Semiconductor structure and formation method thereof

A technology of semiconductors and transistors, applied in the field of semiconductor structures and their formation, can solve the problems that the electrical properties of semiconductor structures need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

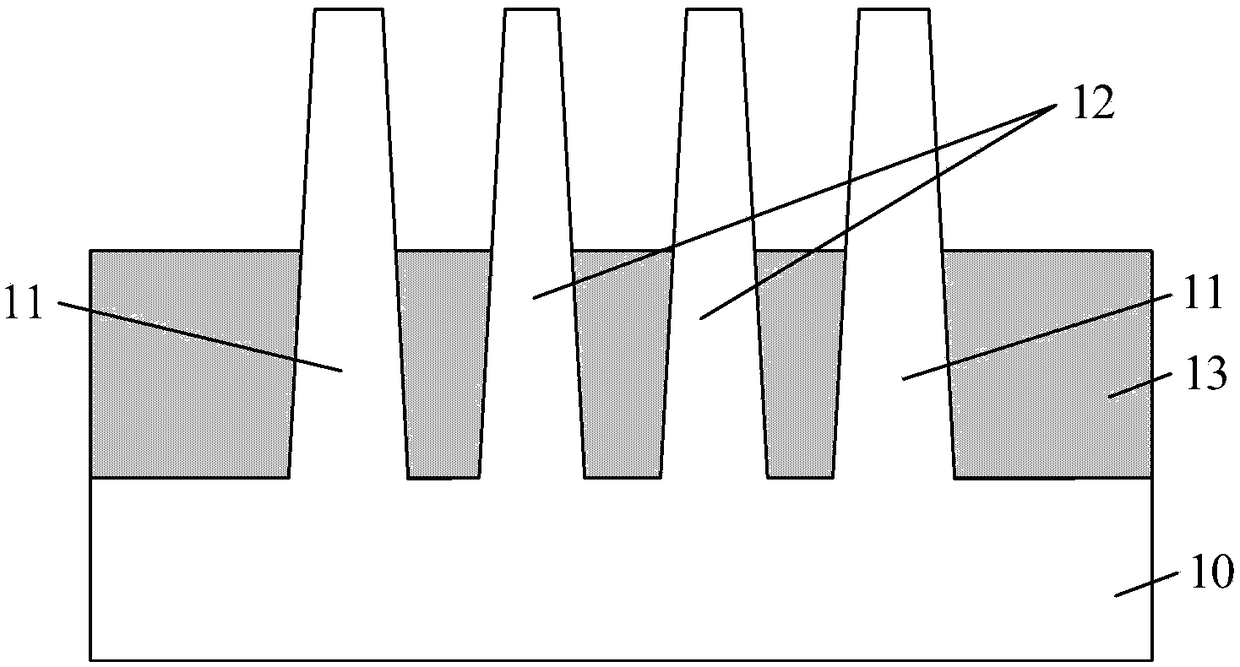

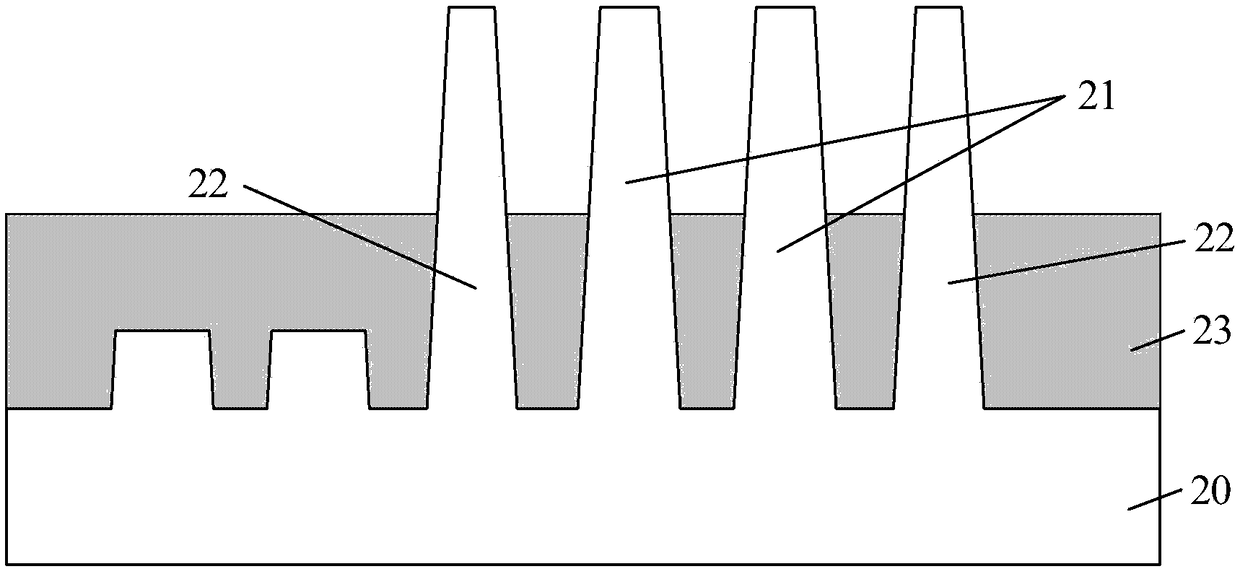

[0016] In order to improve the short channel effect, a common method is to perform an anti-punch through implant (Anti-punch Through Implant) process on the fin to form an anti-punch doping ion region in the fin. However, the electrical performance of the formed semiconductor structure still needs to be improved after introducing anti-punching ion implantation. Analyze the reasons for this:

[0017] In semiconductor manufacturing, with the continuous reduction of feature size, in order to effectively fill the lithography gap of smaller nodes and improve the minimum pitch between adjacent semiconductor patterns, self-alignment process is more and more widely used. It is applied in fin formation process, such as self-aligned double patterned (Self-aligned Double Patterned, SADP) process. According to actual process requirements, the substrate includes a first region and a second region, the first region is used to form fin field effect transistors, and the second region is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com