A plastic electroplating roughening liquid recovery and circulation method and its application system at the edge of the line tank

A technology of plastic electroplating and roughening liquid, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problem of the inability to achieve efficient recovery and high-performance recycling of plastic electroplating roughening liquid, affecting the roughening and electroplating qualification rate of plastic parts, It is impossible to remove problems such as trivalent chromium ions and organic carbon, and achieve high-efficiency recovery and high-performance recycling, solve online recovery and recycling, and achieve good environmental protection and economic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

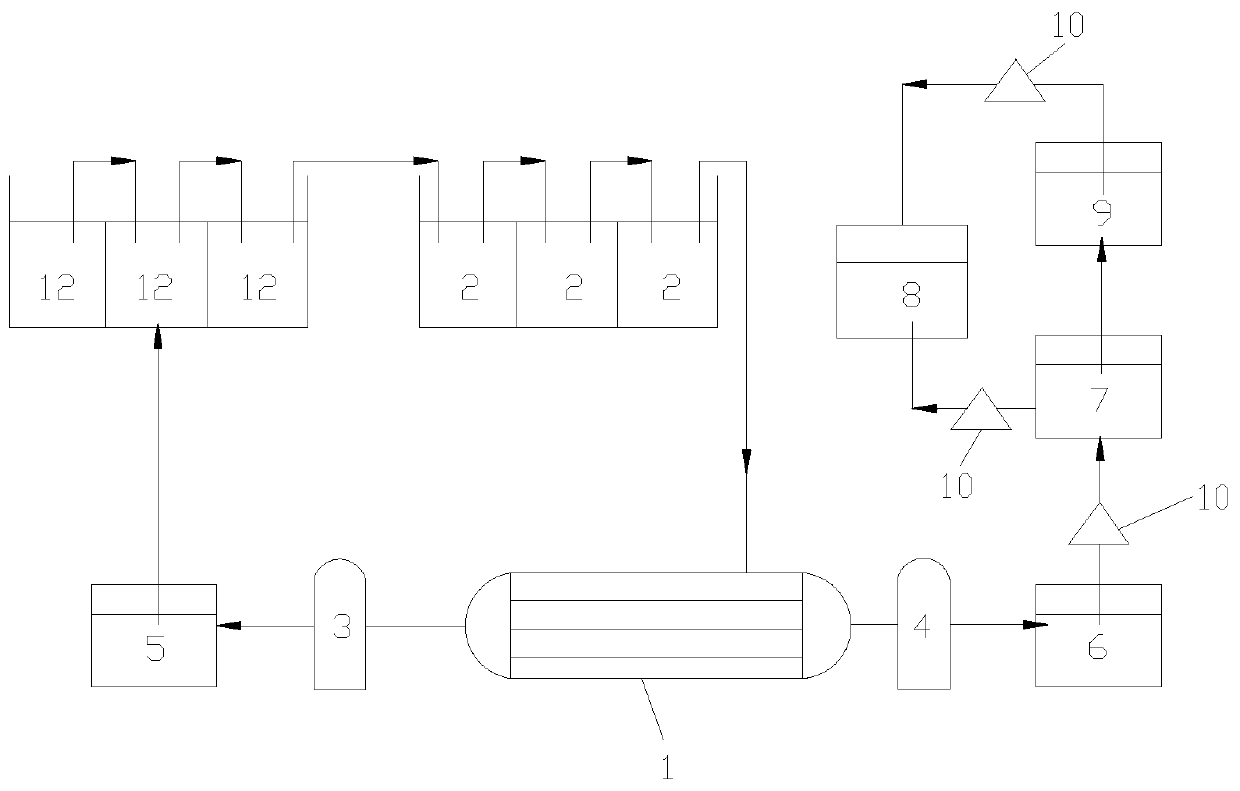

[0026] Such as figure 1 Shown, a kind of plastic electroplating roughening solution wire tank edge recovery and circulation method, comprises the following steps:

[0027] A. The low-concentration coarsening recovery liquid in the roughening liquid recovery tank 2 is pumped into or self-inhaled into the multi-stage decompression evaporator 1 through a metering pump. The working pressure of the multi-stage decompression evaporator 1 is 0.051-0.002MPa, so that The low-concentration roughened recovered liquid is evaporated, concentrated and separated under reduced pressure to obtain a high-concentrated roughened recovered liquid of not less than 700g / L, which is product A1, and evaporated condensed water, which is product A2;

[0028] B. Import the A2 product into the condensed water temporary storage tank 3, wherein the A2 product in the condensed water temporary storage tank 3 does not exceed 4 / 5 of the storage volume of the condensed water temporary storage tank 2, and then pu...

Embodiment 2

[0034] Such as figure 1 Shown, a kind of plastic electroplating roughening solution wire tank edge recovery and circulation method, comprises the following steps:

[0035] A. The low-concentration coarsening recovery liquid in the roughening liquid recovery tank 2 is pumped into or self-inhaled into the multi-stage decompression evaporator 1 through a metering pump. The working pressure of the multi-stage decompression evaporator 1 is 0.051-0.032MPa, so that The low-concentration roughened recovered liquid is evaporated, concentrated and separated under reduced pressure to obtain a high-concentrated roughened recovered liquid of not less than 700g / L, which is product A1, and evaporated condensed water, which is product A2;

[0036] B. Import A2 product into the condensed water temporary storage tank 3, and when the A2 product in the condensed water temporary storage tank 3 reaches 3 / 5 of the storage volume of the condensed water temporary storage tank 3, put the A2 product in ...

Embodiment 3

[0042] Such as figure 1 Shown, a kind of plastic electroplating roughening solution wire tank edge recovery and circulation method, comprises the following steps:

[0043] A. The low-concentration coarsening recovery liquid in the roughening liquid recovery tank 2 is pumped into or self-inhaled into the multi-stage decompression evaporator 1 through a metering pump. The working pressure of the multi-stage decompression evaporator 1 is 0.040MPa, so that the low-concentration The roughened recovery liquid is evaporated, concentrated and separated under reduced pressure to obtain a high-concentration roughened recovered liquid of not less than 800g / L, which is product A1, and evaporated condensed water, which is product A2;

[0044] B. Import A2 product into the condensed water temporary storage tank 3, and when the A2 product in the condensed water temporary storage tank 3 reaches 1 / 2 of the storage volume of the condensed water temporary storage tank 3, put the A2 product in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com