Magnesium hydride/metal phthalocyanine hydrogen storage composite material and preparation method thereof

A technology of metal phthalocyanine and composite materials, applied in chemical instruments and methods, non-metallic elements, hydrogen, etc., to achieve the effects of convenient operation, improved hydrogen release performance, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) MgH with a purity of 98% by weight is fully dried 2 Add 10wt% fully dried NiPc powder with a purity of 95wt% to the powder, and add the above mixed powder and 30g of stainless steel balls with a diameter of 10mm into a ball mill jar.

[0029] (2) Ball mill the powder in (1) for 2 hours at a speed of 1000r / min, and stop for 15 minutes every 1 hour of ball milling. After getting MgH 2 / 10wt% NiPc hydrogen storage composite.

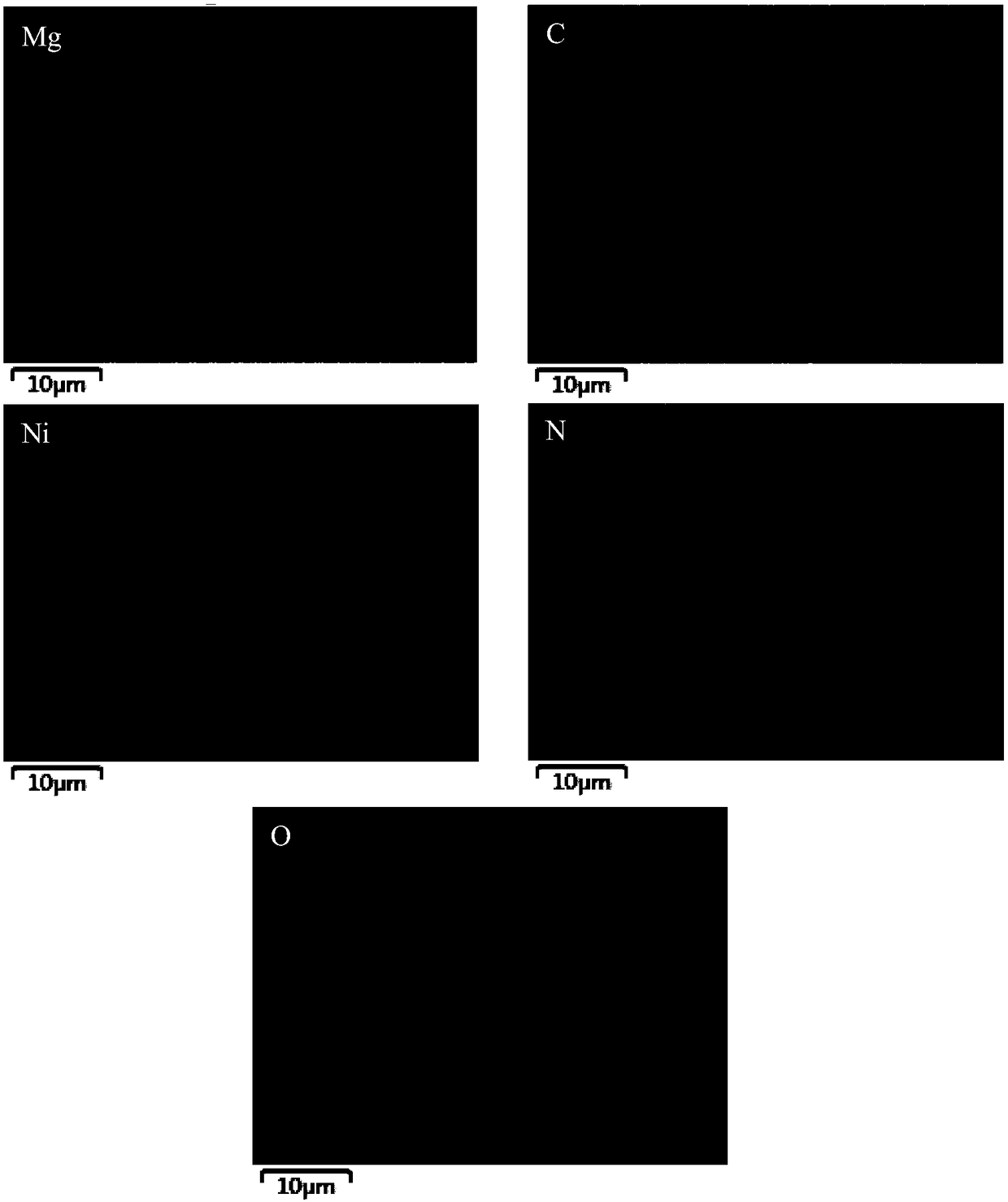

[0030] (3) For the convenience of comparison, the same process was used to prepare pure MgH 2 Ball milling system, X-ray diffraction (XRD), scanning electron microscopy (SEM), differential scanning calorimetry (DSC) characterization and comparison of the above two materials. and scanning electron microscopy-energy dispersive spectroscopy (SEM-EDS) for the 2 / 10wt% NiPc system for qualitative and quantitative analysis of elements.

