Method for refining pumpkin oligosaccharides by using macroporous resin

A technology of macroporous resin and refining method, which is applied in the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc., can solve the problems of low removal rate of impurities, poor decolorization effect of colored substances, and destruction of oligosaccharide structure, etc. Achieve high purity, less waste, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

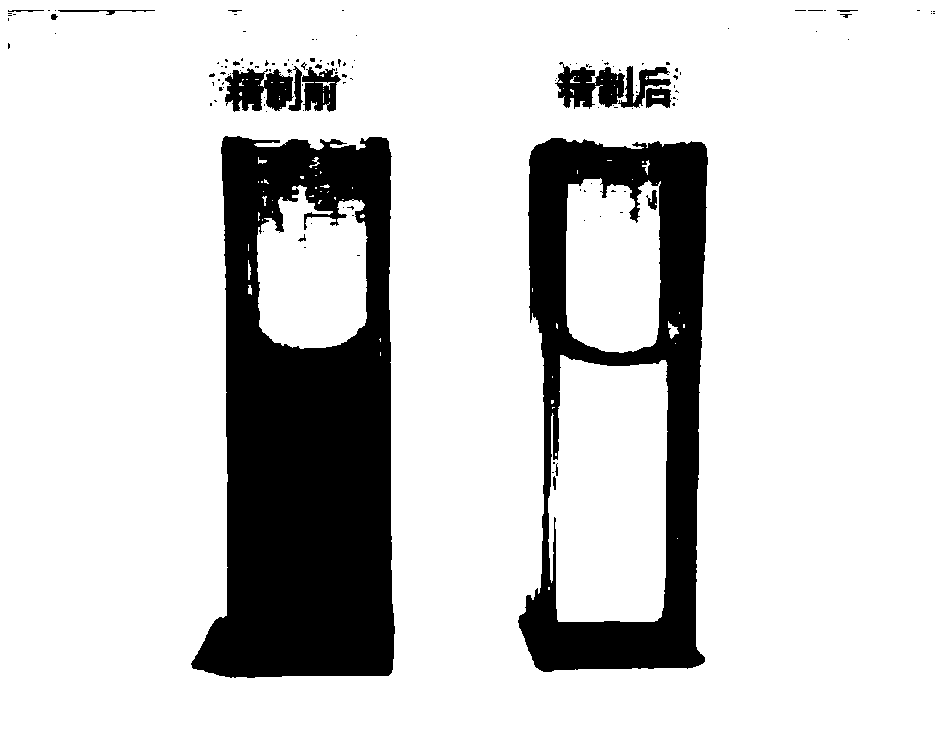

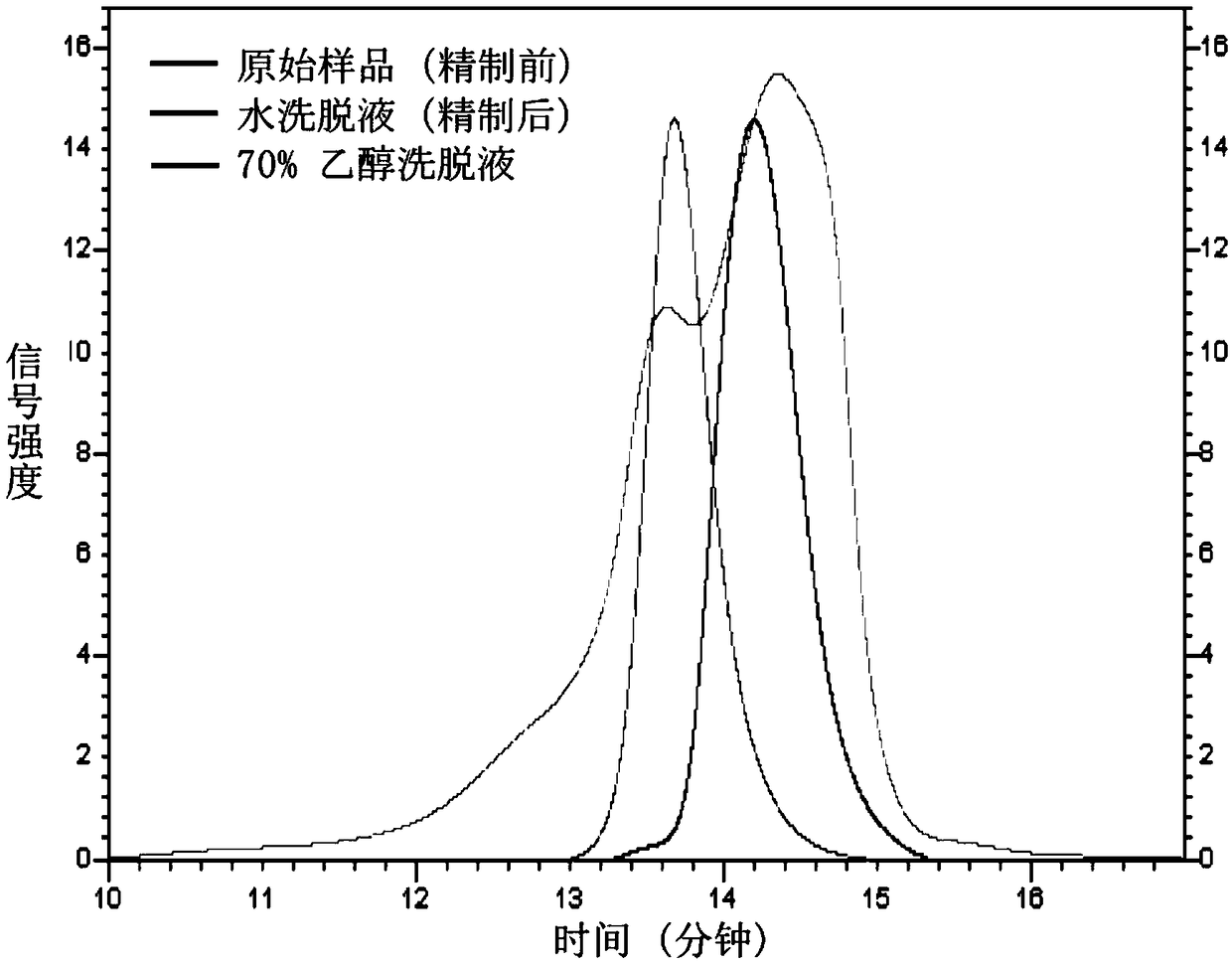

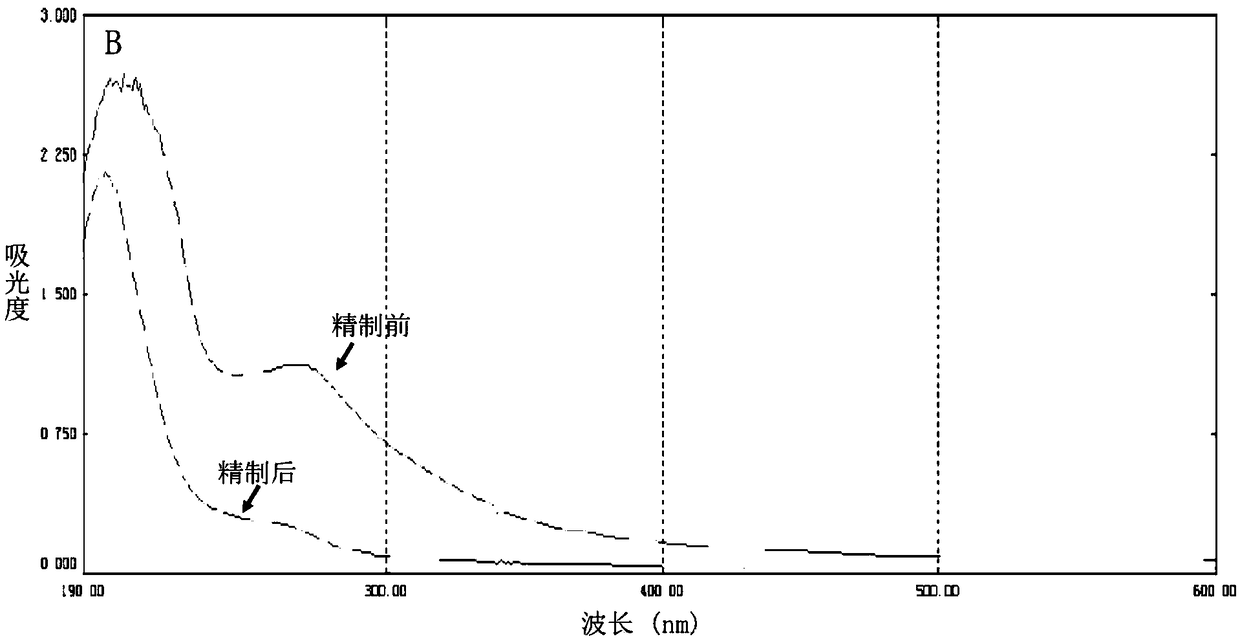

Image

Examples

Embodiment 1

[0049] A method for refining pumpkin oligosaccharides by using macroporous resin, carried out according to the following steps:

[0050] (1) Macroporous resin pretreatment: Soak DM28 macroporous adsorption resin in deionized water for 24 hours, wash with ethanol until it is not cloudy, soak in ethanol for 24 hours, wash with water until there is no alcohol smell, and use a NaOH solution with a mass percentage concentration of 5%. Pass through the resin column and soak for 2h, wash with water until neutral, pass HCl with a mass percentage concentration of 5% through the resin column and soak for 4h, wash with water until neutral, and set aside at 4°C; when in use, pack into a chromatography column (6cm×80cm) 3 / 4 places, to ensure that the filling is even and flat without air bubbles;

