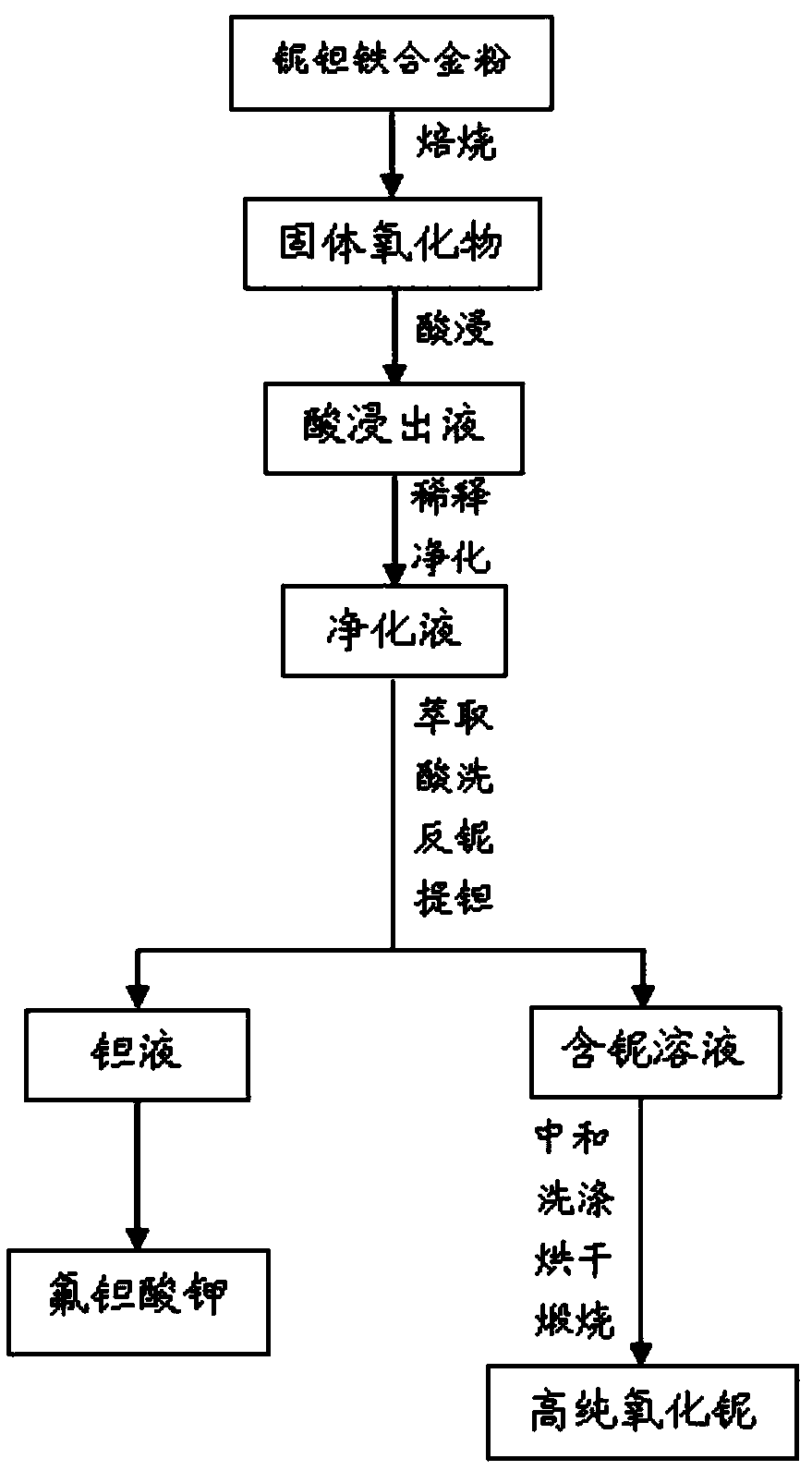

Method for preparing high-purity niobium oxide through niobium-tantalum-iron alloy

A technology of ferroalloy and niobium oxide, which is applied in the field of niobium oxide preparation, can solve problems such as explosion, failure to meet actual needs, and influence on the purity and quality of niobium oxide, and achieve efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the present invention, the preparation method of the purification agent preferably includes: melting the raw materials according to the chemical composition of the purification agent to obtain an alloy melt; water quenching, crushing and sieving the alloy melt in sequence to obtain purifier. The present invention has no special requirements on the specific sources of the raw materials, and commercially available products well known to those skilled in the art can be used. In the present invention, there is no special requirement on the smelting method of the raw materials, and a method well known to those skilled in the art can be used. The present invention has no special requirements on the specific implementation methods of the water quenching, crushing and sieving, and methods well known to those skilled in the art can be used.

[0048] In the present invention, the volume ratio of the mass of the purifying agent to the diluent is preferably 110 to 125 kg / m 3 ,...

Embodiment 1

[0067] The niobium-tantalum-iron alloy powder with the composition shown in Table 1 was used.

[0068] Table 1 Chemical composition of niobium-tantalum-iron alloy

[0069] element

Ta

Nb

W

Si

Al

Cu

Fe

Sb

S

P

C

Mass content

3.51

39.62

0.06

18.3

1.7

1.5

28.4

0.12

2.17

2.2

1.09

[0070] The niobium-tantalum-iron alloy was crushed and ground to 300 mesh, and roasted at 850°C for 3 hours to obtain a solid oxide; the main impurities in the solid oxide were detected and analyzed: copper: 1.35%, antimony: 0.1%, sulfur: 0.52%, phosphorus: 0.31%, Carbon: 0.06%;

[0071] Carry out acid leaching with hydrofluoric acid and sulfuric acid by the ratio of mass ratio 1:1.4:0.9 of solid oxide, react for 16 hours, wherein, hydrofluoric acid mass concentration is 55%, sulfuric acid mass concentration is 98%, obtains acid leaching solution, Its chemical composition is as follows: Nb 2 o 5 :185.6g / L,Ta ...

Embodiment 2

[0077] The tantalum-niobium-iron alloy is processed according to the method of Example 1, the difference is that the chemical composition of the purifying agent (shown in Table 2), the particle size of the tantalum-niobium-iron alloy powder is 280 mesh, and the oxidation roasting temperature is 870 ° C. 6.5% NaNO 2 , the extractant used is MIBK, calcined at 850°C for 5h, other details are shown in Table 2-3. The results obtained in this example are tested, and the purity of high-purity niobium oxide meets the non-ferrous metal industry standard FNb 2 o 5 -04 grade requirements.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap