Organic waste treatment system

A processing system and organic waste technology, applied in grain processing, presses, magnetic separation, etc., can solve the problems of affecting processing efficiency, unreasonable structure setting of crushing knives, and low efficiency of waste crushing, so as to improve fermentation efficiency and reduce labor Strength, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

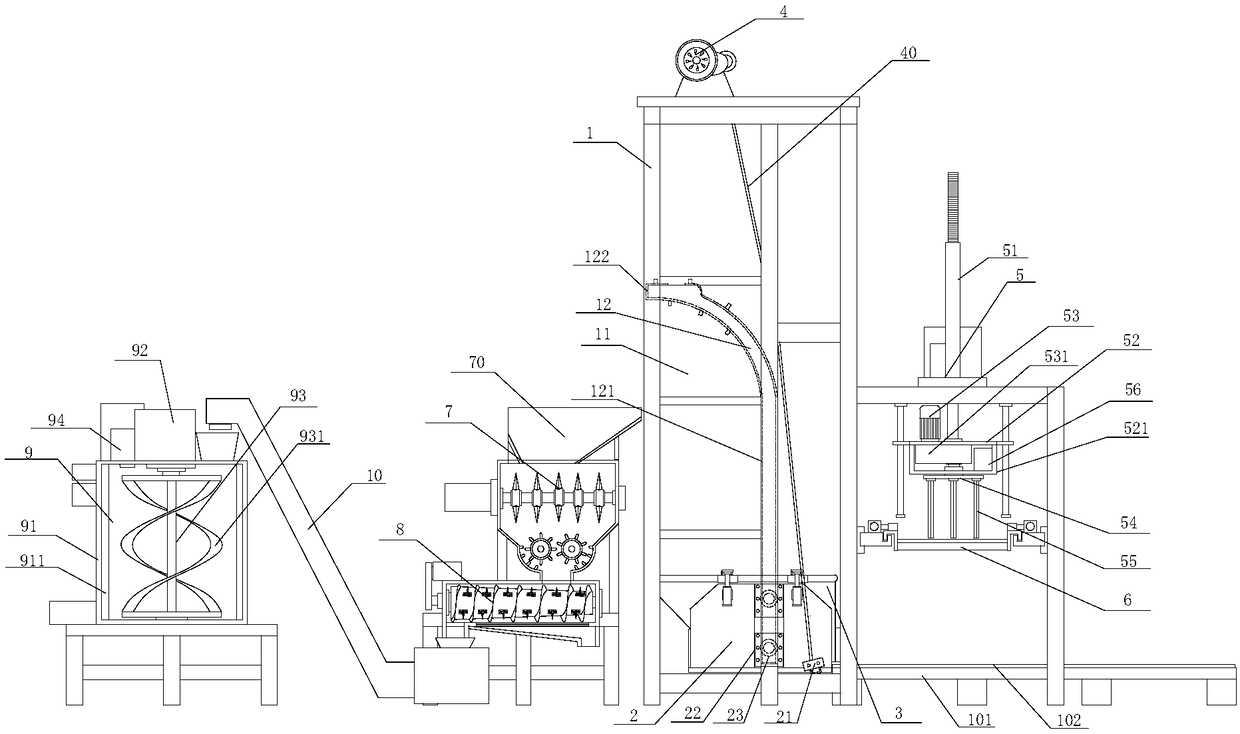

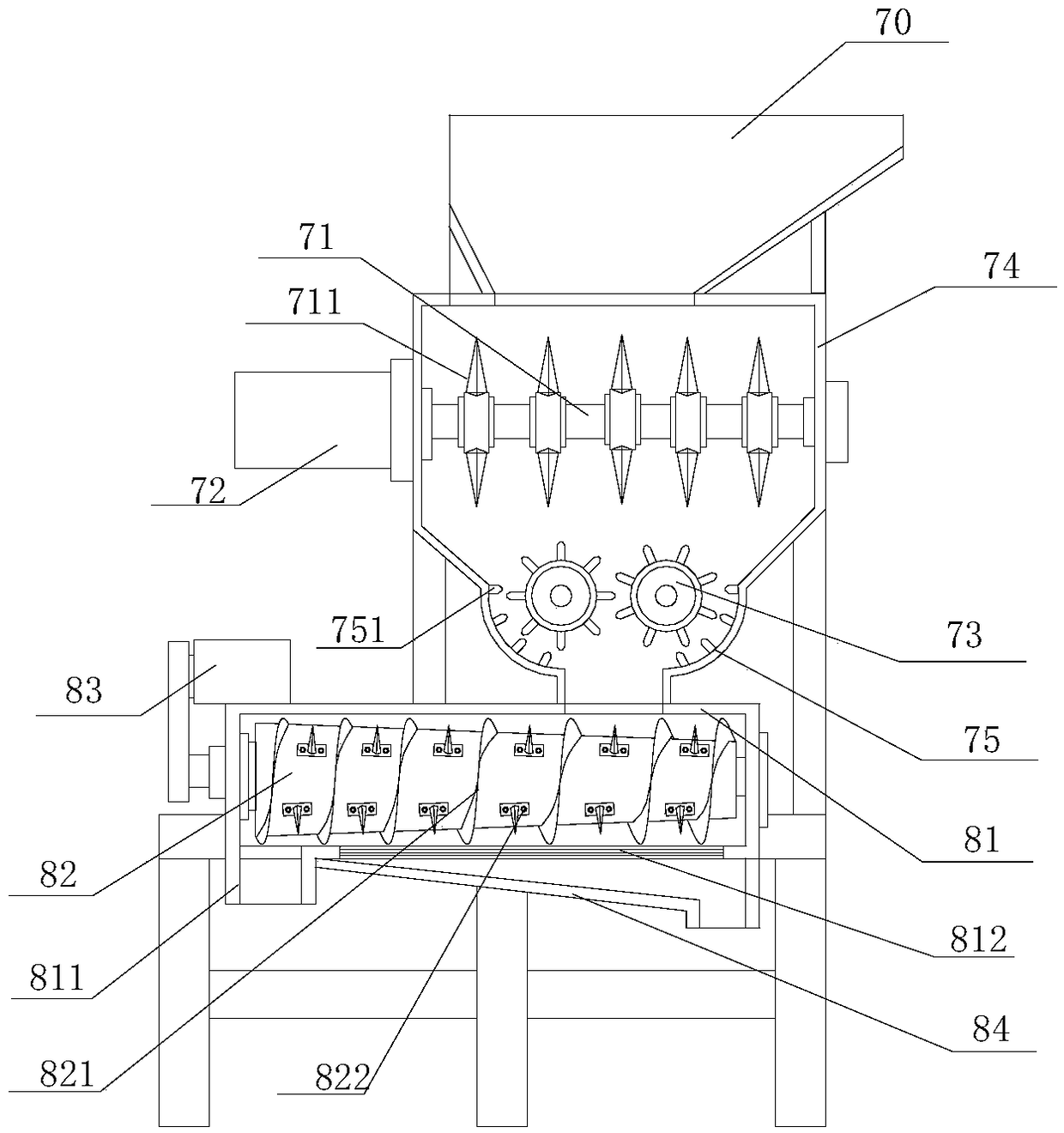

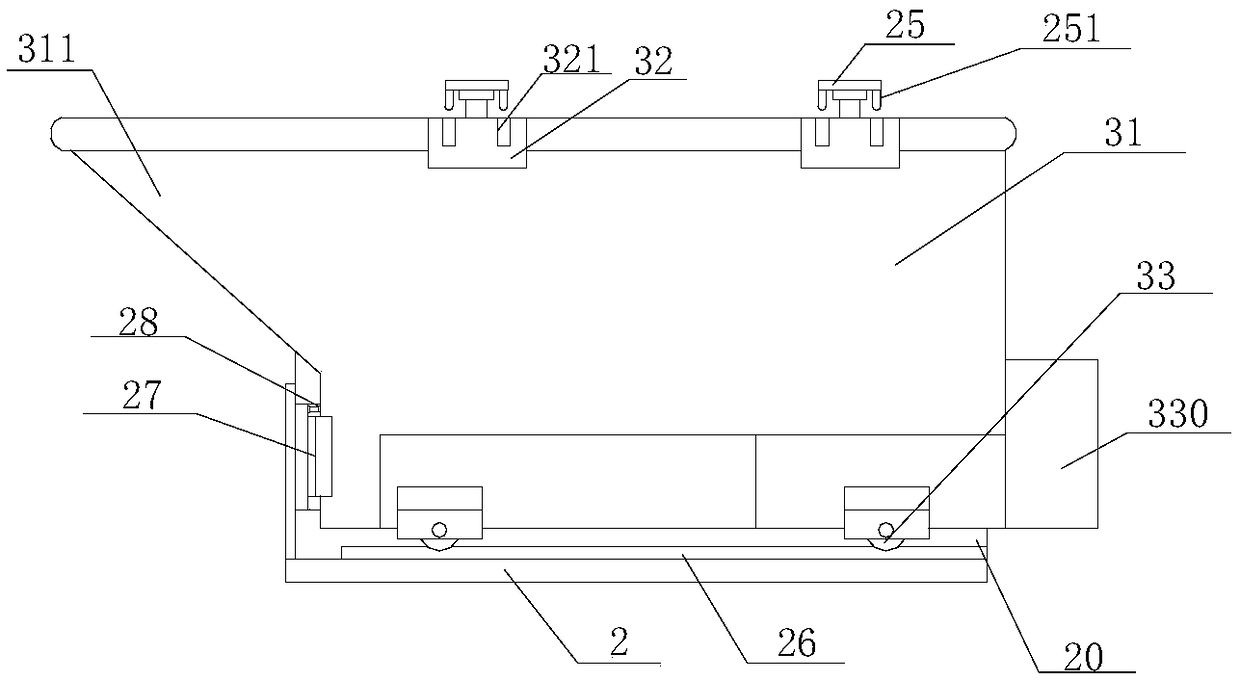

[0022] refer to Figure 1 to Figure 5, an organic waste treatment system of the present invention, comprising a frame 1, a lifting mechanism 2, a feeding trolley 3, a winding roller lifting mechanism 4, a magnetic impurity removal device 5, an impurity removal and discharging mechanism 6, a crushing mechanism 7, and a dehydration mechanism 8. The biological fermentation mechanism 9 and the screw conveying mechanism 10, the winding roller lifting mechanism 4 is installed above the frame 1, and the winding roller lifting mechanism 4 drives the lifting mechanism 2 along the feeding turning track 12 through the traction rope 40 Moving, the feeding trolley 3 cooperates with the lifting mechanism 2, the right side of the frame 1 is provided with a magnetic impurity removal device 5, and the left side of the frame 1 is provided with a crushing mechanism 7, and the crushing mechanism 7 A first crushing assembly 71 is provided inside, and two crushing rollers 73 are arranged below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com