Griseofulvin production strain culture medium

A culture medium, griseofulvin technology, applied in microorganisms, fungi, microorganism-based methods, etc., can solve the problem of high cost, and achieve the effects of reducing raw material costs, saving power, and shortening the cultivation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

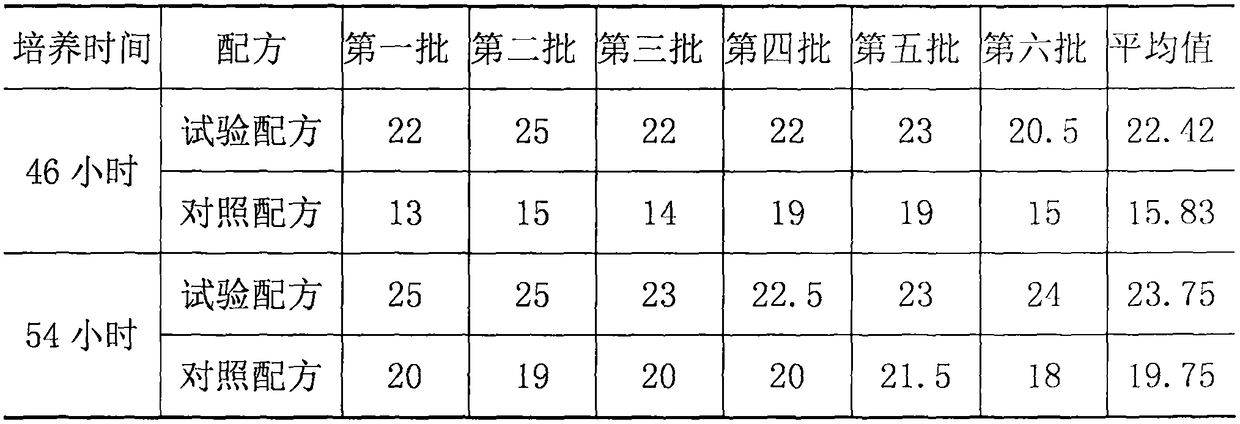

Method used

Image

Examples

Embodiment 1

[0012] Example 1: A culture medium for the production of griseofulvin, which is prepared from the following raw materials in parts by weight: 850 parts of water, 52 parts of corn flour, 3.5 parts of potassium dihydrogen phosphate, and 1.5 parts of sodium chloride , 1.2 parts of potassium chloride, 1.2 parts of ammonium sulfate, 1.5 parts of sodium nitrate, 1.5 parts of ferrous sulfate, 4 parts of calcium carbonate.

Embodiment 2

[0013] Example 2: A culture medium for the production of griseofulvin, which is prepared from the following raw materials in parts by weight: 720 parts of water, 35 parts of corn flour, 3 parts of potassium dihydrogen phosphate, and 1 part of sodium chloride , 1.5 parts of potassium chloride, 1.5 parts of ammonium sulfate, 2 parts of sodium nitrate, 2 parts of ferrous sulfate, 3 parts of calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com