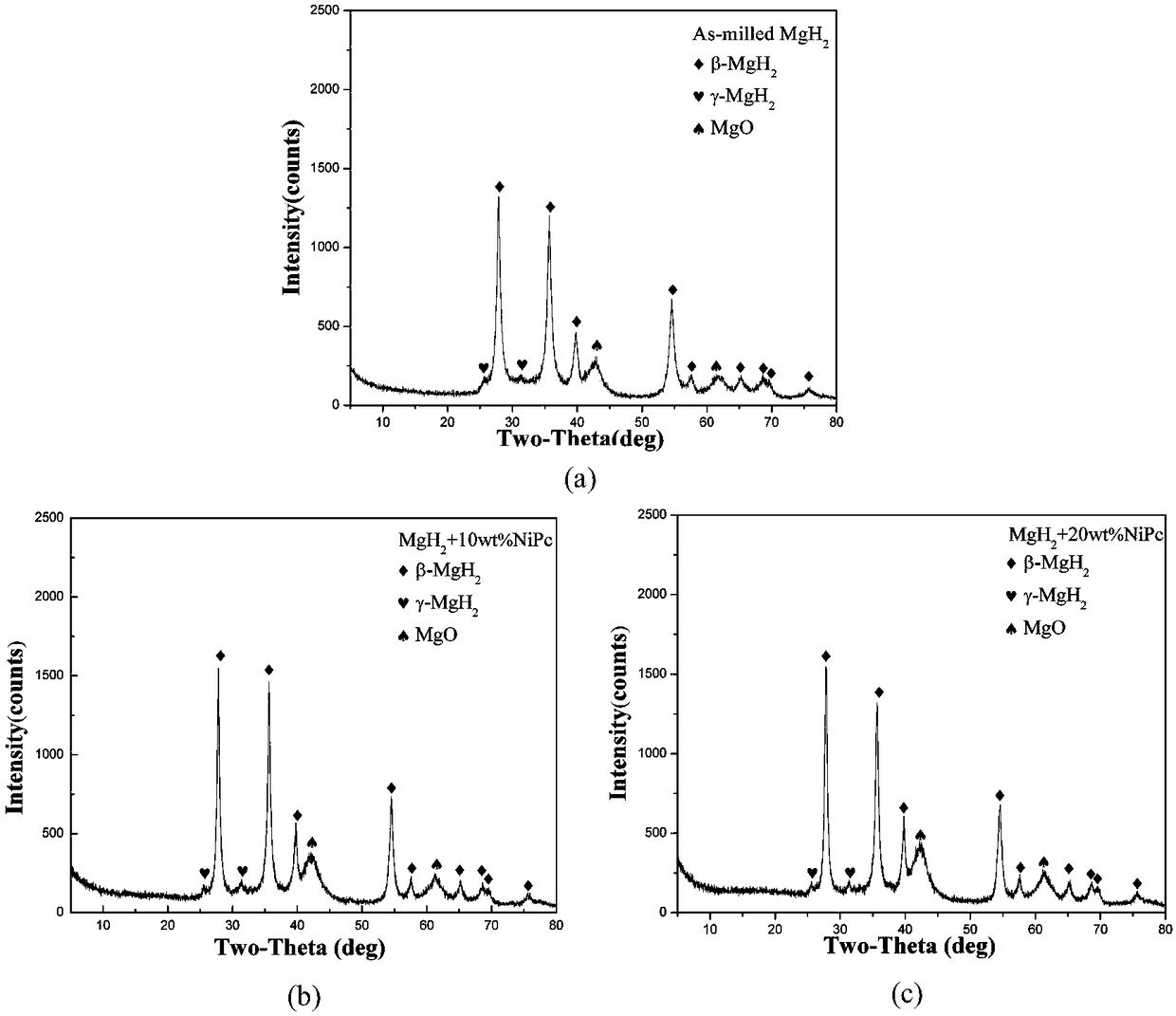

[0031] The sample prepared in the above process is MgH 2 / 10wt% NiPc hydrogen storage composite. Such as fig...

Embodiment 2

[0033] (1) to fully dry MgH 2 Add 20wt% fully dried NiPc powder to the powder, add the above mixed powder and 30g of stainless steel balls with a diameter of 10mm into the ball mill jar.

