Gel pyrolysis-based cobalt-nitrogen-doped carbon composite material and preparation method and application thereof

A composite material, nitrogen-doped carbon technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of limiting the electrochemical energy conversion efficiency and performance of fuel cells, high cost of platinum, sensitivity to methanol, etc., to achieve clever experimental design , high specific surface area, and high electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 1mmol melamine, 1mmol nicotinic acid and 0.025mmol cobalt acetate into 6mL, 5mL and 1mL deionized water respectively to obtain melamine solution, nicotinic acid solution and cobalt acetate solution, mix these three solutions at 90°C, and Stir vigorously for 10 min, then cool to room temperature to obtain a cobalt composite gel.

[0030] (2) Aging the cobalt composite gel in step (1) for 3 days, drying it in a lyophilizer for 48 hours to obtain a dry gel, and carbonizing it under high-purity argon at a high temperature, the carbonization temperature is 700°C, and the heating rate is 5°C / min, keep it for 2h after reaching the specified temperature, then stir and wash with 1mol / L hydrochloric acid for 6h, and dry in a vacuum oven at 60°C overnight to obtain a cobalt-nitrogen doped carbon composite material, which is denoted as Co-N-C. Composites are tested for mapping.

[0031] figure 1 , figure 2 And mapping test results show that the prepared gel is a ribbon...

Embodiment 2

[0033] (1) Add 1mmol melamine, 1mmol nicotinic acid and 0.025mmol cobalt acetate into 6mL, 5mL and 1mL deionized water respectively to obtain melamine solution, nicotinic acid solution and cobalt acetate solution, mix these three solutions at 90°C, and Stir vigorously for 10 min, then cool to room temperature to obtain a cobalt composite gel.

[0034] (2) Aging the cobalt composite gel in step (1) for 3 days, drying it in a lyophilizer for 48 hours to obtain a dry gel, and carbonizing it under high-purity argon at a high temperature, the carbonization temperature is 600°C, and the heating rate is 5°C / min, keep at the specified temperature for 2h, then stir and wash with 1mol / L hydrochloric acid for 6h, and dry in a vacuum oven at 60°C overnight to obtain a cobalt-nitrogen doped carbon composite material, denoted as Co-N-C-1.

Embodiment 3

[0036] (1) Add 1mmol melamine, 1mmol nicotinic acid and 0.025mmol cobalt acetate into 6mL, 5mL and 1mL deionized water respectively to obtain melamine solution, nicotinic acid solution and cobalt acetate solution, mix these three solutions at 90°C, and Stir vigorously for 10 min, then cool to room temperature to obtain a cobalt composite gel.

[0037] (2) Aging the cobalt composite gel in step (1) for 3 days, drying it in a freeze dryer for 48 hours to obtain a dry gel, and carbonizing it under high-purity argon at a high temperature, the carbonization temperature is 800°C, and the heating rate is 5°C / min, keep at the specified temperature for 2h, then stir and wash with 1mol / L hydrochloric acid for 6h, dry in a vacuum oven at 60°C overnight to obtain a cobalt-nitrogen doped carbon composite material, denoted as Co-N-C-2.

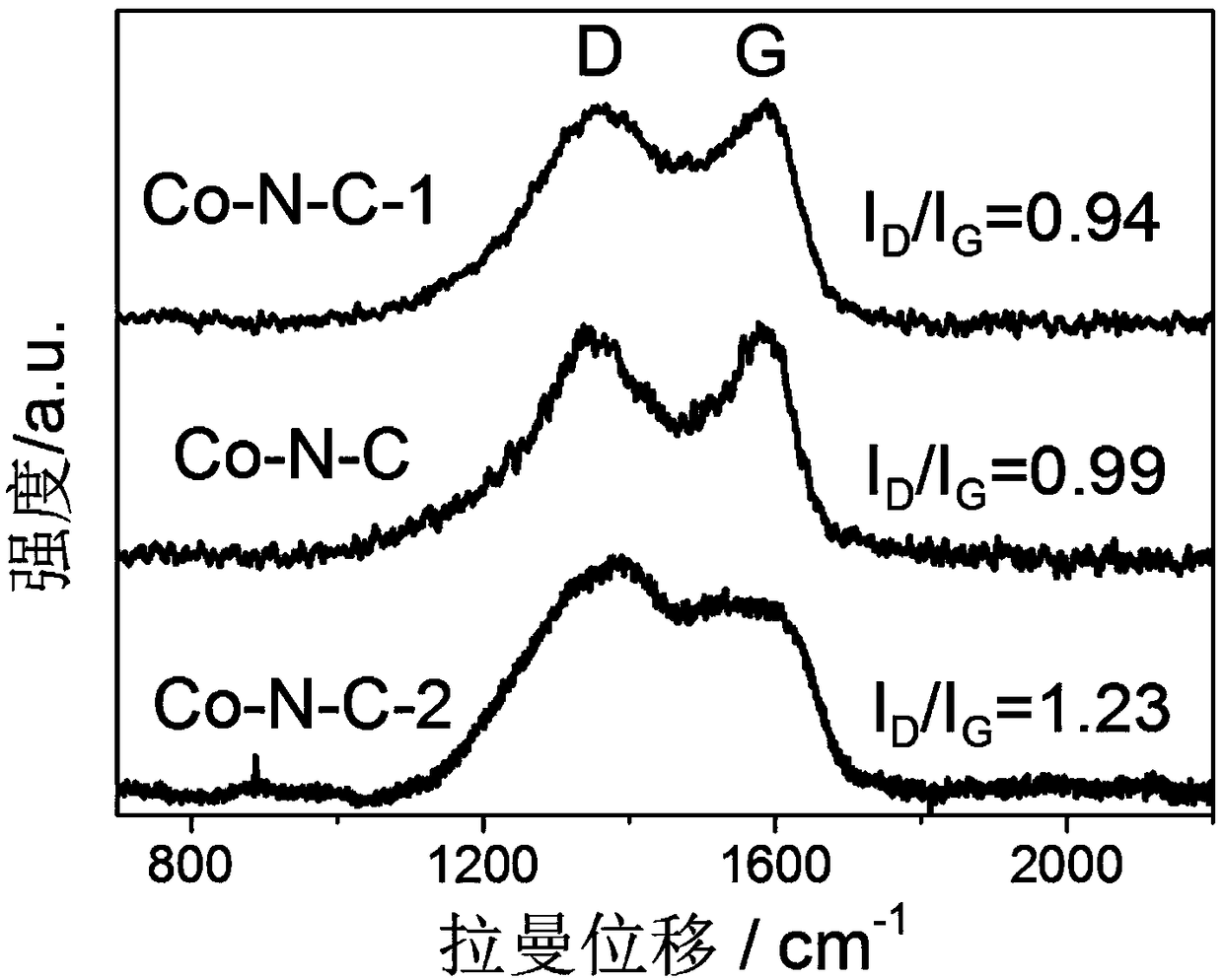

[0038] image 3 It shows that the pyrolysis degree of the prepared gel is not complete at 600℃, the degree of graphitization is low, and the conductivity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com