Rare earth permanent magnet and preparation method thereof

A rare earth permanent magnet and magnet technology, which is applied in the fields of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem that the diffusion amount of heavy rare earth elements is difficult to control, and achieve the effect of simple process and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of a rare earth permanent magnet. This preparation method comprises the following steps:

[0030] S1, provide a first magnetic powder and a second magnetic powder respectively, wherein the first magnetic powder is alloy magnetic powder B, the second magnetic powder is alloy magnetic powder R or mixed magnetic powder A, and the mixed magnetic powder A is obtained by mixing alloy magnetic powder B and alloy powder, so The coercive force of the magnet prepared by the second magnetic powder is higher than that of the magnet prepared by the first magnetic powder;

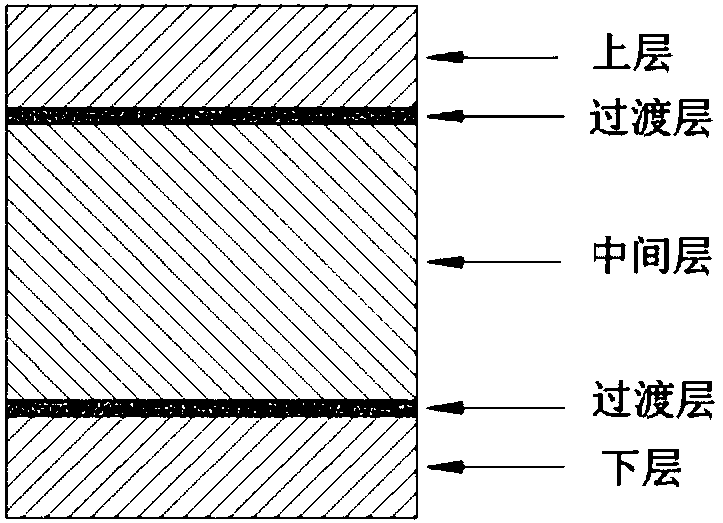

[0031] S2, placing the first magnetic powder in the middle part of a mould, placing the second magnetic powder in the upper part and the lower part of the mould, and performing thermocompression molding to obtain a thermocompressed magnet;

[0032] S3, performing thermal deformation molding on the hot-pressed magnet to obtain a rare earth permanent magnet, the rare eart...

Embodiment 1

[0053] According to neodymium copper alloy (Nd 70 Cu 30 , at%) in the proportion of neodymium and copper elements in precise batching, and made ingots in a vacuum induction melting furnace, using a rapid quenching furnace to make it into a rapid quenching thin strip, and then mechanically crushed to make a particle size of about 200μm neodymium copper alloy powder.

[0054] The neodymium-copper alloy powder and the composition are Nd 29.8 PR 0.4 Ga 0.5 Fe bal. co 4 B 0.93 The NdFeB master alloy magnetic powder is evenly mixed to obtain the mixed magnetic powder, wherein the neodymium-copper alloy powder accounts for 4% of the total mass of the mixed magnetic powder.

[0055] Put the mixed magnetic powder and NdFeB master alloy magnetic powder into the first mold for hot pressing, wherein the mixed magnetic powder is placed in the upper and lower parts of the first mold, and the NdFeB master alloy magnetic powder is placed in the middle part of the first mold. The mass ...

Embodiment 2

[0059] This preparation method is basically the same as that of Example 1, except that the mass ratio of the mixed magnetic powder to the NdFeB master alloy magnetic powder is 1:3 during hot pressing, the highest temperature of hot pressing is 670°C, and the highest temperature of hot deformation It is 830°C.

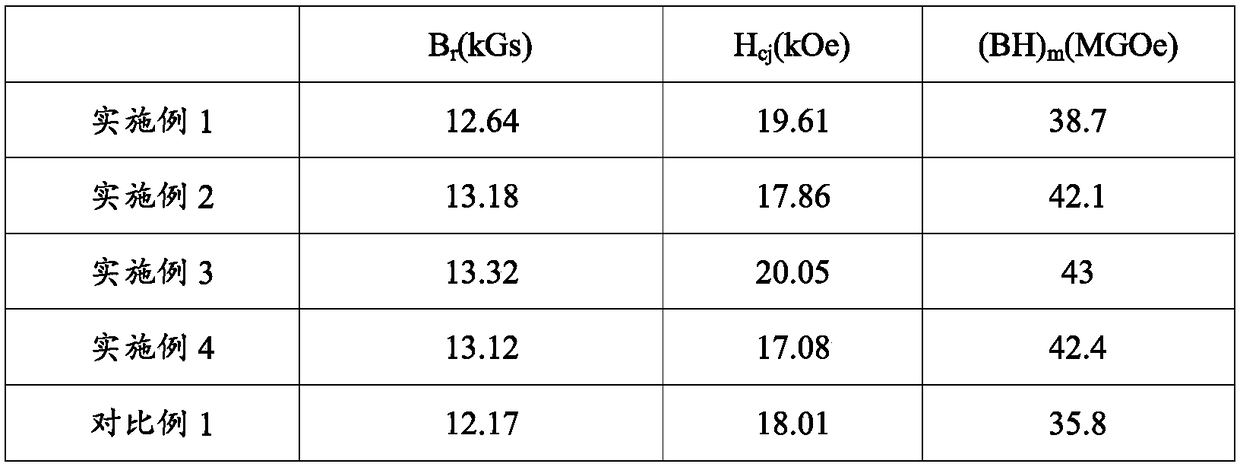

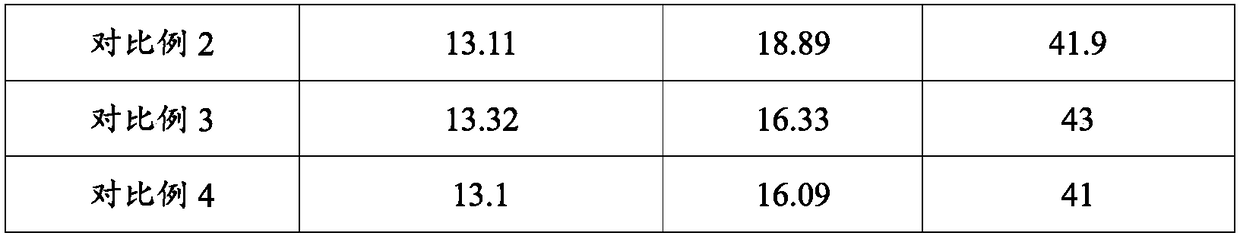

[0060] The magnetic properties of the obtained rare earth permanent magnet were tested at room temperature, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com