Photosensitive compositions, hardening film, color filter and electronic device

A technology of photosensitive composition and compound, which is applied in optical filters, photosensitive materials for optomechanical equipment, instruments, etc. It can solve the problems of reduced residual film rate, reduced transmittance of hardened film, and aggregation of inorganic particles, and achieves The effect of excellent refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0201] Next, the present invention will be specifically described by way of synthesis examples, reference examples, examples, and comparative examples, but the present invention is not limited by these examples.

[0202] About the abbreviation of each component in Table 1 to Table 2,

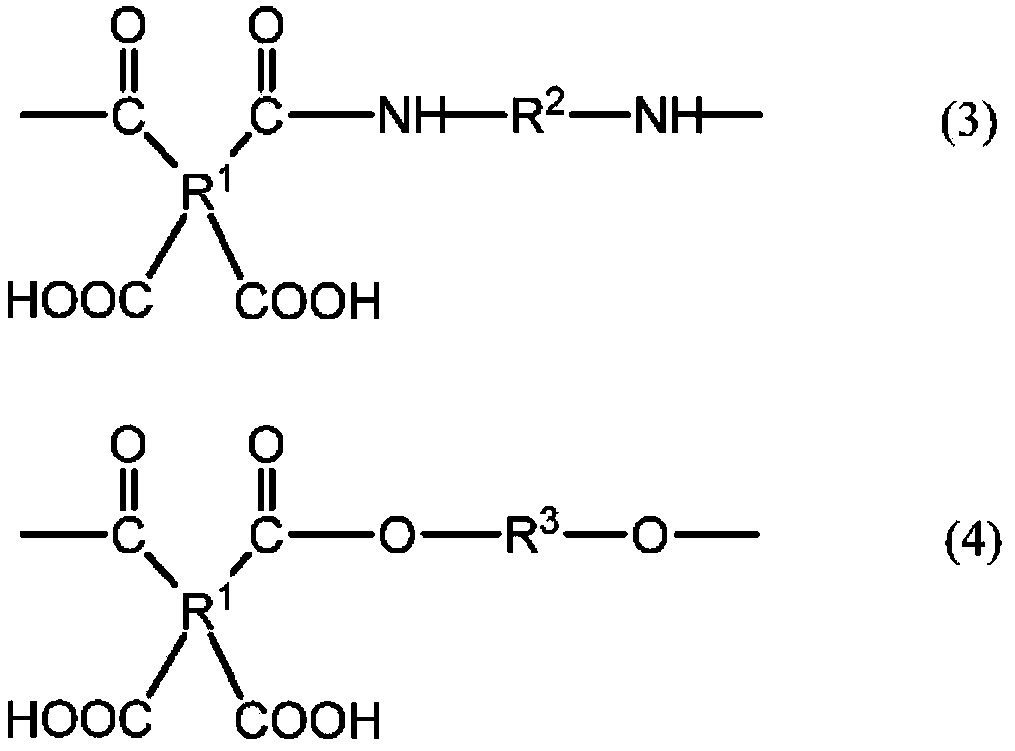

[0203] ODPA is 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride,

[0204] BT-100 is 1,2,3,4-butane tetracarboxylic dianhydride,

[0205] SMA1000P is styrene-maleic anhydride copolymer (trade name; Chuanyuan Chemical Co., Ltd.),

[0206] MEHQ is 4-methoxyphenol (hydroquinone monomethyl ether),

[0207] Epoxy Ester (Epoxy Ester) 70PA is an acrylic modified product of propylene glycol diglycidyl ether (trade name; Gongrongshe Chemical Co., Ltd.),

