Method for producing high-octane-number gasoline from aromatic hydrocarbon raffinate oil

A high-octane gasoline and raffinate technology, applied in the field of hydrocarbon isomerization, can solve the problems of low ethylene yield and large waste gas output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

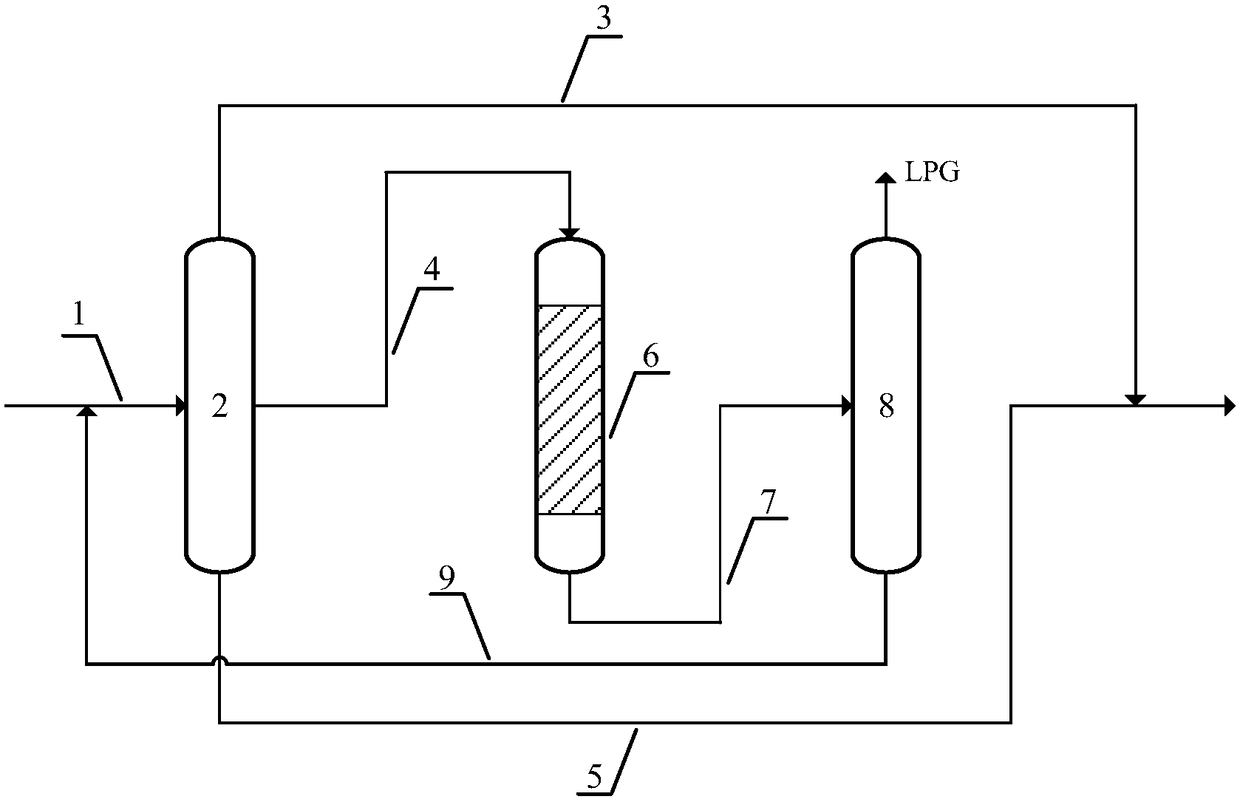

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the catalyst containing zeolite is as follows: molding a predetermined amount of zeolite and alumina to obtain a carrier. The molding method is preferably extrusion molding, and the carrier after molding is loaded with a Group VIII metal by a conventional method, such as an impregnation method, to obtain a catalyst.

[0026] The described solid superacid catalyst for isomerization comprises 0.05-2.0% by mass of Group VIII metal component and 98-99.95% by mass of zirconia carrier containing sulfate radicals, and the sulfur content in the catalyst is calculated by elemental sulfur 0.5-4.0% by mass.

