Low temperature firing light ceramic product and production technology thereof

A light-weight ceramic and low-temperature firing technology, which is applied in the field of ceramics, can solve problems such as high water absorption, inconvenient use, and non-wearable surface, and achieve the effects of reducing specific gravity, reducing water absorption, and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

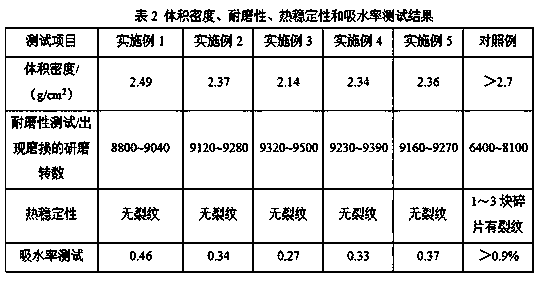

[0024] This embodiment provides a low-temperature fired light-weight ceramic product and its manufacturing process, including the following raw materials in parts by weight: 20 parts of expanded vermiculite, 10 parts of sea foam mud, 17 parts of fumed white carbon black, 20 parts of potassium feldspar, 45 parts of black talc, 5 parts of nano-barium carbonate, 10 parts of glass powder, 3 parts of nano-alumina, 15 parts of water glass, 15 parts of calcined zeolite, 5 parts of obsidian and 12 parts of nano-boron nitride.

[0025] This embodiment also provides a process for manufacturing low-temperature firing light ceramic products, comprising the following steps:

[0026] Step 1, take each raw material respectively according to weight part, set aside;

[0027] Step 2, crushing and grinding the calcined zeolite to pass through a 300-mesh sieve to obtain raw material powder A;

[0028] Step 3, after mixing other raw materials except calcined zeolite, crush and grind to pass throu...

Embodiment 2

[0032]This embodiment provides a kind of low-temperature fired light-weight ceramic product and its manufacturing process, including the following raw materials in parts by weight: 25 parts of expanded vermiculite, 15 parts of sea foam mud, 19 parts of fumed white carbon black, 25 parts of potassium feldspar, 50 parts of black talc, 7 parts of nano-barium carbonate, 11 parts of glass powder, 5 parts of nano-alumina, 17 parts of water glass, 16 parts of calcined zeolite, 10 parts of obsidian and 14 parts of nano-boron nitride.

[0033] This embodiment also provides a process for manufacturing low-temperature firing light ceramic products, comprising the following steps:

[0034] Step 1, take each raw material respectively according to weight part, set aside;

[0035] Step 2, crushing and grinding the calcined zeolite to pass through a 375-mesh sieve to obtain raw material powder A;

[0036] Step 3, after mixing other raw materials except calcined zeolite, crush and grind to pa...

Embodiment 3

[0040] This embodiment provides a kind of low-temperature fired light-weight ceramic product and its manufacturing process, including the following raw materials in parts by weight: 30 parts of expanded vermiculite, 20 parts of sea foam mud, 22 parts of fumed white carbon black, 30 parts of potassium feldspar, 56 parts of black talc, 10 parts of nano-barium carbonate, 13 parts of glass powder, 6 parts of nano-alumina, 19 parts of water glass, 18 parts of calcined zeolite, 15 parts of obsidian and 17 parts of nano-boron nitride.

[0041] This embodiment also provides a process for manufacturing low-temperature firing light ceramic products, comprising the following steps:

[0042] Step 1, take each raw material respectively according to weight part, set aside;

[0043] Step 2, crushing and grinding the calcined zeolite to pass through a 450-mesh sieve to obtain raw material powder A;

[0044] Step 3, after mixing other raw materials except calcined zeolite, crush and grind to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com