Hydrophobic nano silicon dioxide aerogel aqueous slurry

A nano-silica, hydrophobic technology, applied in the direction of filling slurry, epoxy resin coating, coating, etc., can solve the problems of high thermal conductivity, flammability, high water absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

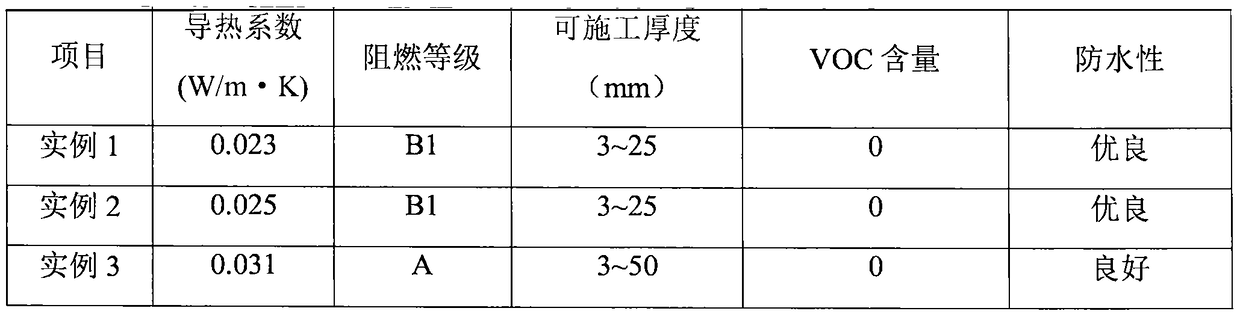

Examples

example 1

[0010] The raw materials and components of each component are as follows:

[0011] A component B component

[0012] Hydrophobic silica airgel: 15 parts Waterborne polyurethane resin: 30 parts

[0013] Industrial tap water: 65 parts

[0014] Wetting and dispersing agent: 0.5 parts

[0015] Aminosilane coupling agent: 1 part

[0016] Silicone water repellent: 1.5 parts

[0017] Hydroxyethylcellulose: 0.5 parts

[0018] Hollow glass microspheres: 20 parts

[0019] The preparation process of thermal insulation coating is as follows:

[0020] a. Add industrial tap water, wetting and dispersing agent, aminosilane coupling agent, water repellent, hydroxyethyl cellulose and hollow glass microspheres into a wide-mouth container with airtight function, and start the high-speed dispersing machine to disperse at 500RPM 5min, then close the disperser and add nano-hydrophobic silica airgel powder. After the addition is completed, close the stirring container, start the high-speed dis...

example 2

[0023] The raw materials and components of each component are as follows:

[0024] A component B component

[0025] Hydrophobic silica airgel: 20 parts Water-based epoxy resin: 30 parts

[0026] Industrial tap water: 65 parts Water-based epoxy resin curing agent: 10 parts

[0027] Wetting and dispersing agent: 0.5 parts

[0028] Aminosilane coupling agent: 1 part

[0029] Silicone water repellent: 1.5 parts

[0030] Hydroxyethylcellulose: 0.5 parts

[0031] Hollow glass microspheres: 15 parts

[0032] The preparation process of thermal insulation coating is as follows:

[0033] a. Add industrial tap water, wetting and dispersing agent, aminosilane coupling agent, water repellent, hydroxyethyl cellulose and hollow glass microspheres into a wide-mouth container with airtight function, and start the high-speed dispersing machine to disperse at 500RPM 5min, then close the disperser and add nano-hydrophobic silica airgel powder. After the addition is completed, close the sti...

example 3

[0036] The raw materials and components of each component are as follows:

[0037] A component B component

[0038] Hydrophobic silica airgel: 25 parts Ordinary Portland 42.5 cement: 50 parts

[0039] Industrial tap water: 65 parts Industrial tap water: 17.5 parts

[0040] Wetting and dispersing agent: 0.5 parts

[0041] Aminosilane coupling agent: 1 part

[0042] Silicone water repellent: 1.5 parts

[0043] Hydroxymethylcellulose: 0.5 parts

[0044] Hollow perlite vitrified microspheres: 10 parts

[0045] The preparation process of thermal insulation putty is as follows:

[0046] a. Add industrial tap water, wetting and dispersing agent, aminosilane coupling agent, water repellent, hydroxymethyl cellulose and hollow glass microspheres into a wide-mouth container with airtight function, and start the high-speed dispersing machine to disperse at 500RPM 5min, then close the disperser and add nano-hydrophobic silica airgel powder. After the addition is completed, close the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com