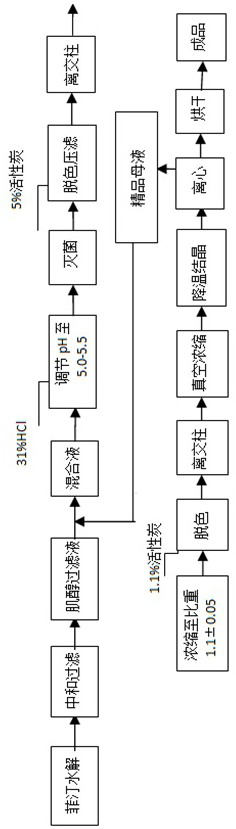

Refining process of inositol filtrate high temperature and rapid separation

A high-temperature, fast, inositol technology, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of high inositol conductivity, low inositol yield, long process cycle, etc., and increase the yield of inositol , Improve the purity of inositol and improve the effect of desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037]The preparation method of the mixed solution in the following examples is:

[0038]According to the solid / liquid ratio of 1:4, add phytin to clear water, stir in a pressurized and stirred hydrolysis kettle and heat to 180℃, pressure 0.8MPa, hydrolyze at this temperature and pressure for 6 hours to obtain inositol hydrolysis liquid. Hydrolyze the inositol hydraulically into the neutralization kettle, that is, use 15% calcium hydroxide solution to neutralize to a pH of 8-10. The neutralization liquid is filtered to obtain the inositol filtrate. Mix the inositol filtrate and the refined mother liquor at a ratio of 1.6:1, and the test indicators of the mixture are as follows.

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com