[0051] (2) Add water to the pumpkin oligosaccharide crude extract to form a solution with a concentration of 250 mg / ml, and pass the above-mentioned solution of 1.0 times column volume (BV) thro...

Embodiment 2

[0063] A method for refining pumpkin oligosaccharides by using macroporous resin, carried out according to the following steps:

[0064] (1) Macroporous resin pretreatment: Soak DM21 macroporous adsorption resin in deionized water for 30 hours, wash with ethanol until it is not cloudy, soak in ethanol for 30 hours, wash with water until there is no alcohol smell, and use a NaOH solution with a mass percentage concentration of 5%. Pass through the resin column and soak for 4 hours, wash with water until neutral, pass HCl with a mass percentage concentration of 5% through the resin column and soak for 4 hours, wash with water until neutral, and set aside at 4°C; when used, it is loaded into 3 / 4 of the chromatography column to ensure The filling is even and smooth without air bubbles;

[0065] (2) add water to pumpkin oligosaccharide crude extract to form a solution with a concentration of 280 mg / ml, and pass the above-mentioned solution of 1.5 times column volume (BV) through a ...

Embodiment 3

[0075] The pumpkin oligosaccharide crude extract used in this example is the pumpkin oligosaccharide crude extract prepared in Example 1.

[0076] A method for refining pumpkin oligosaccharides by using macroporous resin, carried out according to the following steps:

[0077] (1) Macroporous resin pretreatment: soak DM28 macroporous adsorption resin in deionized water for 20 hours, wash with ethanol until it is not cloudy, soak in ethanol for 20 hours, wash with water until there is no alcohol smell, and use a NaOH solution with a mass percentage concentration of 5%. Pass through the resin column and soak for 1h, wash with water until neutral, pass HCl with a mass percentage concentration of 5% through the resin column and soak for 1h, wash with water until neutral, and set aside at 4°C; when in use, pack into a chromatography column (6cm×80cm) 3 / 4 places, to ensure that the filling is even and flat without air bubbles;

[0078] (2) Add water to the pumpkin oligosaccharide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com