Natural essential oil hair conditioner and preparation method thereof

A technology for natural essential oils and conditioners, applied in skin care preparations, hair care, pharmaceutical formulations, etc., can solve problems such as static electricity generation and inconvenience in combing, and achieve the effects of various types, good compatibility and high overall oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

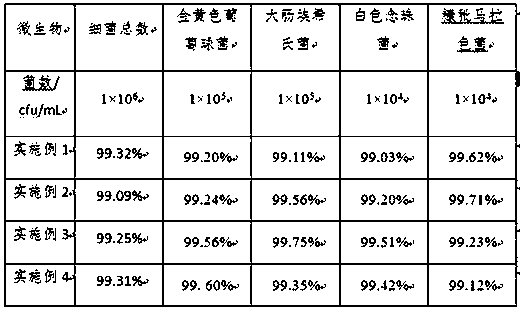

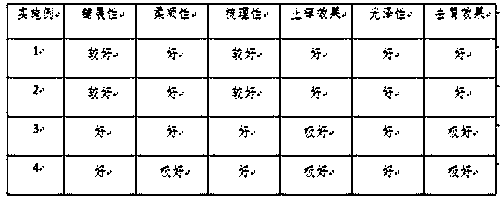

Examples

Embodiment 1

[0028] (1) Mix 40g of deionized water, 5g of behenyltrimethylammonium chloride, 5g of stearyltrimethylammonium chloride, and 0.1g of EDTA, heat up to 75°C, and keep stirring at this temperature for 1 hour;

[0029] (2) Mix 5g propylene glycol, 0.4g tea tree oil, 0.3g clove oil, 0.2g geranium oil, 0.2g rosemary leaf oil, 0.2g rose essential oil, 0.3g sweet orange essential oil, 0.2g pomelo peel oil, 0.3g lemon Oil, 0.3g jojoba seed oil, 0.2g sesame seed oil, 0.2g thyme oil, 0.4g lavender oil, 1g ceteareth-20 mixed, heated up to 65°C, kept stirring at this temperature for 1h;

[0030] (3) Put the product obtained in steps (1) and (2) in a homogeneous emulsifier, set the stirring speed to 800r / min, adjust the temperature to 70°C, and stir for 30 minutes to make the mixture fully Dissolve, and achieve emulsification and homogeneity;

[0031] (4) Cool down to 50°C, add 0.1g vitamin E, 2g hydrolyzed vegetable protein, and stir for 20 minutes;

Embodiment 2

[0035] (1) Mix 50g of deionized water, 7g of behenyltrimethylammonium methosulfate, 8g of polyquaternium-67, and 0.2g of EDTA, heat up to 80°C, and keep stirring at this temperature for 1 hour;

[0036] (2) 6g glycerin, 0.4g tea tree oil, 0.1g clove oil, 0.2g geranium oil, 0.3g rosemary leaf oil, 0.2g peppermint oil, 0.2g sweet orange essential oil, 0.3g pomelo peel oil, 0.3 g fennel oil, 0.3g lemon oil, 0.3g jojoba seed oil, 0.2g thyme oil, 0.4g lavender oil, 0.1g sage oil, mix with 3g ceteareth-25, heat up to 70 ℃, keep stirring at this temperature for 1h;

[0037] (3) Put the product obtained in steps (1) and (2) in a homogeneous emulsifier, set the stirring speed to 1000r / min, adjust the temperature to 75°C, and stir for 25 minutes to make the mixture fully Dissolve, and achieve emulsification and homogeneity;

[0038] (4) Cool down to 40°C, add 0.2g vitamin E, 3g hydrolyzed vegetable protein, and stir for 40 minutes;

[0039] (5) Add 2g of sodium chloride and 0.2g of c...

Embodiment 3

[0042] (1) Mix 60g of deionized water, 5g of behenyltrimethylammonium chloride, 8g of polyquaternium-67, and 0.3g of EDTA, heat up to 85°C, and keep stirring at this temperature for 1 hour;

[0043] (2) Mix 7g ethylhexylglycerol, 0.4g tea tree oil, 0.3g basil essential oil, 0.2g geranium oil, 0.2g rosemary leaf oil, 0.2g rose essential oil, 0.3g sweet orange essential oil, 0.2g pomelo peel oil, 0.3g lemon oil, 0.3g jojoba seed oil, 0.2g grape seed oil, 0.2g thyme oil, 0.4g lavender oil, 0.2g sage oil, 2g ceteareth-20 mixed, heated The temperature was raised to 80°C, and the temperature was kept stirring for 1h;

[0044] (3) Put the product obtained in steps (1) and (2) in a homogeneous emulsifier, set the stirring speed at 1500r / min, raise the temperature to 70°C, and stir for 20 minutes to fully dissolve the mixture under strong shear force , and achieve emulsification and homogeneity;

[0045] (4) Cool down to 45°C, add 0.3g vitamin E, 2g hydrolyzed vegetable protein, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com