Preparation method of cashew apple juice

A technology of cashew pear and fruit juice, which is applied in the field of preparation of cashew pear juice, can solve the problem that the utilization rate of cashew pear is less than 30%, and achieve the effects of shortening the preparation time, improving the preparation efficiency, and shortening the enzymatic hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

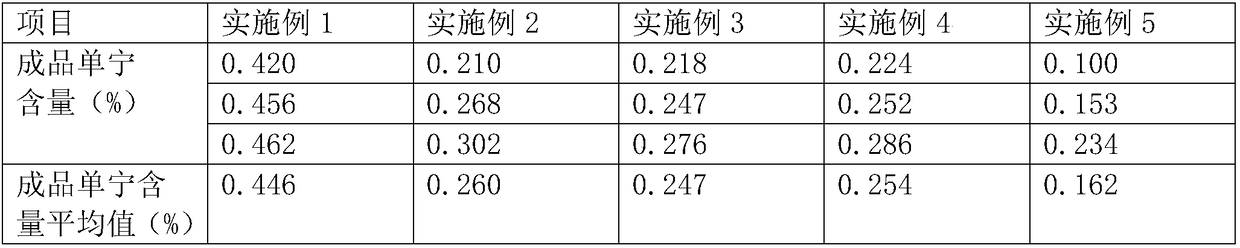

Examples

Embodiment 1

[0029] A preparation method of cashew pear juice, specifically comprising the following steps:

[0030] (1) Select the fresh fruit of cashew nut pear with more than eight mature yellow or red sizes, remove insect damage, disease and moldy and rotten fruit, and then wash the fresh fruit with a fruit cleaning machine.

[0031] (2) Using a screw press to squeeze the fresh fruit to obtain the original juice, the squeezed juice rate is 50%. The cashew pear contains a large amount of dietary fiber and does not need to be broken.

[0032] (3) The percentages of the amount of enzyme added in the enzymolysis to the total raw material content are: 0.01% pectinase, 0.03% cellulase, and 0.02% tannase. The enzymolysis temperature is 50° C. for 1 hour. The heat treatment includes heating the raw juice after enzymolysis at 80° C. for 5 minutes.

[0033] (4) The cooled original juice in (3) is filtered by a filter to remove suspended solids and colloidal substances to obtain clear juice.

...

Embodiment 2

[0036] A preparation method of cashew pear juice, specifically comprising the following steps:

[0037] (1) Select the fresh fruit of small yellow cashew pear with more than eight ripeness, and remove insect damage, disease and mildew; select fresh pineapple fruit with more than eight maturity, remove insect damage, disease and mildew, and then wash the fresh fruit with a fruit washing machine.

[0038] (2) Using a screw press to squeeze the fresh fruit to obtain the original juice, the squeezed juice yield is 50%. Cashew pears and pineapples contain a large amount of dietary fiber and do not need to be broken.

[0039] (3) The percentages of the total content of the original juice are: 0.01% pectinase, 0.01% cellulase, and 0.005% tannase enzymes are added to the original juice and enzymatically hydrolyzed at a temperature of 40°C 2h. The raw juice after enzymolysis was heated at 80°C for 5 minutes and then cooled.

[0040] (4) The cooled original juice in (3) is filtered by...

Embodiment 3

[0043] A preparation method of cashew pear juice, specifically comprising the following steps:

[0044] (1) Select the fresh fruit of large red cashew pear with more than eight ripeness, and remove insect damage, disease and mildew; select fresh pineapple fruit with more than eight maturity, remove insect damage, disease and mildew, and then wash the fresh fruit with a fruit washing machine.

[0045] (2) Fresh fruit is squeezed by a screw press to obtain raw juice, and the squeezed juice yield is 60%. Cashew pears and pineapples contain a large amount of dietary fiber and do not need to be broken.

[0046] (3) The percentages of the total content of the raw juice are: 0.02% pectinase, 0.03% cellulase, and 0.02% tannase enzymes are added to the raw juice and enzymatically hydrolyzed at a temperature of 55°C 0.5h. The enzymatically hydrolyzed cashew pear juice and pineapple juice were respectively heated at 90° C. for 3 min and then cooled.

[0047] (4) The cooled original jui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com