Lithium di-ionic total battery using mixed carbon material as positive and negative electrodes

A hybrid carbon, positive and negative technology, used in battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as commercialization of high-cost dual-ion batteries, and achieve structural stability, environmental friendliness, and positive and negative electrodes. Material stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

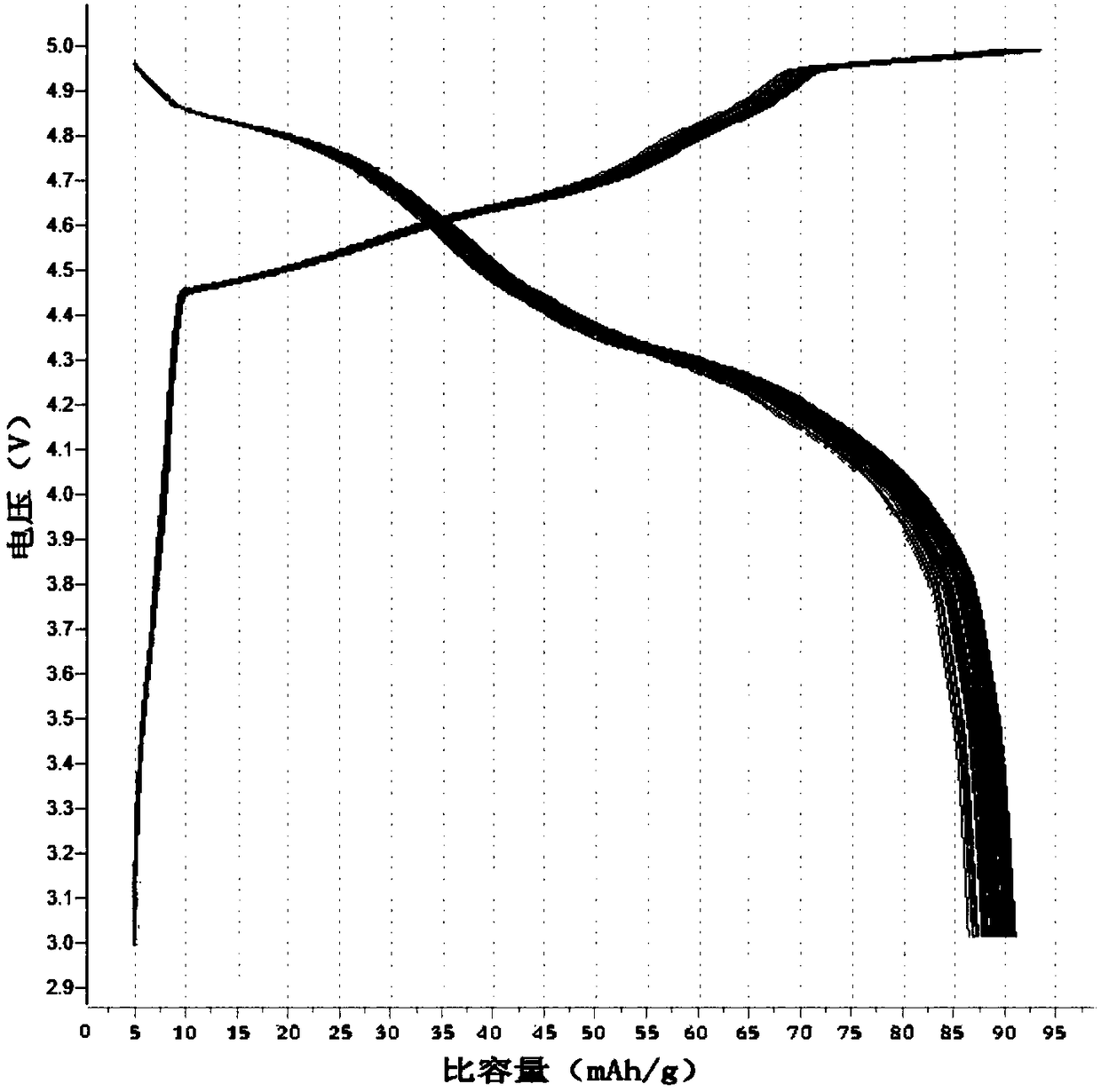

Examples

Embodiment 1

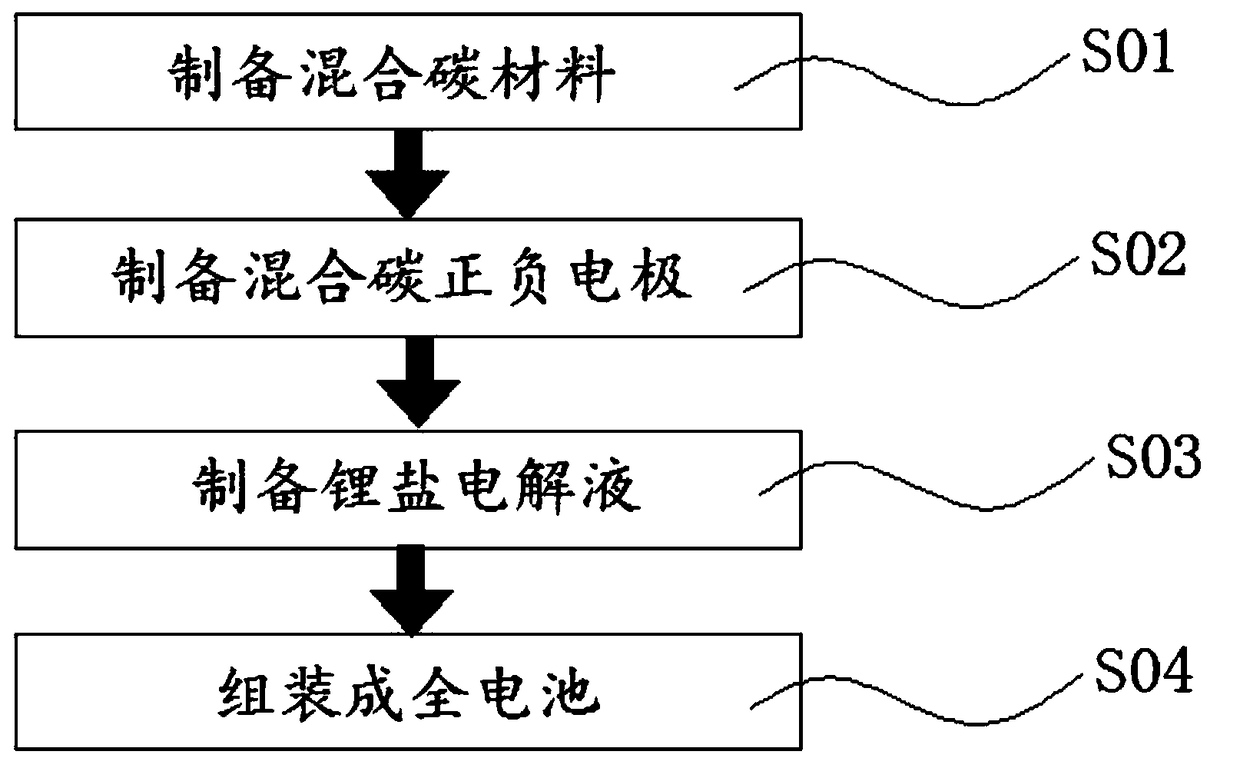

[0041] S01, prepare mixed carbon material:

[0042]Mix graphene and nano-graphene at a weight ratio of 6:4, then grind for 12 hours in a water-resistant environment, then raise the temperature to 100°C at a rate of 3°C under a protective gas atmosphere, and then treat at a constant temperature for 15 hours to obtain a mixed carbon materials;

[0043] S02, preparing mixed carbon positive and negative electrodes;

[0044] Mix the mixed carbon material obtained by S01: acetylene black: carboxymethyl cellulose in a mass ratio of 8:1:1; then dissolve the mixture in ethanol: H 2 The mass ratio of O was 1:2 in the mixed solution and continued to stir for 20h; then the mixture was mixed according to the average weight of the carbon material about 4mg / cm 2 Coated on the aluminum foil of the positive electrode substrate, the average weight of the mixed carbon material is about 2mg / cm 2 Coated on the negative electrode substrate copper foil, and dried them in a vacuum oven at 70°C for...

Embodiment 2

[0052] S01, prepare mixed carbon material:

[0053] Graphene and molybdenum disulfide were mixed at a weight ratio of 8:2, then ground for 12 hours in a water-resistant environment, and then heated to 100°C at a rate of 3°C under a protective gas atmosphere, and then treated at a constant temperature for 15 hours to obtain a mixed carbon material 1;

[0054] Mix nano-graphite and NiCoO4 at a mass ratio of 9:1, then grind for 15 hours in a water-absolute environment, then raise the temperature to 100°C at a rate of 3°C under a protective gas atmosphere, and then treat at a constant temperature for 18 hours to obtain a mixed carbon material 2;

[0055] S02, preparing mixed carbon positive and negative electrodes;

[0056] Mix the mixed carbon material 1 obtained in S01: acetylene black: carboxymethyl cellulose in a mass ratio of 8:1:1; then dissolve the mixture in ethanol: H 2 The mass ratio of O was 1:2 in the mixed solution and continued to stir for 20h; then the mixture wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com