[0034] (2) Ball mill the powder in (1) for 2 hours at a speed of 1000r / min, and stop for 15 minutes every 1 hour of ball milling. After getting MgH 2 / 20wt% NiPc hydrogen storage composite material.

[0035] (3) to MgH 2 The / 20wt% NiPc hydrogen storage composite material was characterized by X-ray diffraction (XRD), scanning electron microscope (SEM), differential scanning calorimetry (DSC) and compared with the two materials in Example 1.

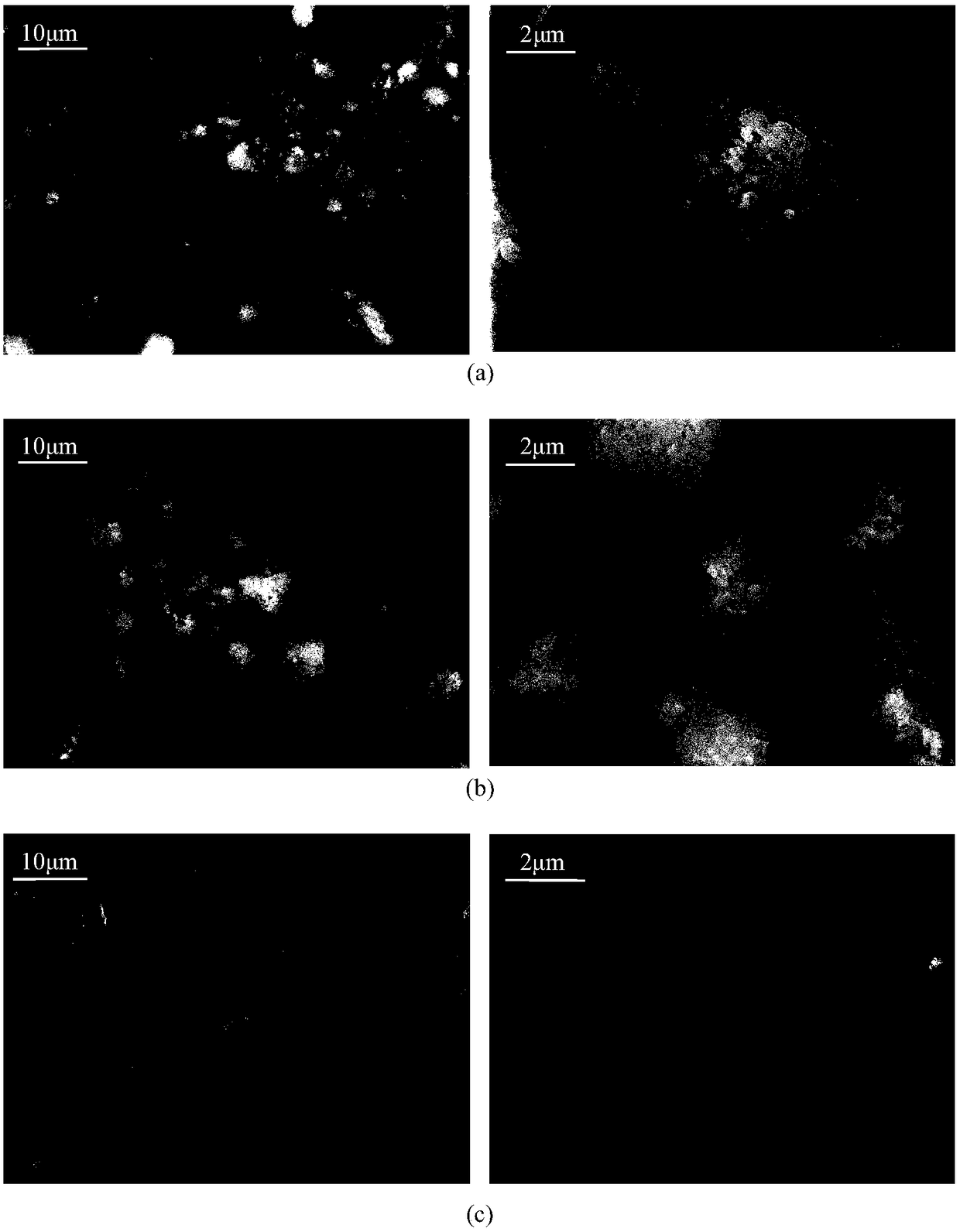

[0036] Depend on figure 1 (c) It can be seen that MgH 2 / 20wt% NiPc system XRD patterns and MgH 2 / 10wt% NiPc system is basically the same. Depend on figure 2 (c) It can be seen that MgH 2 / 20wt% NiPc system particles compared to pure MgH 2 The system has increased, and MgH 2 / 10wt% NiPc system compared with no significant change. This show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com