[0027]Preferably, the solid superacid catalyst comprises 0.05 to 2.0% by mass of Group VIII metal components and 98 to 99.95% by mass of sulfate-containing mixed oxide supports, and the mixed oxide supports contain 50 to 70% by mass aluminum oxide and 30-50% by mass of zirconia, and the sulfur content in the solid superacid catalyst is 0.5-3.5% by ma...

example 1

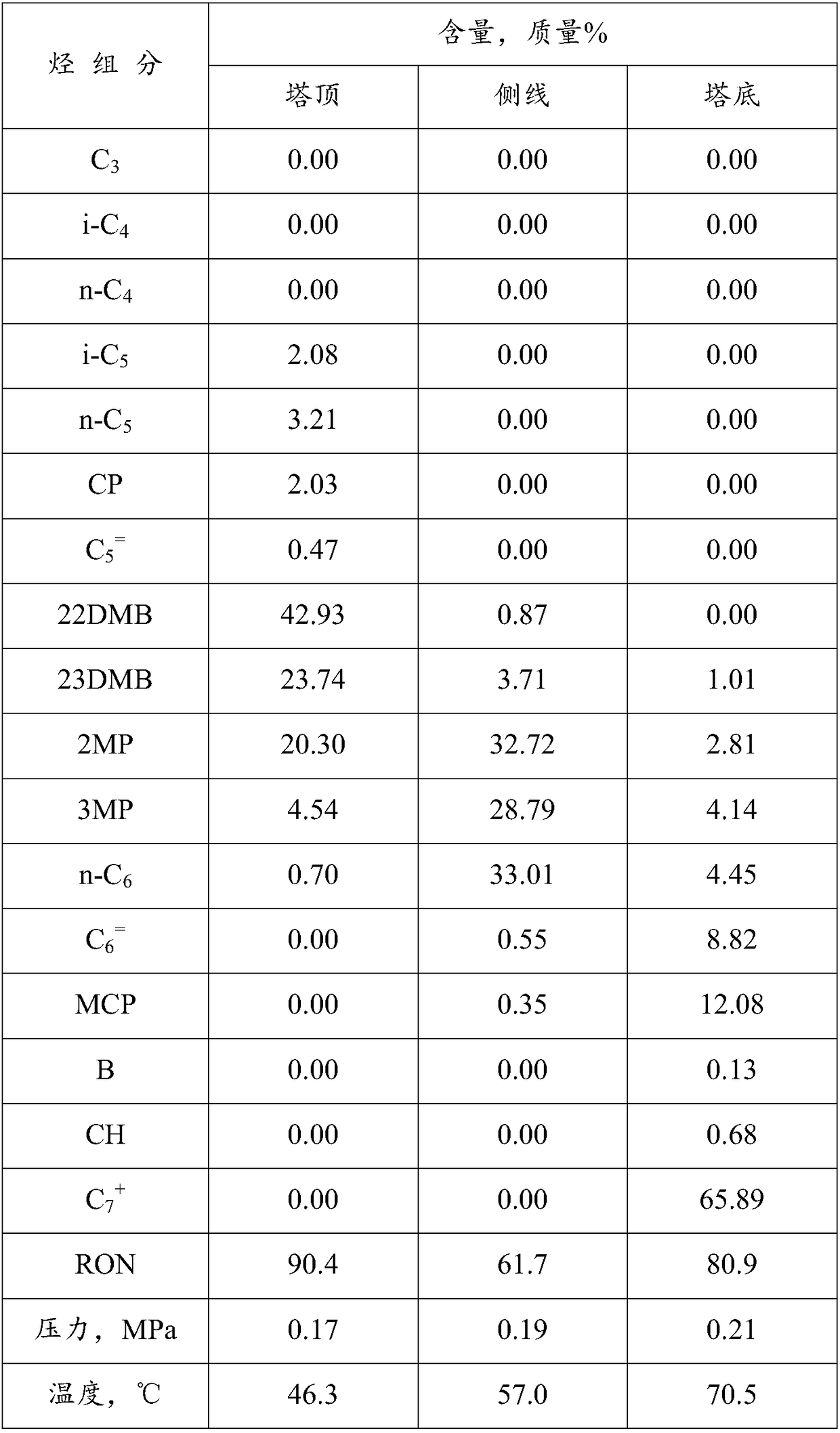

[0040] The benzene raffinate shown in Table 1 is sent to the deisohexane tower for rectification. The number of theoretical plates in the rectification tower is 63. The controlled operating pressure and temperature and the composition of the tower top, side stream and tower bottom fraction obtained are shown in the table 2.

[0041] Table 1

[0042] hydrocarbon component

Content, mass%

C 3

0.00

i-C 4

0.00

n-C 4

0.00

i-C 5

1.56

n-C 5

2.41

CP

1.52

C 5 =

0.35

22DMB

5.78

23DMB

4.99

2MP

22.32

3MP

16.89

n-C 6

22.73

C 6 =

2.92

MCP

2.84

B

0.03

CH

0.16

C 7 +

15.49

[0043] The meanings of the symbols in Table 1 are (the same below): C 3 —Propane, i-C 4 — Isobutane, n-C 4 — n-butane,

[0044] i-C 5 — Isopentane, n-C 5 -n-pentane, CP-cyclopentane, C 5 = —C 5 olefins,

[0045] 22DMB...

