Preparation method of hollow light fishing net lines

A fishing net line and hollow technology, which is applied in the field of preparation of hollow light fishing net line, can solve the problems of limited space and achieve the effects of increasing surface area, improving bending resistance and wear resistance, and improving frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

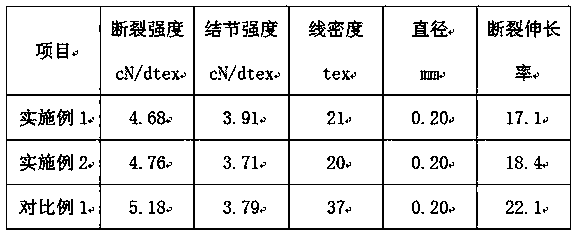

Examples

Embodiment 1

[0018] A method for preparing a hollow lightweight fishing net line, comprising the following steps:

[0019] (1) Add raw material composition, high-density polyethylene, solvent, antioxidant, mix uniformly at 80 ℃, described raw material composition includes polyethylene, solvent, antioxidant, described polyethylene and solvent have heat Liquid-liquid phase separation point, that is, when the mixture is cooled, the system can undergo thermal liquid-liquid phase separation at a temperature not lower than the crystallization temperature of polyethylene; the polyethylene is high-density polyethylene, and the The solvent described is one or any combination of white oil, kerosene, naphthenic oil, and fatty acid methyl ester; the coagulation liquid in the coagulation liquid tank is the same as the solvent; in the raw material composition, based on Described polyethylene and solvent, the weight fraction of polyethylene is 70wt%

[0020] (2) adopt spinning machine, described spinnin...

Embodiment 2

[0027] A method for preparing a hollow lightweight fishing net line, comprising the following steps: (1) adding a raw material composition, high-density polyethylene, a solvent, and an antioxidant, and mixing uniformly at 80° C., the raw material composition including polyethylene, Solvent, antioxidant, the polyethylene and the solvent have a thermotropic liquid-liquid phase separation point, that is, when the mixture is cooled, the system can undergo thermotropic liquid-liquid phase separation at a temperature not lower than the polyethylene crystallization temperature. phase separation; the polyethylene is a high-density polyethylene, and the solvent is one or any combination of white oil, kerosene, naphthenic oil, fatty acid methyl ester; the coagulation liquid in the coagulation liquid tank and The solvent is the same; in the raw material composition, based on the polyethylene and solvent, the weight fraction of polyethylene is 60wt%

[0028] (2) adopt spinning machine, de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com