Method for preparing ovalbumin with high foaming by ultrasonic assisted glycosylation modification

A technology of ovalbumin and glycosylation, which is applied in the field of preparation of high-foaming ovalbumin by ultrasonic-assisted glycosylation modification, can solve the problems of long time required, easy by-product formation, and intense reaction, etc. Foam and foam stability, reducing protein thermal aggregation effect, improving foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

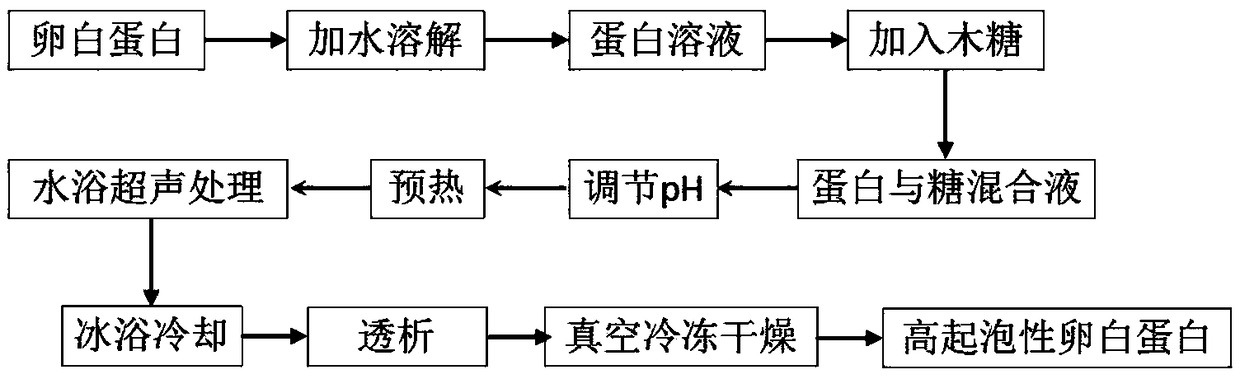

[0038] The method for preparing high foaming ovalbumin 1 by ultrasonic-assisted glycosylation modification comprises the following steps:

[0039] 1) adding ovalbumin powder into water to dissolve to obtain ovalbumin solution; wherein, the mass fraction of ovalbumin in the ovalbumin solution is 2%.

[0040] 2) adding xylose to the ovalbumin solution, stirring evenly, and adjusting the pH value to 8.0; obtaining a protein sugar solution; wherein, the mass fraction of xylose in the protein sugar solution is 1%;

[0041] 3) Put the proteoglycan solution in an ultrasonic device for pulse mode ultrasonic treatment for 30 minutes, the power is 300W, the ultrasonic frequency is 20kHz, the temperature of the constant temperature water bath is 40°C, and every working 5s, pause for 3s; obtain protein sample liquid;

[0042] 4) The protein sample solution was rapidly cooled to below 4°C in an ice bath, and then dialyzed in a refrigerator at a temperature of 4°C for 48 hours, then freeze-...

Embodiment 2

[0044] The method for preparing high foaming ovalbumin 2 by ultrasonic-assisted glycosylation modification comprises the following steps:

[0045] 1) adding ovalbumin powder into water to dissolve to obtain ovalbumin solution; wherein, the mass fraction of ovalbumin in the ovalbumin solution is 2%.

[0046] 2) adding xylose to the ovalbumin solution, stirring evenly, and adjusting the pH value to 8.0; obtaining a protein sugar solution; wherein, the mass fraction of xylose in the protein sugar solution is 2%;

[0047] 3) Put the proteoglycan solution in an ultrasonic device for pulse mode ultrasonic treatment for 30 minutes, the power is 300W, the ultrasonic frequency is 20kHz, the temperature of the constant temperature water bath is 55°C, and every working 5s, pause for 3s; obtain protein sample liquid;

[0048] 4) The protein sample solution was rapidly cooled to below 4°C in an ice bath, and then dialyzed in a refrigerator at a temperature of 4°C for 48 hours, then freeze-...

Embodiment 3

[0050] The method for preparing high foaming ovalbumin 3 by ultrasonic-assisted glycosylation modification comprises the following steps:

[0051] 1) adding ovalbumin powder into water to dissolve to obtain ovalbumin solution; wherein, the mass fraction of ovalbumin in the ovalbumin solution is 4%.

[0052] 2) adding xylose to the ovalbumin solution, stirring evenly, and adjusting the pH value to 6.0; obtaining a protein sugar solution; wherein, the mass fraction of xylose in the protein sugar solution is 4%;

[0053] 3) Put the proteoglycan solution in an ultrasonic device for pulse mode ultrasonic treatment for 30 minutes, the power is 400W, the ultrasonic frequency is 20kHz, the temperature of the constant temperature water bath is 55°C, and every working 5s, pause for 3s; obtain protein sample liquid;

[0054] 4) The protein-like liquid was rapidly cooled to below 4°C in an ice bath, and then dialyzed in a refrigerator at a temperature of 4°C for 48 hours, then freeze-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com