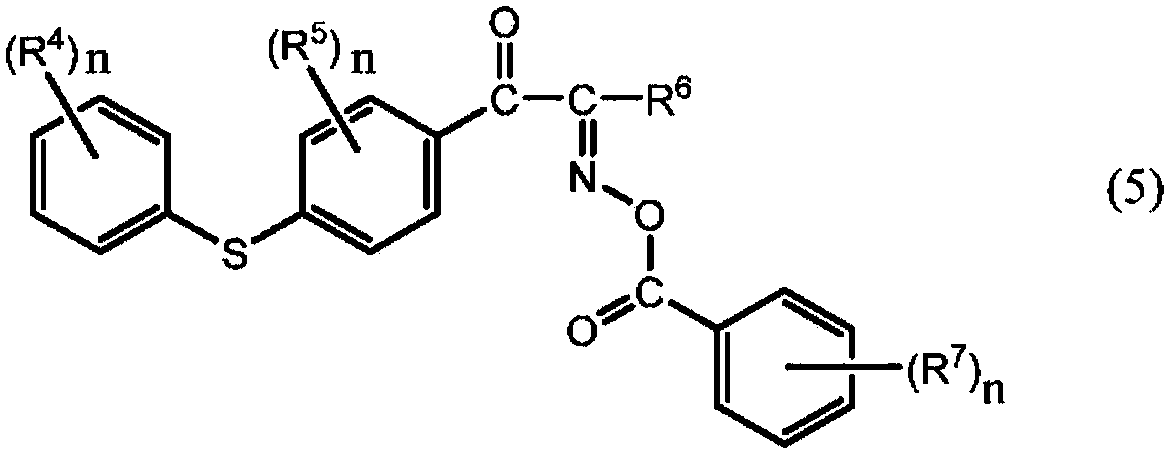

[0208] DDS is 3,3'-diaminodiphenyl sulfone,

[0209] M-520 is a compound having a polymerizable double bond, Aronix (Aronix) M-520 (trade name; Toagosei Co., Ltd.),

[0210] NCI-930 is photopolymerization initiator Adeka arc Luz (Adeka arc Luz) ...

Synthetic example 1

[0220] [Synthesis Example 1] Synthesis of Polyester Amic Acid (A1) Solution

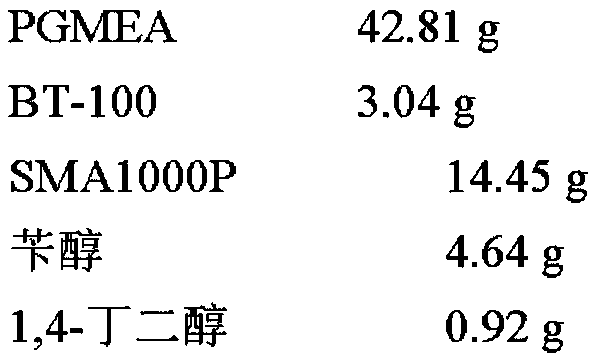

[0221] In a four-necked flask with a stirrer, dehydrated and purified PGMEA, BT-100, SMA1000P, benzyl alcohol, and 1,4-butanediol were sequentially loaded with the following weights, and carried out under dry nitrogen flow at 125°C for 3 Stir for an hour.

[0222]

[0223] Then, the reaction liquid was cooled to 25 degreeC, DDS and PGMEA were thrown in by the following weight, and after stirring at 20 degreeC - 30 degreeC for 2 hours, it stirred at 125 degreeC for 2 hours.

[0224] DDS 0.95g

[0225] PGMEA 7.04g

[0226] [Z / Y=2.7, (Y+Z) / X=0.9]

[0227] Thereafter, the reaction liquid was cooled to 25° C., trimellitic anhydride (TMA) and PGMEA were added by the following weights, and stirred at 20° C. to 30° C. for 2 hours.

[0228] TMA0.24g

[0229] PGMEA 6.15g

[0230] The solution was cooled to room temperature to obtain a 30% by weight solution of a pale yellow transparent polyester amic ...

Embodiment 1

[0236] A 30% by weight solution of polyester amic acid (A1), M-520, NCI-930, VG3101L, TMA, ND-139, 2 -Hydroxy-1,4-naphthoquinone, S510, AO-60, BYK-342, PGMEA, PGME, and EDM were mixed and dissolved, and filtered with a membrane filter (0.2 μm) to obtain a photosensitive composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com