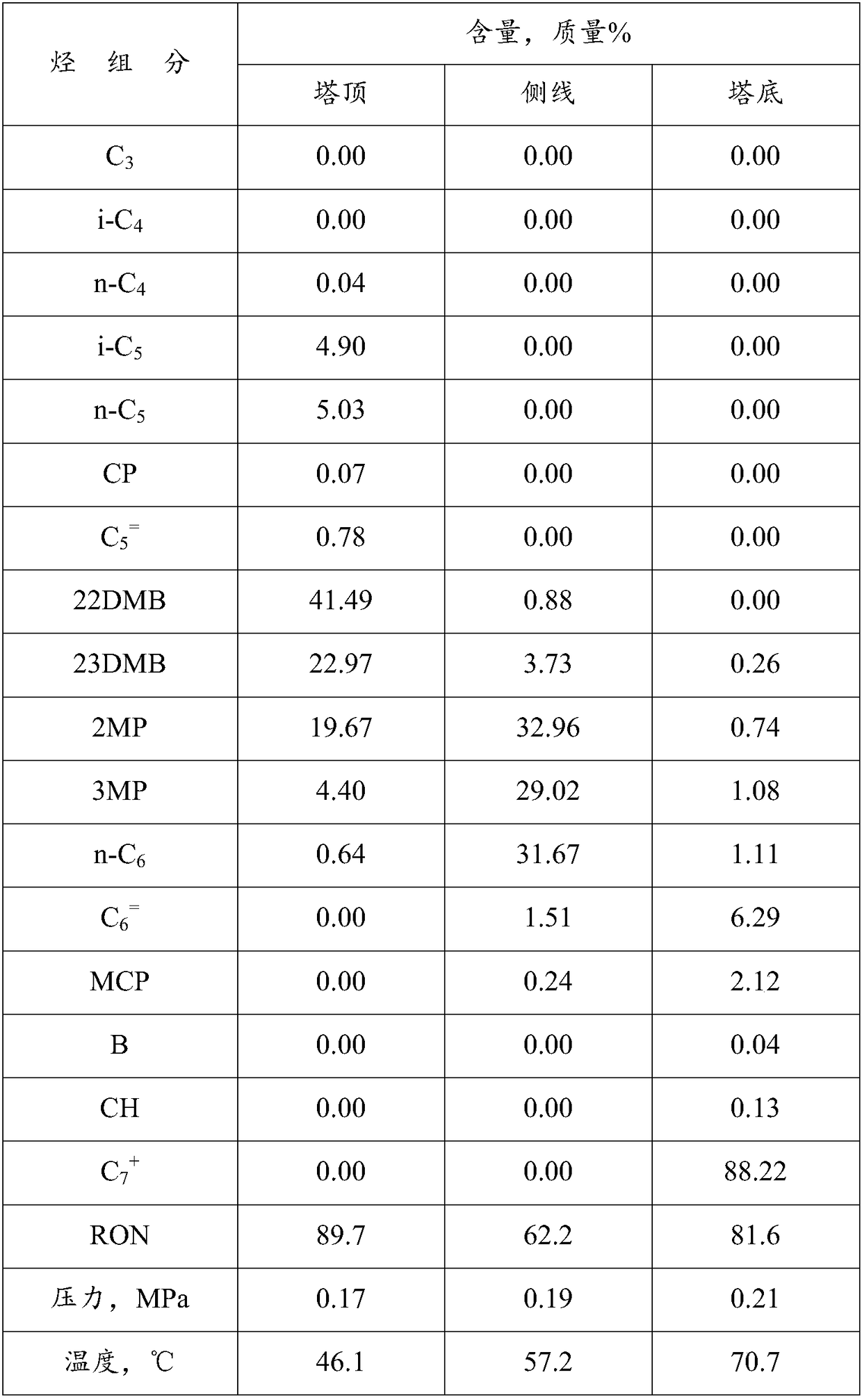

example 2

[0051] The benzene raffinate shown in Table 3 is sent to the deisohexane tower for rectification. The number of theoretical plates in the rectification tower is 71. The controlled operating pressure and temperature and the obtained tower top, side line and tower bottom compositions are shown in Table 4. .

[0052] table 3

[0053] hydrocarbon component

Content, mass%

C 3

0.00

i-C 4

0.00

n-C 4

0.02

i-C 5

2.25

n-C 5

2.31

CP

0.03

C 5 =

0.36

22DMB

3.47

23DMB

3.00

2MP

13.40

3MP

10.14

n-C 6

12.11

C 6 =

4.72

MCP

1.13

B

0.02

CH

0.07

C 7 +

46.97

[0054] Table 4

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com