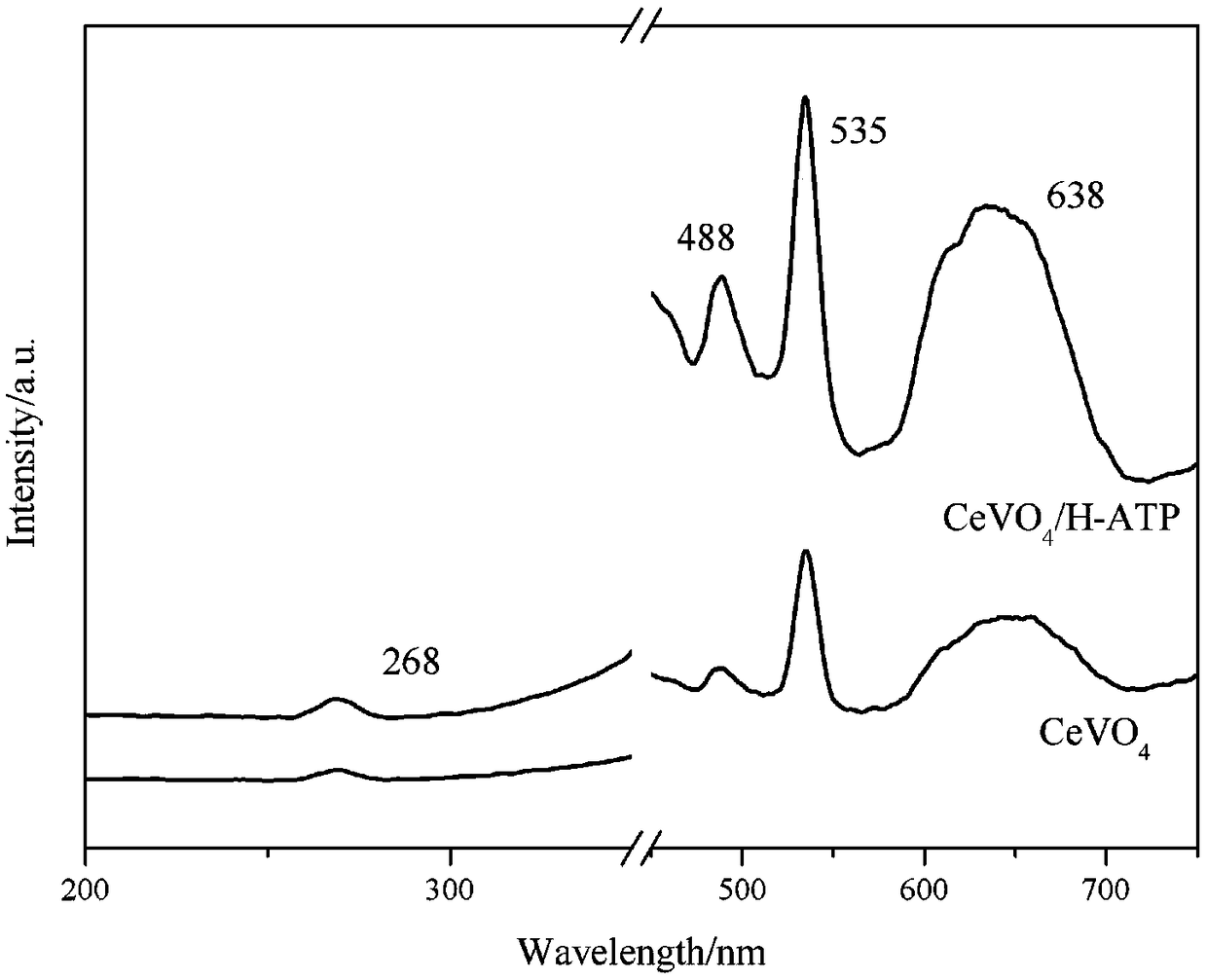

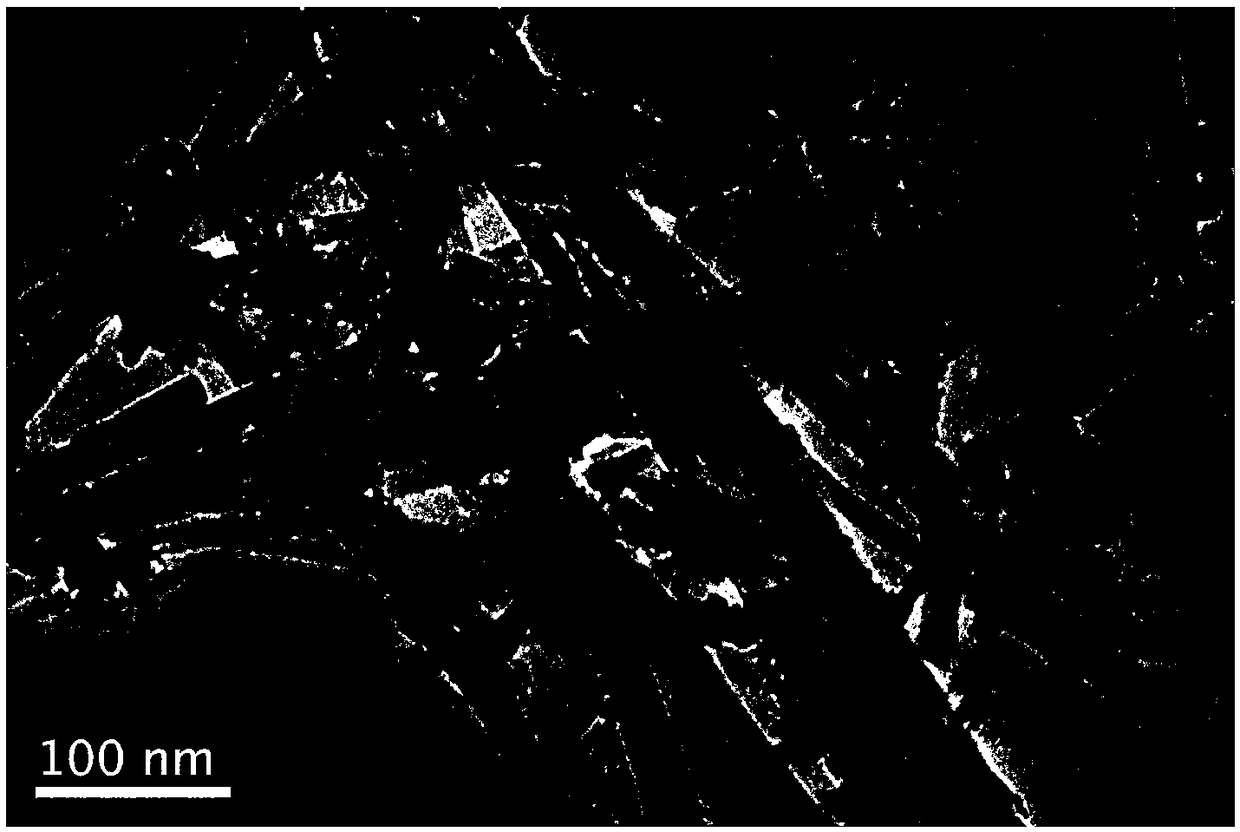

Preparation method and application of cerium vanadate/modified attapulgite up-conversion heterojunction photocatalyst

The technology of attapulgite and photocatalyst is applied in the application field of photocatalytic degradation of styrene, which can solve the problems of low light absorption and utilization efficiency of photocatalyst, and achieve the effects of improving photocatalytic performance, improving utilization rate and improving reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, weigh 2g of purified attapulgite and dissolve it in 100mL of phosphoric acid solution with a mass fraction of 30%. After ultrasonic dispersion, place it in a water bath, treat it at 70°C for 10 hours, and filter it with a circulating vacuum pump. The filter cake is fully washed with water. , dried at 60°C for 16 hours to obtain a modified attapulgite product; mix 0.73g EDTA with 0.86g Ce(NO 3 ) 3 After mixing evenly, add water to fully dissolve to obtain a solution, add 0.23g NH 4 VO 3 To the above solution, use 1M ammonia solution to adjust the pH to 10, then add 1 g of modified attapulgite to the above mixture, and stir until it is evenly mixed to obtain a mixture; finally transfer the above mixture to a 100mL reaction kettle, place In a microwave hydrothermal chemical reaction apparatus, react at 160°C for 1h, cool, centrifuge, wash after the reaction, dry at 80°C, and finally grind to obtain CeVO with a loading capacity of 50%. 4 / H-ATP composite.

[0026...

Embodiment 2

