Modular energy storage and powder generation device

A power generation device, modular technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of limited power, strong volatility, waste, etc., and achieve the effect of small starting torque, high energy conversion efficiency, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

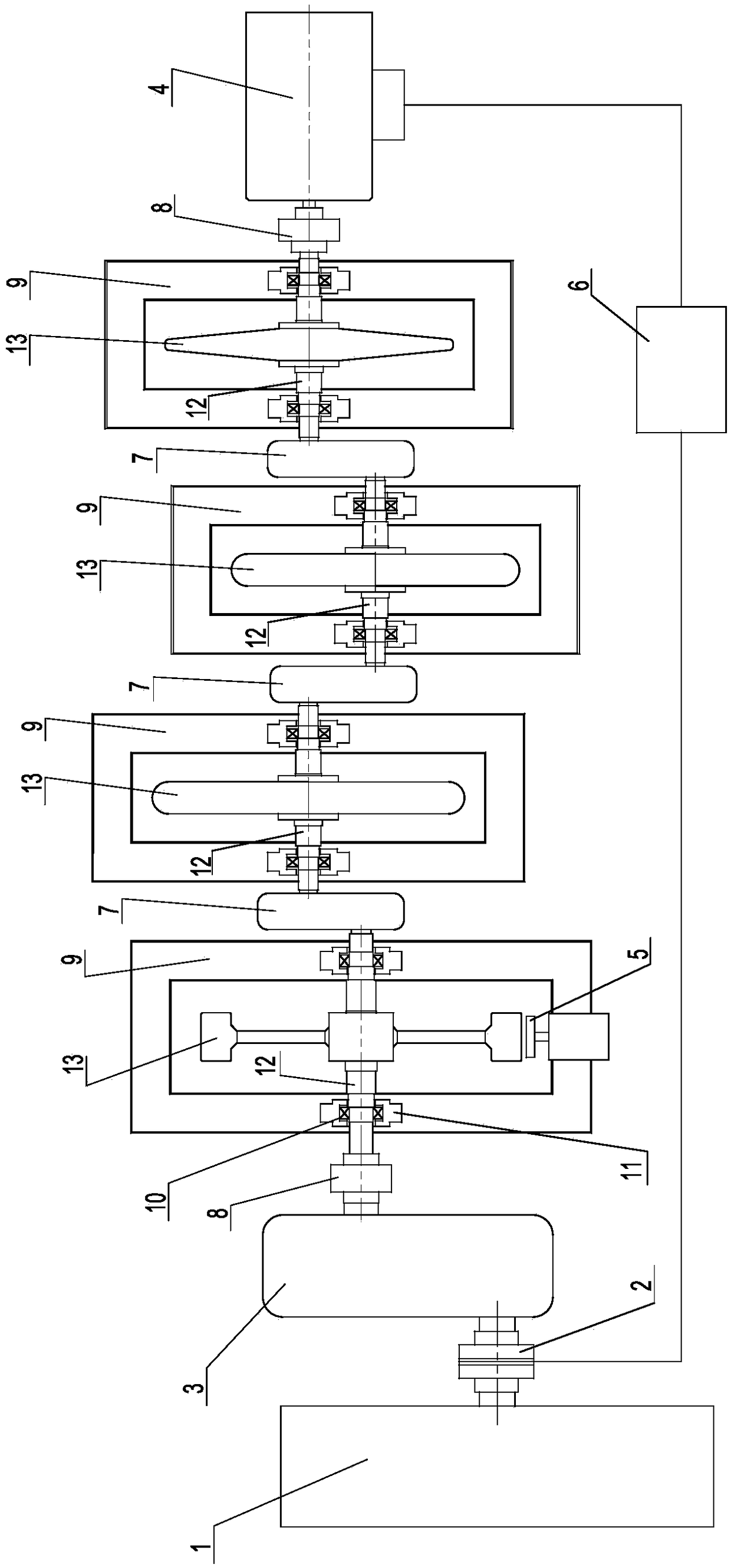

[0015] The present invention will be further described below in conjunction with the accompanying drawings. exist figure 1 The shown embodiment is a 50 kW generator: including drive source 1, first coupling 2 with clutch function, two second couplings 8 reducer 3, generator 4, reducer 5, with display Functional controller 6, 3 gearboxes 7, 2 second couplings 8 and 4 flywheel modules, wherein the power output end of the drive source 1 is connected to the input end of the reducer 3 through the first coupling 2, and the second A control terminal of the coupling 2 and the generator 4 is connected to the signal output terminal of the controller 6 . A gearbox 7 is arranged between adjacent flywheel modules, which are respectively connected to the output and input ends of adjacent flywheel modules; each flywheel module includes a support frame 9, which is horizontally installed on the support through the cooperation of bearing 10 and bearing seat 11. The transmission shaft 12 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com