Biosoluble antibacterial ultrafine glass wool and preparation method thereof

A technology of ultra-fine glass wool and glass wool, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of life safety threats of production personnel and users, increased tumor morbidity rate, human health risks, etc., and achieve inhibition of growth and reproduction. , small diameter, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

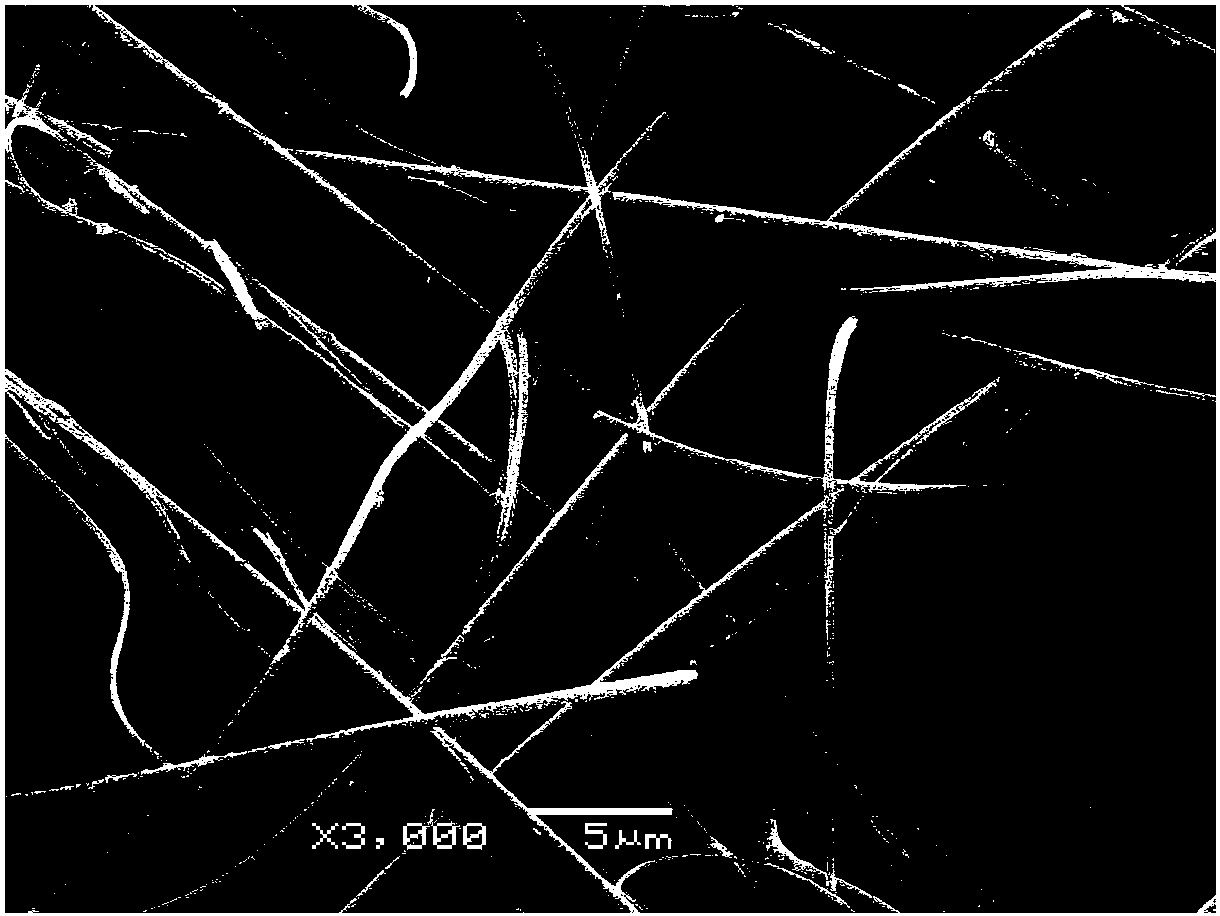

Image

Examples

Embodiment

[0031] Mix 360kg of quartz sand and 15kg of water in a mixer, then add 161kg of soda ash and 60kg of borax, and finally add 15kg of calcite, 85kg of dolomite, 38kg of feldspar, 8kg of zinc oxide, 32kg of silver nitrate and 135kg of broken glass in order, and stir and mix 4min, the rotation speed is 30rad / min; the above-mentioned mixture is melted, clarified and homogenized into liquid glass in a conventional horseshoe flame furnace, the melting temperature is 1340°C, and the clarification and homogenization temperature is 1100°C-1200°C; the above-mentioned liquid glass The glass is introduced into a high-speed rotating centrifuge for high-speed centrifugal fiberization. The root stream temperature of the liquid glass is 1040°C, the average temperature of the centrifuge is 980°C, and the rotation speed is 2900rad / min; the above-mentioned high-speed fiberized liquid glass is stretched by gradient high-temperature airflow , the temperature of the top airflow is 1400°C, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com