Device and method for removing organic sulfur out of gas material

A gas material and organic sulfur technology, applied in the field of desulfurization, can solve the problems of increased investment, frequent replacement of solid hydrolysis catalysts and fine desulfurizers, large equipment footprint, etc., and achieve the effect of no discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

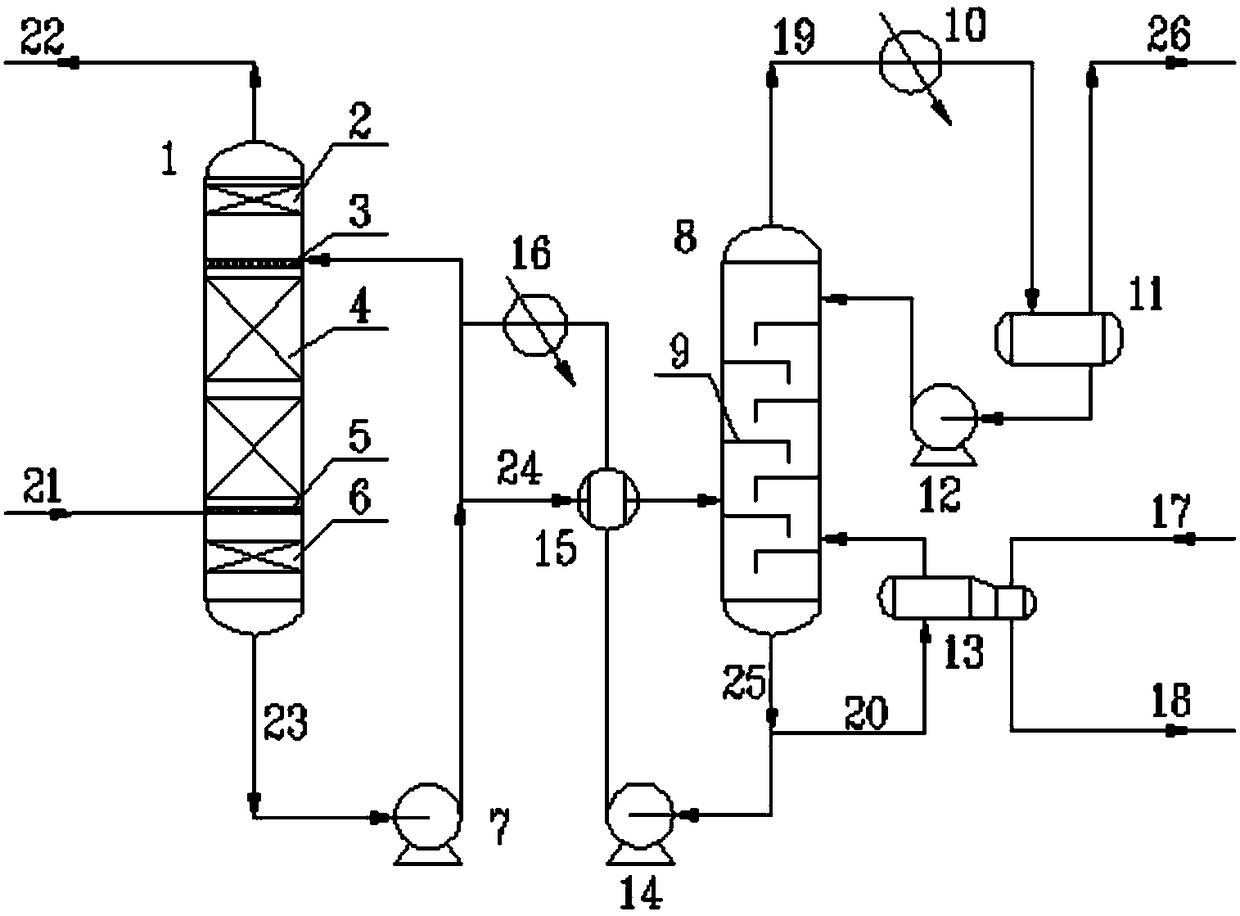

Image

Examples

Embodiment 1

[0046] A sample of natural gas produced in an oil and gas field, after extraction and desulfurization with amine solution, the total sulfur was 375mg / Nm 3 , of which the hydrogen sulfide content is 12mg / Nm 3 , adopt the inventive method to carry out desulfurization test, test result is as follows:

[0047] The test temperature of natural gas desulfurization is 24°C, after being treated by the experimental device of the method of the present invention, the total sulfur of natural gas is 5mg / Nm 3 .

Embodiment 2

[0049] A petrochemical company catalytic unit produces dry gas 15000-20000 Nm 3 / h, total sulfur 100-200mg / Nm after extraction and desulfurization by amine solution 3 , wherein the hydrogen sulfide content is less than 10mg / Nm 3 , adopt the method of the present invention to build a set of gas material removal device of organic sulfur, device operation result is as follows:

[0050] The operating temperature of the dry gas desulfurization extraction tower is 25-40°C, the pressure is 0.8-1.1MPa, and the total circulation flow rate of the desulfurizer is 12-15m 3 / h, send regeneration tower rich desulfurizer flow rate 2-3m 3 / h, the operating pressure of the regeneration tower is 0.12MPa, the temperature at the bottom of the regeneration tower is 115-120°C, the temperature at the top of the tower is 90-95°C, and the total sulfur in the dry gas after desulfurization does not exceed 10mg / Nm 3 .

[0051] In summary, with the aid of the above-mentioned technical scheme of the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap