Hot-wet air waste heat recovery process

A hot and humid air and waste heat recovery technology, which is applied in heat recovery systems, energy recovery systems using air flow as shielding, ventilation and heating, etc., can solve problems such as energy waste and environmental pollution, and achieve simple processes, low equipment investment and low cost. The effect of low operating cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

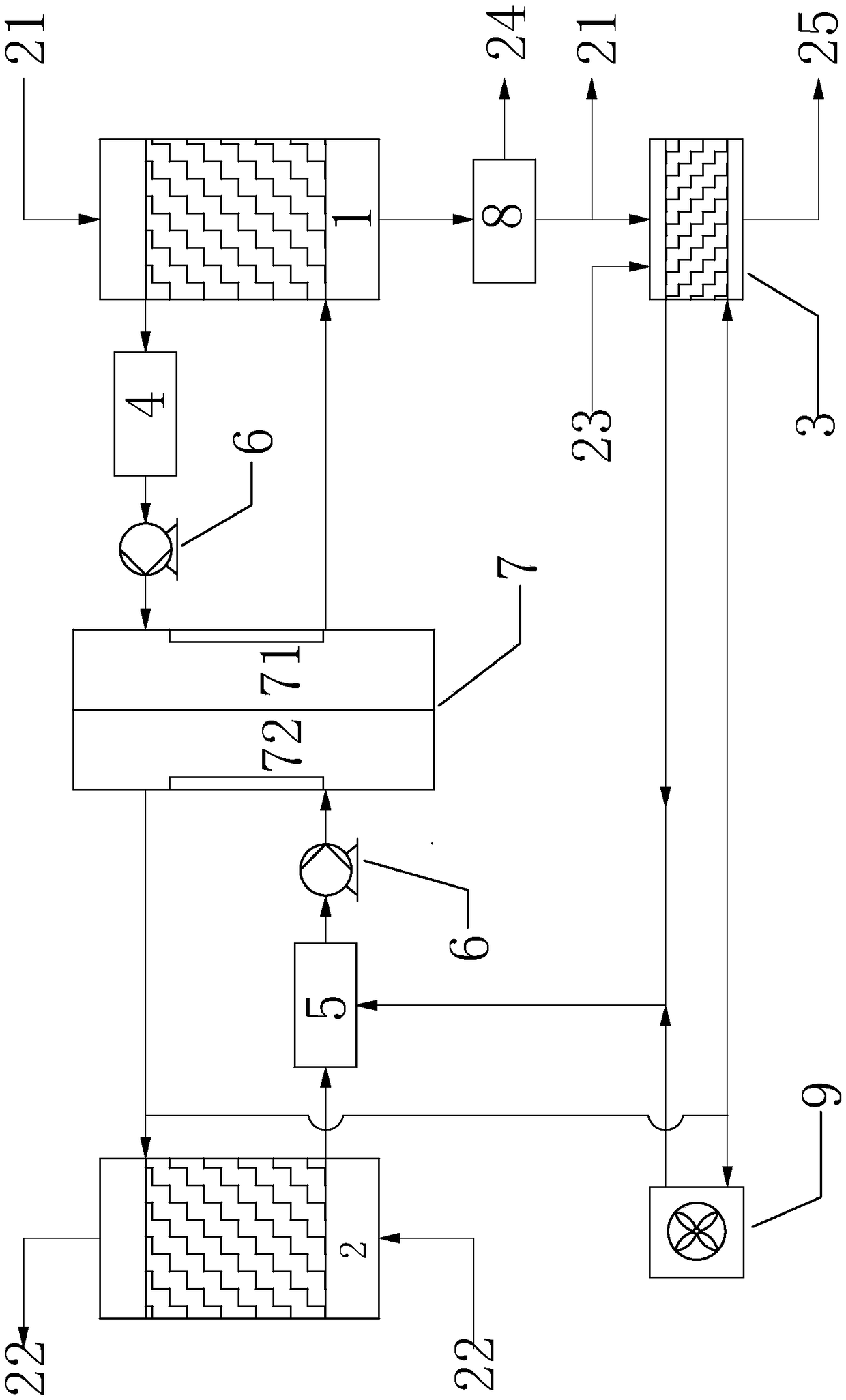

[0046] The hot and humid air 21 to be treated first enters the first heat exchanger 1, and cold water flows through the tubes of the first heat exchanger 1, and the hot and humid air 21 exchanges heat with the cold water. After cooling and dehumidification, the hot and humid air 21 passes through the defogging 8, the condensed water 24 generated is recycled, and then the hot and humid air 21 is directly discharged or preheated by the third heat exchanger 3 before entering the next process. Wherein the temperature of the hot and humid air 21 is 15-150° C., and the relative humidity is 10-100%.

[0047] In the first heat exchanger 1, the heat in the hot humid air 21 is transferred to the cold water, and the temperature of the cold water increases. The heated cold water is transported to the first buffer water tank 4 through the pipeline, and then transported to the cold water side 71 of the heat pump through the pump 6, the temperature of the cold water is lowered, and the heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com