[0032] First, weigh 2g of purified attapulgite and dissolve it in 100mL of phosphoric acid solution with a mass fraction of 30%. After ultrasonic dispersion, place it in a water bath, treat it at 70°C for 10 hours, and filter it with a circulating vacuum pump. The filter cake is fully washed with water. , and dried at 60°C for 16 hours to obtain the acid-modified attapulgite product; mix 0.44g EDTA with 0.52g Ce(NO 3 ) 3 After mixing evenly, add water to fully dissolve to obtain a solution, add 0.14g NH 4 VO 3 to the above solution, adjust the pH to 9 with 1M ammonia solution, then add 1 g of modified attapulgite into the above mixture, and stir until it is evenly mixed to obtain a mixture; finally, transfer the mixture to a 100mL reaction kettle and place In a microwave hydrothermal chemical reaction apparatus, react at 170°C for 1.5h. After the reaction is completed, cool, centrifuge, wash, dry at 60°C, and finally grind to obtain CeVO with a loading capacity of 30%. 4 / H...

Embodiment 3

[0034] First, weigh 2g of purified attapulgite and dissolve it in 100mL of phosphoric acid solution with a mass fraction of 30%. After ultrasonic dispersion, place it in a water bath, treat it at 70°C for 10 hours, and filter it with a circulating vacuum pump. The filter cake is fully washed with water. , dried at 60°C for 16 hours to obtain the acid-modified attapulgite product; mix 0.29g EDTA with 0.35g Ce(NO 3 ) 3 After mixing evenly, add water to fully dissolve to obtain a solution, add 0.09g NH 4 VO 3 To the above solution, use 1M ammonia solution to adjust the pH to 8, then add 1g of modified attapulgite to the above mixture, stir well until the mixture is uniform, and obtain the mixture; finally transfer the mixture to a 100mL reaction kettle, place In a microwave hydrothermal chemical reaction apparatus, react at 170°C for 1.5h. After the reaction, cool, centrifuge, wash, dry at 90°C, and finally grind to obtain CeVO with a loading capacity of 20%. 4 / H-ATP composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com